20

105192

UNVENTED PROPANE/LP GAS LOG HEATER

CLEANING AND

MAINTENANCE

WARNING: Turn off heater

and let cool before cleaning.

CAUTION: You must keep

control areas, burner, and circu-

lating air passageways of heater

clean. Inspect these areas of

heater before each use. Have

heater inspected yearly by a quali-

fied service person. Heater may

need more frequent cleaning due

to excessive lint from carpeting,

pet hair, bedding material, etc.

LOGS

• If you remove logs for cleaning, refer to

Installing Logs, page 14, to properly re-

place logs.

• Replace log(s) if broken or chipped

(dime-sized or larger).

MAIN BURNER

Periodically inspect all burner flame holes

with the heater running. All slotted burner

flame holes should be open with yellow

flame present. All round burner flame holes

should be open with a small blue flame

present. Some burner flame holes may be-

come blocked by debris or rust, with no

flame present. If so, turn off heater and let

cool. Remove blockage. Blocked burner

flame holes will create soot.

SERVICE HINTS

When Gas Pressure Is Too Low

• pilot will not stay lit

• burners will have delayed ignition

• heater will not produce specified heat

• propane/LP gas supply may be low

You may feel your gas pressure is too low.

If so, contact your local propane/LP gas

supplier.

TECHNICAL

SERVICE

You may have further questions about in-

stallation, operation, or troubleshooting. If

so, contact Fireplace Manufacturers

Incorporated’s Technical Service Depart-

ment at 1-866-672-6040.

You can also visit DESA International’s

Technical Service web site at

www.desatech.com.

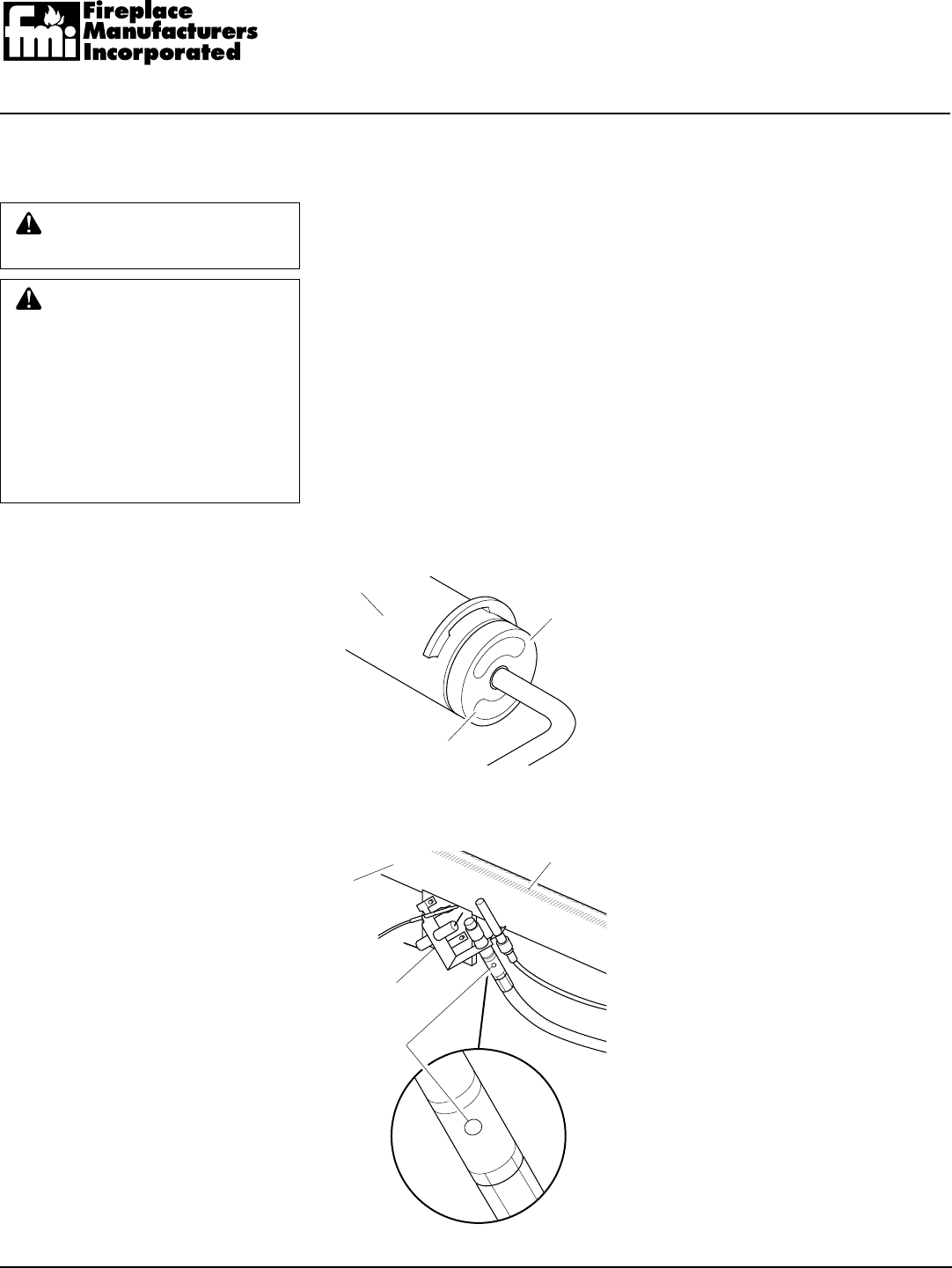

Figure 23 - Injector Holder On Outlet

Burner Tube

Burner

Tube

Injector Holder

(May Be Brass

or Aluminum

Depending on

Model)

Primary Air Inlet

Holes (Shape of

Holes May Vary

by Model)

Figure 24 - Pilot Inlet Air Hole

Burner

Tube

Pilot

Assembly

Pilot Air

Inlet

Hole

Ports/Slots

CLEANING BURNER

INJECTOR HOLDER AND

PILOT AIR INLET HOLE

The primary air inlet holes allow the proper

amount of air to mix with the gas. This

provides a clean burning flame. Keep these

holes clear of dust, dirt, lint, and pet hair.

Clean these air inlet holes prior to each

heating season. Blocked air holes will create

soot. We recommend that you clean the unit

every three months during operation and

have heater inspected yearly by a qualified

service person.

We also recommend that you keep the burner

tube and pilot assembly clean and free of

dust and dirt. To clean these parts we recom-

mend using compressed air no greater than

30 PSI. Your local computer store, hard-

ware store, or home center may carry com-

pressed air in a can. You can use a vacuum

cleaner in the blow position. If using com-

pressed air in a can, please follow the direc-

tions on the can. If you don't follow direc-

tions on the can, you could damage the pilot

assembly.

1. Shut off the unit, including the pilot.

Allow the unit to cool for at least thirty

minutes.

2. Inspect burner, pilot, and primary air

inlet holes on injector holder for dust

and dirt (see Figure 22).

3. Blow air through the ports/slots and

holes in the burner.

4. Check the injector holder located at the

end of the burner tube again. Remove

any large particles of dust, dirt, lint, or

pet hair with a soft cloth or vacuum

cleaner nozzle.

5. Blow air into the primary air holes on

the injector holder.

6. In case any large clumps of dust have

now been pushed into the burner repeat

steps 3 and 4.

Clean the pilot assembly also. A yellow tip

on the pilot flame indicates dust and dirt in

the pilot assembly. There is a small pilot air

inlet hole about two inches from where the

pilot flame comes out of the pilot assembly

(see Figure 23). With the unit off, lightly

blow air through the air inlet hole. You may

blow through a drinking straw if compressed

air is not available.