Page 19

12409-2-0403

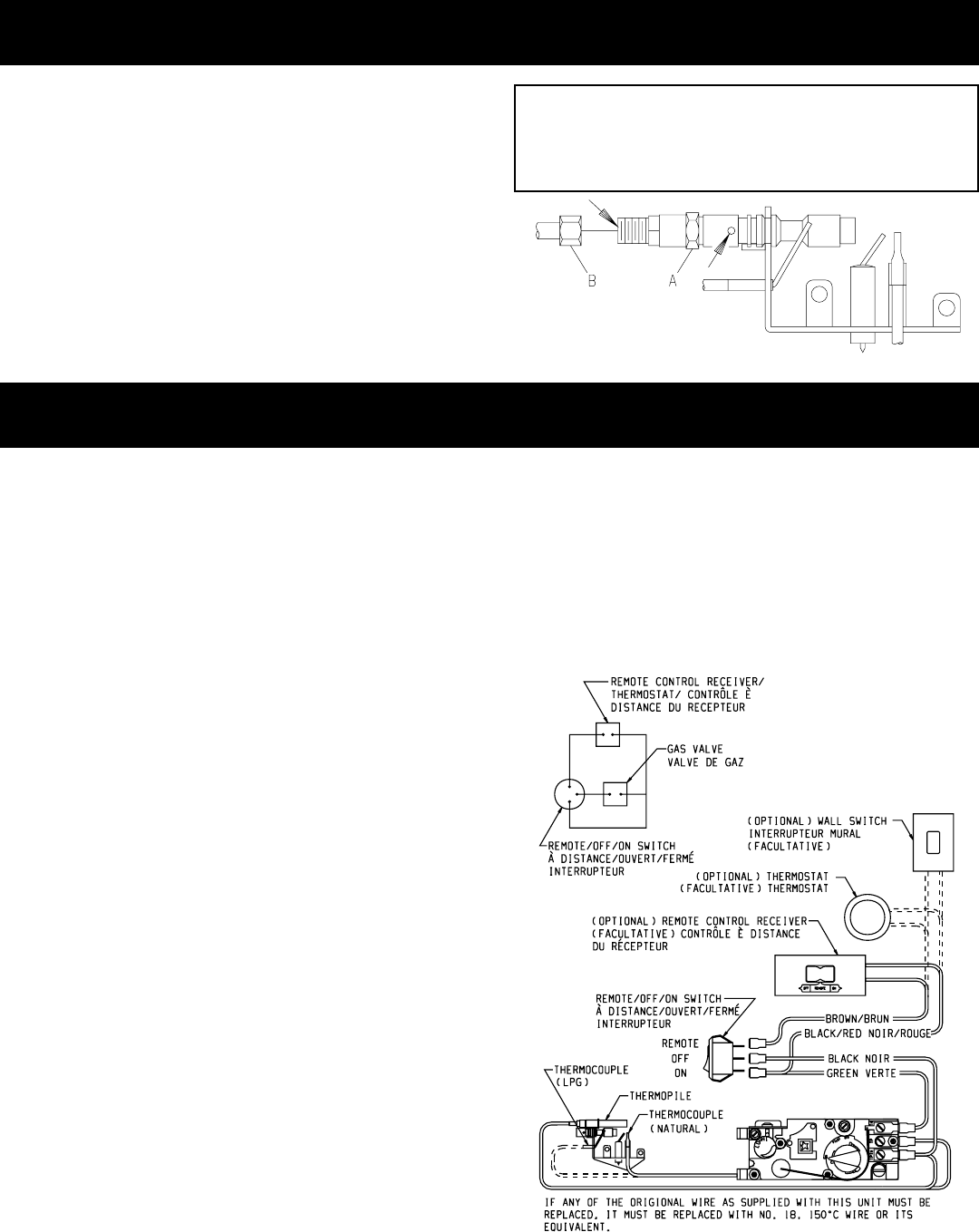

WIRING

Millivolt Control

The valve regulator controls the burner pressure which should be

checked at the pressure test point. Turn captured screw counter

clockwise 2 or 3 turns and then place tubing to pressure gauge

over test point (Use test point “A” closest to control knob). After

taking pressure reading, be sure and turn captured screw clock-

wise firmly to re-seal. Do not over torque. Check for gas leaks.

Wiring Diagram (Figure 25)

Label all wires prior to disconnection when servicing controls.

Wiring errors can cause improper and dangerous operation. Verify

proper operation after servicing.

16", 18", 24" and 30" Gas Logs (Millivolt) thermopile is self pow-

ered gas valve and does not require 110 volts. Refer to (Figure

25) to provide optional wall switch, thermostat, or remote con-

trol. Maximum length of 20 feet of 18 AWG to conductor wires is

to be used with all optional switches.

Use the two leads (Red and Green wires) to attach optional com-

ponents.

Check System Operation

Millivolt system and all individual components may be checked

with a millivolt meter 0-1000 MV range.

Remote Receiver -VFYR-(16, 18, 24, 30)

Use the following steps to place the remote receiver adjacent to

the gas valve.

Attention:

1. The remote receiver can not be placed behind the gas valve

and burner assembly.

2. When facing the appliance, the remote receiver must be placed

to the right of the gas valve and burner assembly.

Note: Do not let remote control receiver come in contact with

burner assembly.

On circulating vent-free firebox, install remote control receiver

behind bottom louver.

Refer to remote control installation and operating instructions for

more details on remote control.

750 Millivolt System

When you ignite the pilot, the thermocouple produces millivolts

(electrical current) which energizes the magnet in the gas valve.

After 30 seconds to 1 minute time period you can release the gas

control knob and the pilot will stay ON. Allow your pilot flame

to operate an additional one (1) to two (2) minutes before you turn

the gas control knob from the PILOT position to the ON position.

This time period allows the millivolts (electrical current) to build-

up to a sufficient level allowing the gas control to operate

properly.

Figure 25

Cleaning and Maintenance/Pilot

Oxygen Depletion Sensor Pilot (Figure 24)

When the pilot has a large yellow tip flame, clean the Oxygen

Depletion Sensor as follows:

1. Clean the ODS pilot by loosening nut B from the pilot

tubing. When this procedure is required, grasp nut A with

an open end wrench.

2. Blow air pressure through the holes indicated by the arrows.

This will blow out foreign materials such as dust, lint and

spider webs. Tighten nut B also by grasping nut A.

Warning:

Never use needles, wires, or similar cylindrical objects

to clean the pilot to avoid damaging the calibrated ruby

that controls the gas flow.

Figure 24

PILOT FLAME CHARACTERISTICS (continued)