FLEXIBLE PIPE INSTALLATION

FITTING THE APPLIANCE AND CABINET

It is recommend that a

3

/8", 1100mm long

angled flexible hose (BFS), and a ½" straight

socket (BFS) be used for the installation.

However, any approved hose of the right length

can be used.

IMPORTANT: Flexible tubing used must comply

with BS 669 current editions. L.P.G. flexible

connections must be of a type suitable for

L.P.G. and capable of operation up to 50mbar

and carry a red stripe, band or label.

NOTE: Only liquid sealants can be used in

threaded gas connections. Do not use P.T.F.E.

tape.

1 Make suitable arrangements for gas and

electric supplies into the installation site.

2 When unpacking the appliance keep it on

its polystyrene base until it is put into the

cabinet to avoid damage.

NOTE: It is imperative that the appliance

is left in the base to protect both the

appliance and the floor.

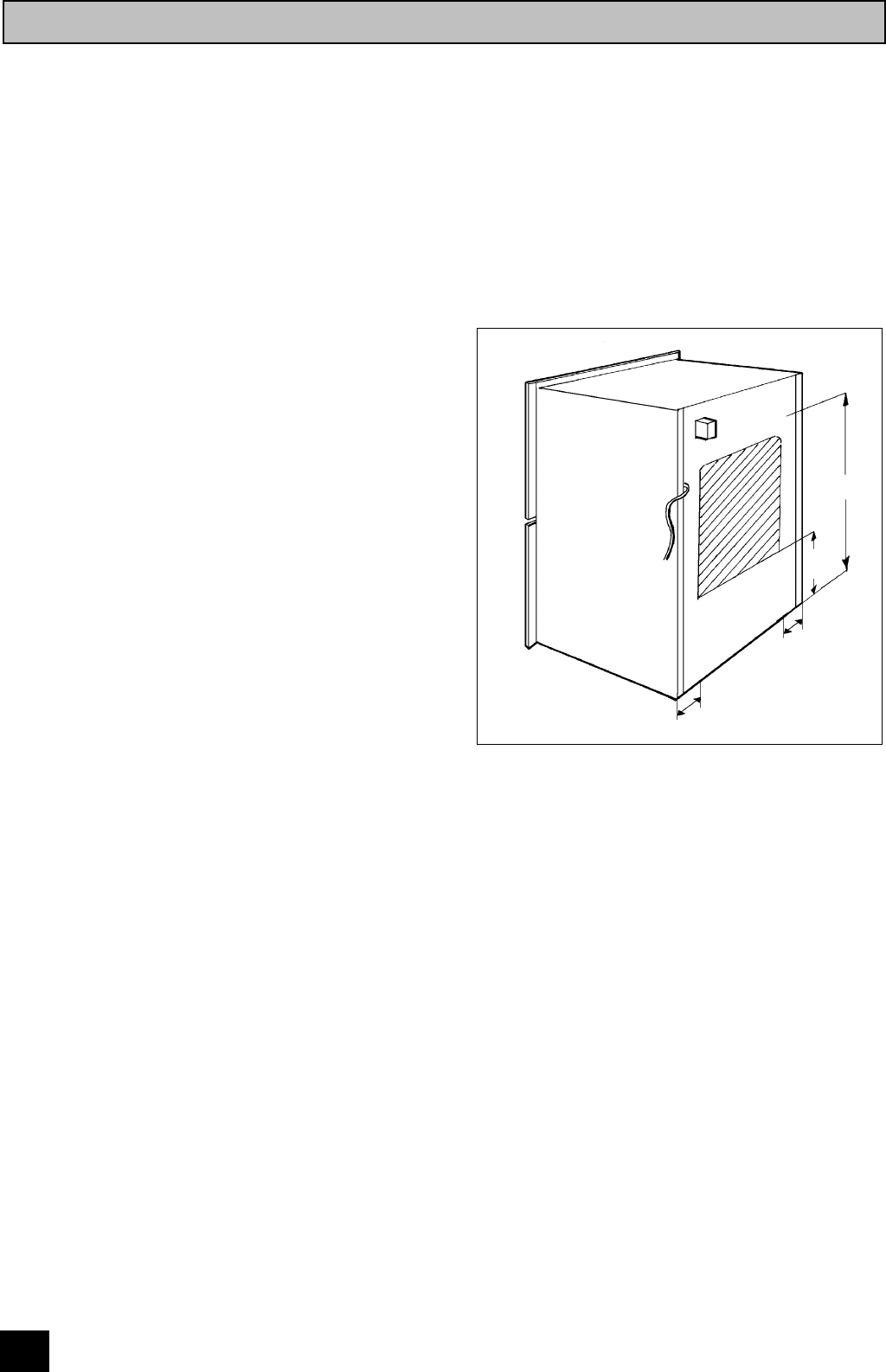

3 If the gas supply bayonet and wall fixing

bracket are to be located behind the

appliance it must be located in the shaded

area as indicated in Fig.8.

4 Connect flexible hose to the gas inlet supply

block see Fig.8. The hose should be long

enough to allow the appliance to be

withdrawn from the cabinet.

5 Position the appliance in front of the cabinet

and run the supply cable (See Connection

to Electricity Supply) through the cabinet

and connect to the junction box or socket.

Ensure that the supply is isolated at this

stage. Connect flexible hose to the bayonet

connector.

44

INSTALLATION INSTRUCTIONS

Fig.8

120

120

580

280