6

1.3.1 Reduced clearances using shielding

You may decrease the minimum clearances to combustible materials by installing heat radiation

shields between the walls or the ceiling and the stove. Those heat radiation shields must be installed

permanently, and must be made of a heat-resistant or heat-tolerant material. Consult the table below:

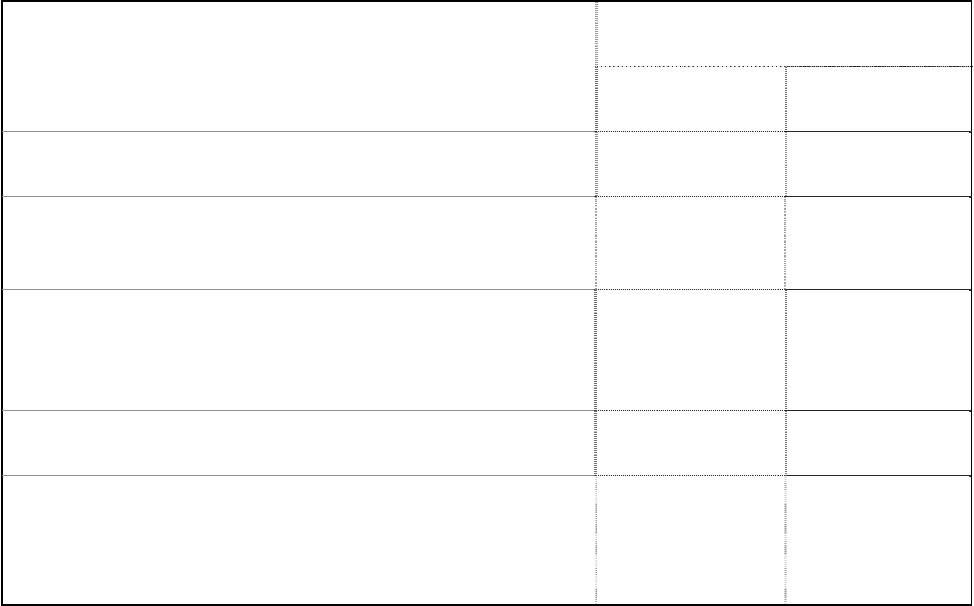

Reducing Clearances With

Shielding

TYPE OF PROTECTION

Sides and

Rear/Back

Top

Sheet metal, a minimum of 0,013" (0,33 mm) spaced out at

least 7/8" (21 mm) by non-combustible spacers.

67% 50%

Ceramic tiles, or an equivalent non-combustible material on

fire-proof supports spaced out at least 7/8" (21 mm) by non-

combustible spacers.

50% 33%

Ceramic tiles, or an equivalent non-combustible material on

fire-proof supports with a minimum of 0,013" (0,33 mm)

sheet metal backing spaced out at least 7/8" (21 mm) by non-

combustible spacers.

67% 50%

Brick spaced out at least 7/8" (21 mm) by non-combustible

spacers.

50% N/A

Brick with a minimum of 0,013" (0,33 mm) sheet metal

backing spaced out at least 7/8" (21 mm) by non-

combustible spacers.

67% N/A

Source: CSA Standard B365-1991, Table 4, Page 27

Convert specification to R-value:

k-factor is given with a required thickness (T) in inches: R=1/k x T

C-factor is given: R=1/C

Example:

If the floor protector is 4” brick with a C-factor of 1.25 over 1/8” mineral board with

a k factor of 0.29 the total R-value of the system is:

4” brick C=1.25, R=1/1.25=0.8

1/8” mineral board K=0.29, R=1/0.29 x 0.125=0.431

Total R = Rbrick + Rmineral = 0.8 + 0.431 = 1.231

Total R is greater than 1.0, the system is acceptable.