4

Enerco | enerRadiant® XL Series Heater Operating Instructions and Owner’s Manual

• When installed over hoists, minimum

clearances to combustibles must be main-

tained from the uppermost point on the

hoist.

Electrical: The heater must be electrically grounded in

accordance with the National Electrical Code,

ANSI / NFPA-70 – latest revision. Wiring must

conform to the most current National Electrical

Code, local ordinances, and any special

diagrams furnished.

Venting: The venting must be installed in accordance

with NFPA-54 / ANSI Z223.1 – latest revision,

National Fuel Gas Code. Partial information

with regard to this code is provided in

(Section 5) of this installation manual with

regard to size and congurations for venting

arrangements.

• Any portion of ue pipe passing through

a combustible wall must be dual insulated

or have an approved thimble. Refer to

ANSI-Z223.1 – latest revision.

Hazardous

Locations: Where there is the possibility of exposure to

combustible airborne material or vapor, consult

the local Fire Marshal, the re insurance

carrier or other authorities for approval of the

proposed installation.

Critical Considerations

Ener-Radiant ERXL is a suspended heater.

Therefore, its stability, exibility, and safety are

very important. Before starting installation,

be sure the system can meet the following

requirements.

• Maintain specied clearances to combus-

tibles, and safe distance from the heat-

sensitive material, equipment and work

stations.

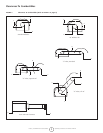

• Provide a suspension with vertical length

of chain or swinging rod which has at

least 2 inches of horizontal travel for

each burner in a straight run. Be sure the

suspension system is sufciently exible to

accommodate thermal expansion which

occurs as the system heats up (see

Figure 5 on page 15).

• Provide access to burners for servicing,

preferable on both sides, above and be-

hind the burner for removal.

• Provide a minimum of 18 inches of clear-

ance between burners and building walls.

(Always observe minimum clearances to

combustibles.)

• Be sure the heater has a downward pitch

of one-half inch per 20 feet away from the

burner.

• Provide signs in storage areas to specify

maximum stacking height to maintain

required clearances to combustibles.

• Plan location supports (see Figure ?).

Locate a support near all elbows.

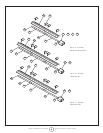

Installation Procedure

Take maximum advantage of the building

upper structure, beams, joists, purlins, etc.,

from which to suspend the heater. There is no

unique sequence for installation of the tubing.

On-site observation will usually reveal a logical

sequence. Begin the installation at the most

critical dimension. This could save time. Watch

for swinging doors, overhead cranes, car lifts,

etc. Reectors and tubing can be installed as

you move along. Carefully adjust system pitch

at each position to level the heater. Pitch down

one-half inch in 20 feet (away from burner).

Don’t Pressure test the gas line using high pressure

(greater than ½ PSIG) without closing the

high-pressure shutoff cocks. Failure to do so

will result in damage to the burners.

DO Familiarize yourself with local and national

codes.

Develop a planned procedure which will

conserve material and labor on the job.

Check to see that all material and equipment is

on the job before starting installation.

Allow for thermal expansion of the hot tube.

Install the gas connector only as shown in

instructions (see Figure 17).

Have slip joints where required between

reectors to keep them from buckling or

coming apart.

Provide 1 sq. inch of free air opening to each

1,000 BTU/hr. of heater input (but not less

than 100 sq. inches) in enclosed spaces. One

opening should be within 12 inches of the top

and one within 12 inches of the bottom of the

enclosure.