1

The motors on “DD” Series pumps are designed to be

used with either 115 or 230 volt supply by changing

connections as shown on the diagram.

Connecting the motor to the wrong

voltage can cause serious damage.

“Table 2” lists branch fuse size ratings and

recommended supply wire for each pump.

Grounding the motor

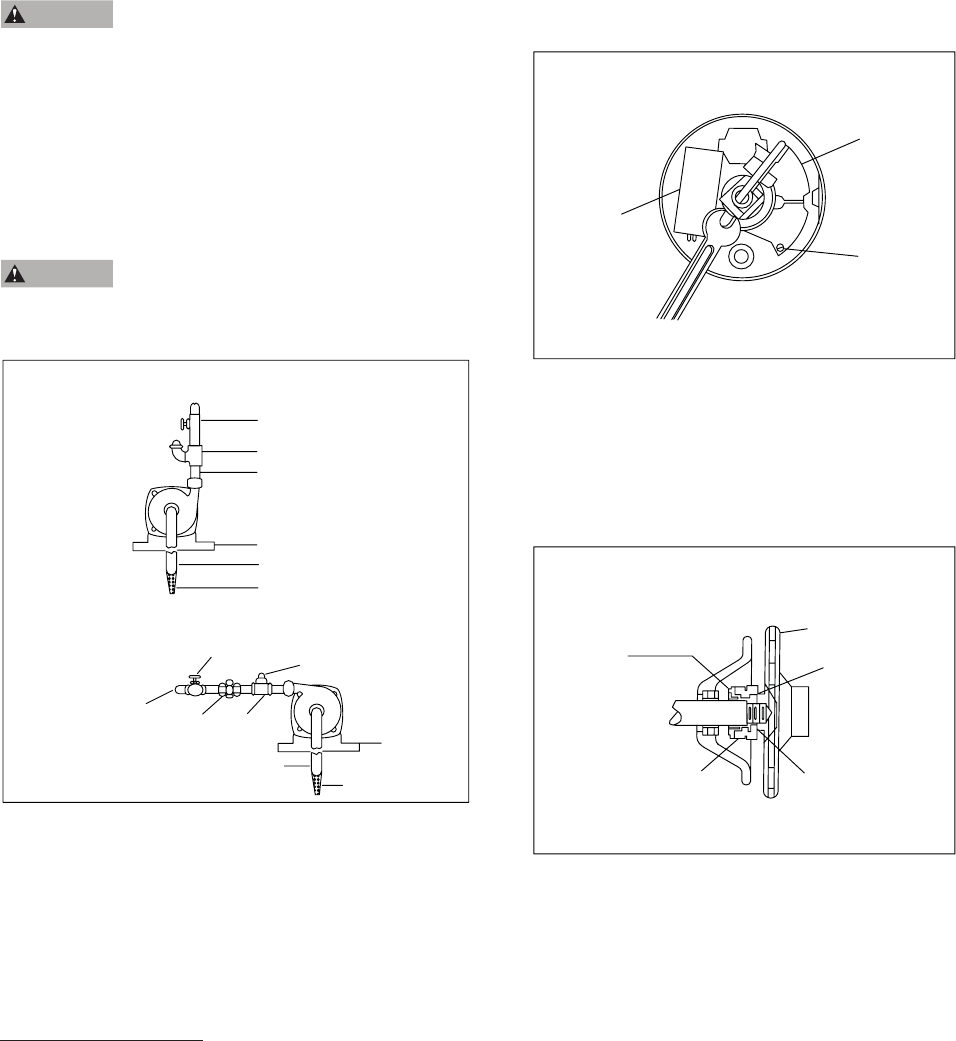

Make sure that the green lead wire is securely

connected to the green ground terminal screw on

the motor terminal board, “Fig. 1”. This wire must be

connected to the electrical system ground (provided by

the power company) or to another adequate ground.

Failure to ground the pump properly

can result in serious or fatal injury.

Typical Discharge Plumbing Options

Priming the Pump

Fill the pump and suction piping completely with water

before starting. Never operate the pump without water

in it. The mechanical shaft seal and impeller can be

damaged if run dry. If the pump does not deliver water

in 20 - 30 seconds, some air may be trapped. Stop the

pump, refi ll with water, and start again.

SERVICE THE PUMP

1. Remove the motor from the pump case.

2. Take off the motor end cover (canopy).

3. Remove the impeller from the motor. To keep the

motor shaft from turning while unscrewing the

impeller, hold shaft by inserting a 7/16” (11.1 mm)

open-end wrench at the 7 o’clock position of the

switch end of the motor, as shown in Figure1. The

motor shaft has fl at surfaces at that point.

Vertical Discharge

Horizontal Discharge

Gate Valve

Tee

Discharge Pipe

Base

Suction Pipe

Foot Valve

Gate Valve

Tee

Discharge Pipe

Base

Suction Pipe

Foot Valve

Priming Plug

Union

If any type of wrench must be used on the impeller, be

sure to protect the impeller surfaces by putting a shop

cloth or other protection between the wrench and the

impeller.

4. Remove the rotating part of the seal by fi rst removing

the square rubber drive ring (Figure 2) with a small

screwdriver or knife blade. The remainder of the

rotating portion is then loose and may be removed

easily.

5. Remove the seal plate, which is now free. Push

the seal seat out of the seal plate from the back

side. Clean the cavity, from which the seal seat was

removed. Also clean the motor shaft.

6. Replace the seal plate on the motor.

7. Dip the seal seat in a soap solution or clear water for

lubrication and install in the seal cavity. Press fi rmly in

place with fi ngers, If it cannot be positioned with the

fi ngers, put the cardboard washer (furnished with the

seal) on the seal face and press the seat in place with

a piece of pipe or other tool, as shown in (Figure 3).

Remove the cardboard washer and clean the polished

seal surface with a soft cloth. Be very careful not to

damage or scratch the surface.

CAUTION

CAUTION

Figure 1

Capacitor

Terminal

Board

Ground

Screw

Figure 2

Impeller

Impeller Hub

Rubber

Drive Ring

Face of

Sealing Washer

Shaft Shoulder