11

ENVISION SERIES AIR HANDLER INSTALLATION MANUAL

Hydronic Models

Flow gpm

Pressure Drop (PSI)

40°F 50°F 60°F 100°F 110°F 120°F 130°F

3.0 0.5 0.5 0.5 0.4 0.4 0.4 0.4

4.5 0.9 0.9 0.9 0.8 0.8 0.8 0.8

6.0 1.4 1.4 1.4 1.2 1.2 1.2 1.2

9.0 2.8 2.6 2.5 2.4 2.4 2.4 2.3

12.0 4.6 4.4 4.2 4.0 4.0 4.0 3.9

15.0 7.0 6.8 6.6 6.0 6.0 5.9 5.8

Water Presure Drop - Hydronic Coil

Entering Water Temperature °F

EAT °F 100 110 120 130 140 150

65

44% 56% 69% 81% 94% 106%

70

37% 50% 63% 75% 87% 100%

Coil Capacity vs. Entering Water Temperature

Electrical Data

All field wiring must comply with local and national fire,

safety and electrical codes. Be sure the available power is

the same voltage and phase as that shown on the unit serial

plate. Refer to the unit Electrical Data table for fuse and cir-

cuit breaker sizing. The thermostat should be connected to

the air handler and to the compressor section. Line voltage

power should be supplied to the breakers on air handlers

with 15kW and 20kW heater kits (see the electric heat

control section picture). On air handlers with no electric

heat installed, or with 5kW and 10kW heater kits the power

should be supplied to L1 and L2 lugs on PB (see air handler

control section picture).

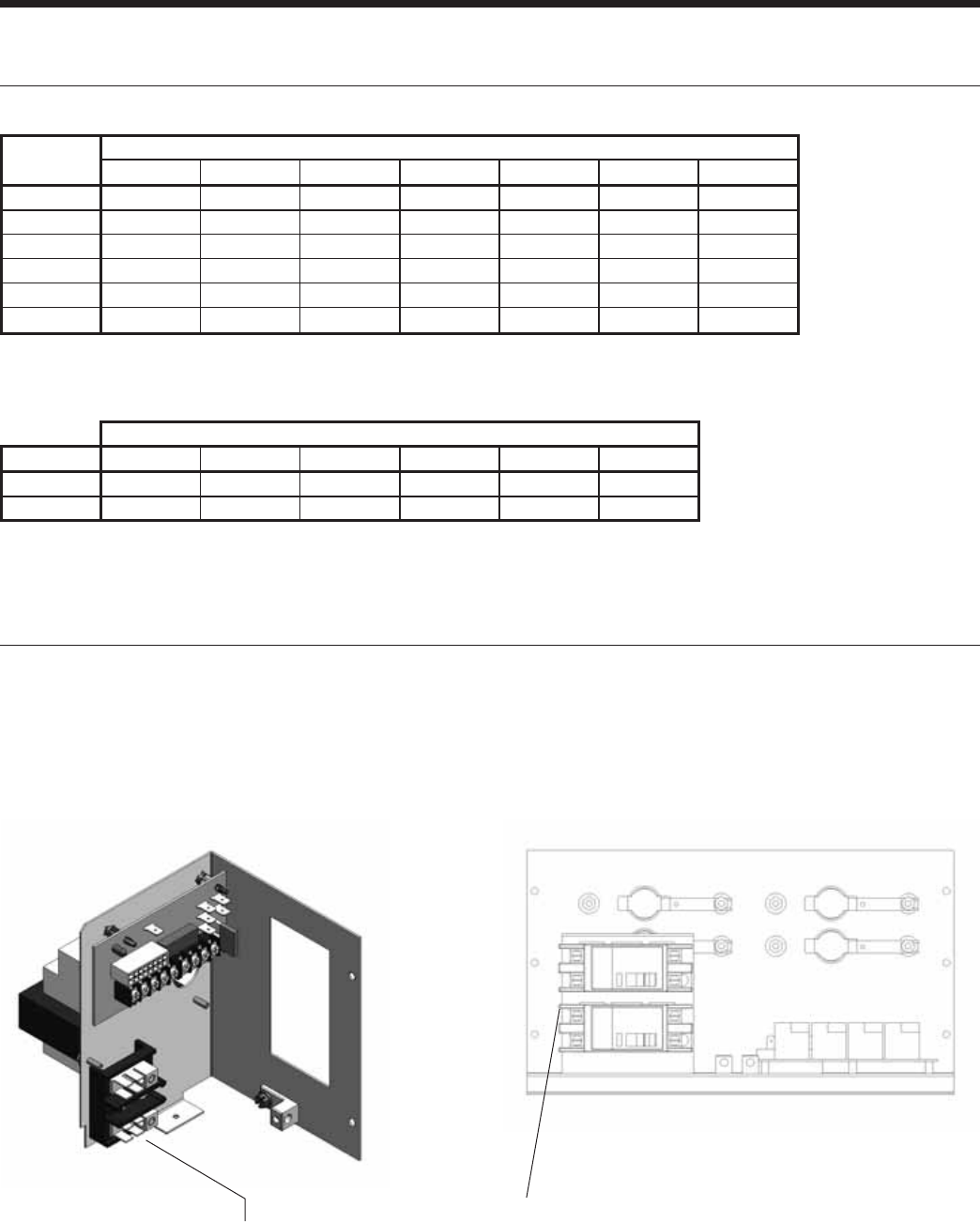

Air Handler Control Section:

Power should be supplied to PB on air handlers with no

electric heat and 5kW or 10kW heaters.

Electric Heat Control Section:

Power should be supplied to the breakers on air handlers

with 15kW and 20kW heaters.