13117-9-0907Page 10

Installing Vent Assembly

Attention: Do not attempt to cut vent tubes. When you order appropriate

vent kit for measured wall depth, the vent tubes will fit together.

1. Place provided caulking beneath the collar of the outside mounting

plate. Use additional caulking to correct uneven wall surface, such

as clapboard.

2. Insert six inch air tube on outside mounting plate INTO six inch air

tube attached to inlet air drop chute. Place four inch flue tube on

vent cap OVER four inch flue tube attached to combustion cham-

ber. Position the outside mounting plate so that six inch air tube

has a slight downward slope to the outside. The downward slope

is necessary to prevent the entry of rainwater. Attach outside

mounting plate to exterior wall with four (4) 10 x 1 1/2" screws.

3. Installation is completed.

Reassembly And Resealing Vent-Air Intake System.

When vent-air intake system is removed for service the furnace, the fol

-

lowing steps will assure proper reassembly and resealing of the vent-air

intake assembly.

1. Remove old caulking beneath the collar of the outside mounting

plate. Apply new caulking beneath the collar of the outside mount

-

ing plate. Use additional caulking to correct uneven wall surface,

such as clapboard.

2. Insert six inch air tube on outside mounting plate INTO six inch air

tube attached to inlet air drop chute. Position the outside mounting

plate so that the six inch air tube has a slight downward slope to the

outside. The downward slope is necessary to prevent the entry

of rainwater. Attach outside mounting plate to exterior wall with

four (4) 10 x 1 1/2" screws.

3. Place four inch flue tube on vent cap OVER four inch flue tube at-

tached to combustion chamber. Attach vent cap to outside mount-

ing plate with three (3) 10 x 1/2" screws.

4. Reassembly and resealing vent-air intake system is completed.

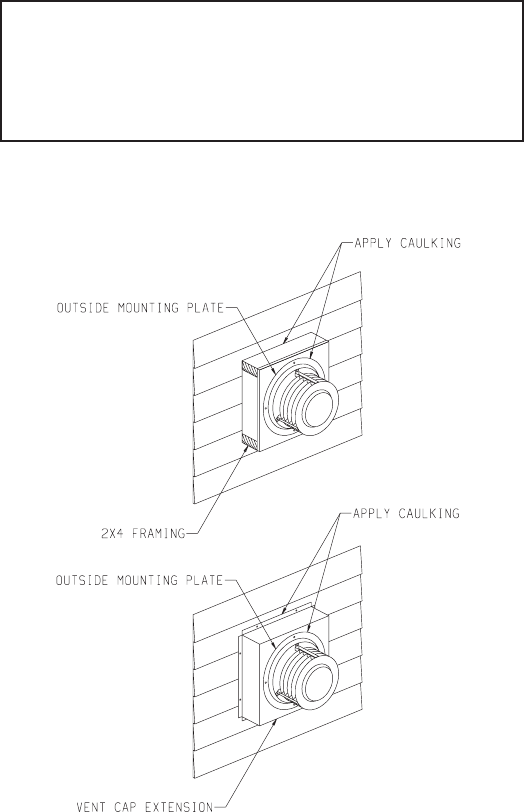

Installing a Vent Near a Window Ledge,

Other Type of Project or on Siding (vinyl, aluminum, etc.)

Direct vent furnaces are designed to be installed on a uniform outside

wall. When the wind comes from any angle (up, down, or from either

side), it must hit the vent cap equally over both the air inlet and the flue

outlet portions of the vent. Any wall projection, such as a door or win

-

dow casing, which disturbs the wind on one side of the air inlet section

will result in back pressure on the flue section smothering the flame and

eventual pilot outage.

When the vent cap is to be installed on siding, or it appears that a pro

-

jection within 6" of any side of the air inlet section could shield the air

inlet section, the entire vent should be supported away from the wall

at least the distance of the projection. 2" x 4" framing whose outside

dimensions match the overall dimensions of the mounting plate is rec-

ommended. The 2" x 4" framing protects siding from possible warpage

or discoloration. All joints can then be sealed and painted. The wall

depth plus the additional depth of the 2" x 4" framing should not exceed

a total depth of 19" for DV-25T and DV-35T (See Figure 7) (Refer to

Vent Kits page 3).

Figure 8

Vinyl siding vent kit, DV-822, is available from Empire Comfort Sys

-

tems, Inc. The depth is 3", which enables the vent cap to be extended

away from siding or projections. The wall depth plus the additional 3"

depth of the vinyl siding vent cap extension should not exceed a total

depth of 19" for DV-25T and DV-35T. (See Figure 8) (Refer to Vent Kits

page 3)

Warning: When vinyl siding vent kit, DV-822 or 2" x 4" fram-

ing is added to an existing installation (furnace is installed),

do not attempt to add sections of pipe to the flue outlet tube

or air inlet tube. An air tight seal is required for both tubes.

Refer to Vent Kits, page 3 to order tubes.

Figure 7