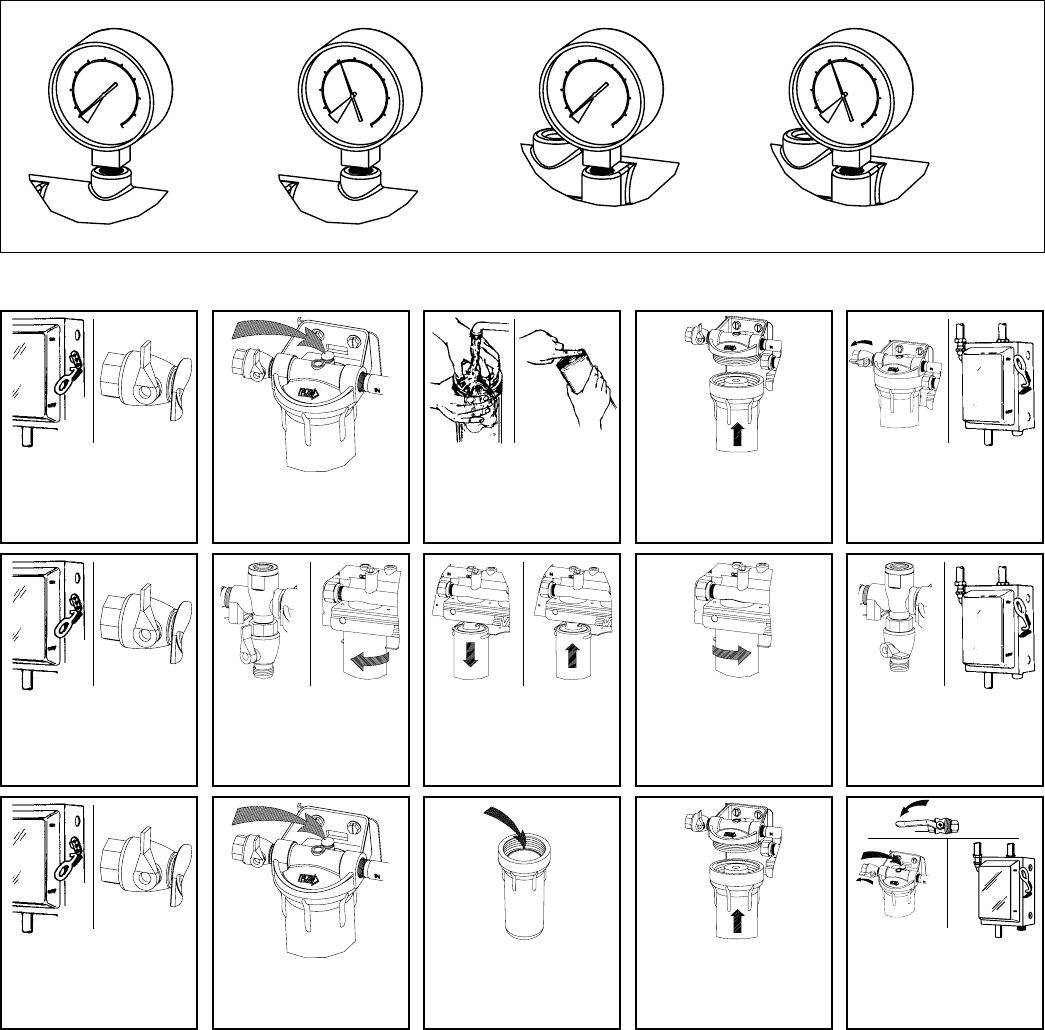

CARTRIDGE CHANGE PROCEDURE

E-Series Prefilter Cartridge Change

1. Shutoffpowertoequipment.Shut

off inlet water ahead of system.

2. Pushredreliefvalve.Unscrew

bowl.Removepreltercartridge.

3. Cleanbowlwithlteredwateronly;

NOSPECIALCLEANERS.

4. Feelheado-ring.Ifdry,lubricate

withhighqualitysiliconelubricant.

5. Installnewpreltercartridgein

bowl.Handtightenbowlontohead.

6. Turnonwater.Turnonpowerto

equipment.

Everpure Carbon Filter Cartridge

Change

1. Shutoffpowertoequipment.Shut

off inlet water ahead of system.

2. Openushingvalvetorelieve

pressure.

3. Hold head firmly and push upward.

Turncartridgetoleftuntilitstops.

4. Pullcartridgedownwardandoutof

head.

5. Holdheadrmly.Aligncartridge

lugwithlabel.Insertnewcartridge

firmly into head.

6. Turncartridgeright90˚until

rotation stops.

7. Repeatsteps3-6forremaining

cartridges.

Flushing

8. Withushingvalvefullyopen,open

inlet water at full force for five

minutes.Closeushingvalve.

9. Turnonpowertoequipment

PRESSURE GAUGES

Low Inlet

Pressure

Adequate Inlet

Pressure

Low Outlet

Pressure

Adequate Outlet

Pressure

SR-X Feeder Cartridge Change

1. Shutoffpowertoequipment.Shut

off inlet water ahead of system.

2. Pressredpressurereliefbuttonon

head.

3. Unscrewbowl.

4. Removeoldcartridge.

5. Feelbowlo-ring;ifdry,lubricate

withsiliconelubricant.

6. InstallnewSS-10cartridgeinto

head.

7. Handtightenbowlintohead.

8. Turnonwater.

9. Pressredpressurereliefbutton

until water comes out of valve port.

10.Turnonpowertoequipment.

For installations in Massachusetts, the Commonwealth of Massachusetts Plumbing Code 248 CMR shall be adhered to. Consult your licensed

plumber for installation of the system. This system and its installation must comply with state and local regulations.

CARTRIDGE CHANGE DETERMINATION

Replacethepreltercartridgewheneveritbecomesexcessivelydirty(observedvisuallyorbyowrestriction).Followthechangeinstructionsprovidedwith

thecartridge.Replacecarbonltercartridgeswhencapacityisreachedorwhenowbecomesinadequate,butatleastannually.Allcarbonltercartridges

onmultiplecartridgesystemsshouldbechangedatthesametime.ChangetheSS-10cartridgewhenproductlevelinthecartridgedropsbelow1/2"from

thebottomofthebowl.

ThesystempressuregaugeoroptionalEverguard

™

LowPressureAlarm(LPA)providesaquick,simplemeansofdeterminingwhentheltercartridge(s)

shouldbechecked.Installedonthesystemoutletmanifold,thegaugeorLPAcanbeusedtomonitorbothdynamic(owing)andstatic(line)pressure.The

cartridge(s)shouldbechangedwhenthepressuregaugeisintheredareawhileequipmentisinoperation,andyettheneedleshowsadequatelinepressure

betweencycles.Observetheneedleduringthenextequipmentoncycle.Iftheneedleregistersadequatepressure,itcanbeassumedthatthetemporary

low-pressureconditionwascausedbyabriefpowerfailureorotherincomingpressuredisruption.Ifthelowpressureconditionisnotduetoanexternal

condition,check/changetheprelterrst.Ifthelowpressureconditionisstillnotcorrected,changethecarbonltercartridges.