8

Section 08 TROUBLESHOOTING

8.10 VACUUM PROBLEMS Leakage, contamination, and unusual outgassing are the general causes of problems

associated with poor vacuum. To operate at maximum efficiency, a system must be thoroughly clean. It the system is

completely clean and free from leaks, and unwarranted vacuum problems still exist, the pump should be checked. A simple

criterion for the condition of the pump is the determination of its maximum vacuum capability. This can be accomplished by

blocking of the intake and reading the vacuum level on the gauge (See Section II-8).

8.20 PRESSURE PROBLEMS Leakage and contamination are the general causes of problems associated with poor

pressure. To operate at maximum efficiency a system must be thoroughly clean. If the system is completely clean and free

from leaks, and unwarranted pressure problems still exist, the pump/compressor should be checked by a service technician.

(See Section II-8).

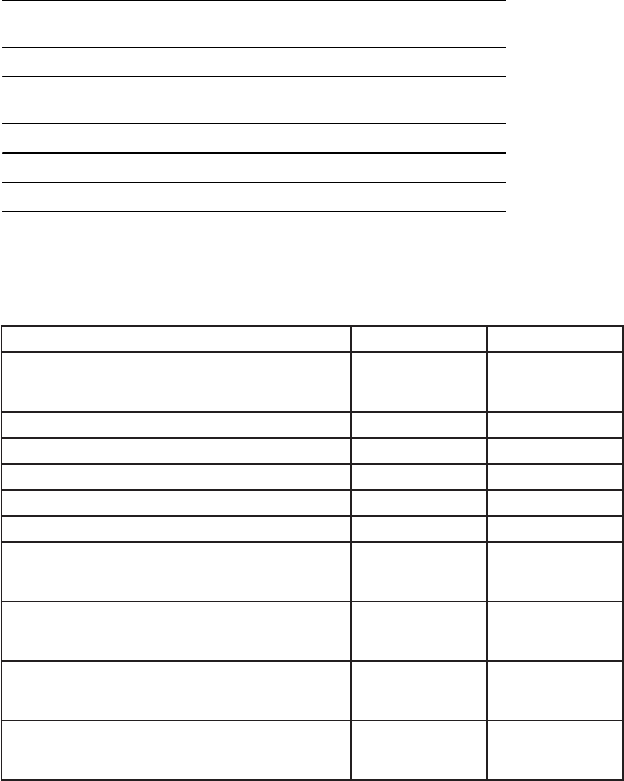

8.30 TROUBLESHOOTING GUIDE

Section 09 SPECIFICATION

Note: **50 Hz models provided with CE mark.

Poor Pumping

Speed

Poor

Pressure

Loud Unit Possible Cause Corrective Action

X X X Damaged Valves Replace flapper valves

X X X Debris in Valves

Remove debris and check

for valve damage

X X X Damaged Gaskets Replace gaskets

X X X Loose Head Screws Tighten head screws

X X Loose Fittings Tighten fittings

ledoMhcleW43526452

tnemecalpsiDriaeerF

zH06@)nim/L(MFC

zH05@)nim/L(MFC

)43(2.1

)82(0.1

)54(6.1

)73(3.1

)lacsaP(GISP.sserP.tnoC.xaM001001

)rroT(gH.ni,muucaV.xaV)59(2.62)76(3.72

rewopesroHrotoM7/13/1

.ni.D.I,dedeeNgnibuT4/14/1

)gkI.sbl,thgieW)3.5(7.11)3.6(8.31

rebmuNgolataC

esahP1,zH06,V511rofderiW

gulPV511naciremA.Nhtiw

10-B435110-B6452

rebmuNgolataC

esahP1,zH06,V032rofderiW

gulPV511naciremA.Nhtiw

10-C435210-C6452

rebmuNgolataC

esahP1,zH05,V022rofderiW

gulP)okuhcS(oruEhtiw

20-C435220-C6452

rebmuNgolataC

esahP1,zH06,V032rofderiW

gulPV052oruEhtiw

--