2

ADDITIONAL IMPORTANT SAFEGUARDS

1. To avoid circuit overload, do not operate another appliance on the same socket

(circuit) as the steam cleaner.

2. If an extension cord is absolutely necessary, an extension cord rated a minimum

of 15 ampere, 14 gage cord should be used. Cords rated for less amperage may

overheat. Care should be taken to arrange cord so that it cannot be pulled or

tripped over.

3. Do not leave unattended when the system is connected to a power

supply/electrical outlet.

Warning: This appliance is equipped with a grounded-type 3-wire cord

(3-prong plug). This plug will only fit into an electrical outlet

made for a 3-prong plug. This is a safety feature. If the plug

should fail to fit the outlet, contact an electrician to replace

the outlet. Do not attempt to defeat the safety purpose of

the grounding pin, part of the 3-prong plug.

Caution: The force and heat of the steam may adversely affect certain materials.

Always check the suitability of using the steam cleaner on a surface by

carrying out a preliminary test on a hidden area.

Examples for guidance only:

• Varnished wood or glossy leather can be bleached by

the effects of steam.

• Shiny plastic materials risk being tarnished.

• Acrylic, velvets and linen are very sensitive to the

temperature of steam.

The manufacturer accepts no responsibility for damage caused to objects,

materials, animals or persons due to the inappropriate use of steam, and through

ignoring the advice and recommendations set down in the Owner's Manual.

Maintenance & Cleaning

Instructions

Caution: This appliance must be

unplugged from the electrical outlet and

allowed to cool down before all

cleaning and maintenance tasks.

• Let the appliance cool down

completely before cleaning or

storing.

• Empty all water from the water tank

after each use.

• Store in a dry, cool place.

• A periodic rinse of your steam

cleaner will free it from deposits. This

is recommended every 10-15 tank-

fulls to free up any scale

deposits. Fill the boiler with water

and shake vigorously. Tilt the cleaner

upside down to empty the boiler of

water and any scale deposits.

Cleaning the Nozzles

Your steamer should not normally

require cleaning, however, should you

notice a marked decrease in steam

output it may be necessary to remove

mineral deposit build-up from the

nozzle orifice. First ensure that there is

water in the tank.

If tank is empty, fill with water, (we

recommend using purified or distilled

water), then re-start unit noting whether

steam output is normal. If steam output

is still low, follow these cleaning

instructions:

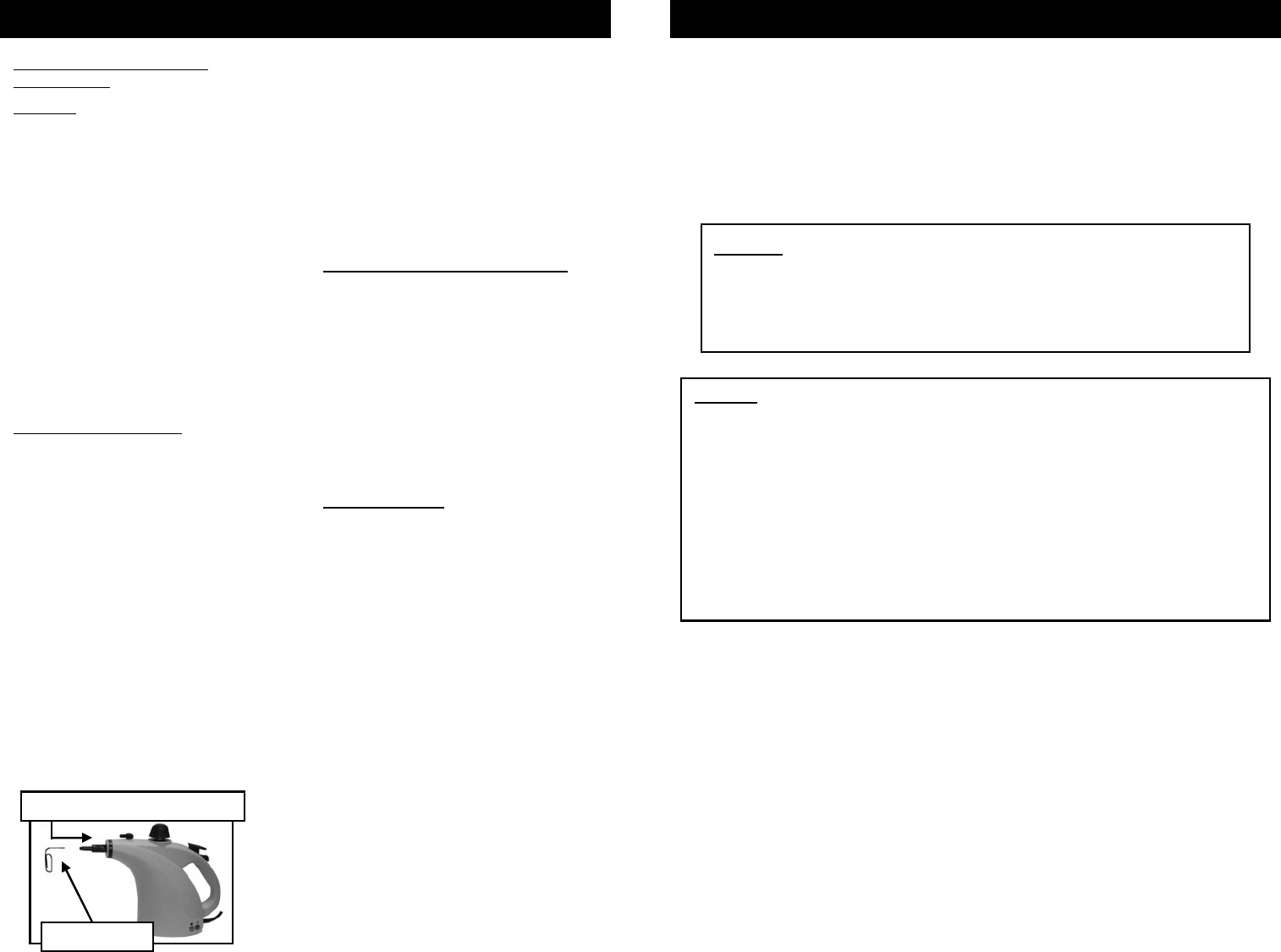

1. Unplug steam cleaner from wall

outlet.

2. Use a small diameter stiff metal

wire such as a straightened metal

paperclip and carefully insert the

end of the wire into the nozzle

orifice. (Fig. 10)

Maintenance & Cleaning Instructions

9

3. Move wire back and forth several

times to remove any deposits.

4. Reconnect appliance to power

outlet, assure that the variable

steam adjustment is in the

maximum flow position, depress

the trigger and note steam output.

5. If steam performance does not

improve, descale your steam

cleaner and then repeat steps #1

through #4.

Descaling Your Steam Cleaner

If the tap water in you area contains a

high level of calcium deposits and you

have been using tap water to do your

steam cleaning, you should descale

your unit after 10-15 tankfulls.

1. Unplug the steam cleaner from the

power source before you descale

the boiler. Allow to cool.

2. Fill the boiler with 1 part vinegar

and 5 parts water and leave

overnight or for a period of

approximately 8 hours.

Important Note: Do not screw the

safety cap onto the steam cleaner while

you are descaling the boiler. Do not

use the steam cleaner while

descaling solution is inside the

boiler.

3. After the period of soaking, turn

the steam cleaner upside down to

empty solution from the boiler. Due

to the fact that a small amount of

solution will be left in the boiler, it is

necessary to rinse the boiler out

with clean water 2 or 3 times. Your

steam cleaner is now ready for use.

Paper Clip

Insert paper clip into nozzle

Fig. 10