INSTALLATION INSTRUCTIONS

8

It is the responsibility of the installer to en-

sure the duct work will not collapse or bend

during and after installation. Dometic Corpo-

ration will not be liable for any structural dam-

age due to improperly insulated, sealed or

collapsed duct work.

CAUTION

Dometic Corporation will not be held liable

for roof structural or ceiling damage if the

duct work is not adequately wrapped in an

insulation blanket.

CAUTION

2.3.1 COOLING REQUIREMENTS

When determining the cooling requirements of each vehicle,

the following should be considered:

A. The size of the vehicle will determine the number of

air conditioning units that are required, or the need

to pre-wire for additional air conditioners depending

on the geographical location of use.

B. Amount of insulation in walls, floor and roof of the

vehicle.

C. Identify possible heat sources and plan accordingly:

1. Skylights - location should not be within 4 feet of

the air conditioner return system.

2. Skylights - should be tinted and double pane.

3. Roof vents should be a tinted type, and quan-

tity kept to minimum.

4. Increased use of slide-outs and/or glass square

footage will require tinting with additional

insulation in wall and ceiling cavities.

5. Calculation of heat producing appliances.

2.3.2 AIR DISTRIBUTION SYSTEM SIZING

Basement systems are designed exclusively with external

ductwork for the cold air discharge. There are not provi-

sions for an electric heater to be installed as part of the

unit. The central furnace will supply heating of the

vehicle, if installed.

The condenser section must be installed so as to have direct

access to the outside ambient. Removal of the heated

condenser air is critical for proper operation.

The installer of this air conditioner must design the air

distribution system for his particular application by following

the guidelines specified within this application manual and

unit installation instructions. Several specific requirements

MUST BE met for the air conditioner to operate correctly:

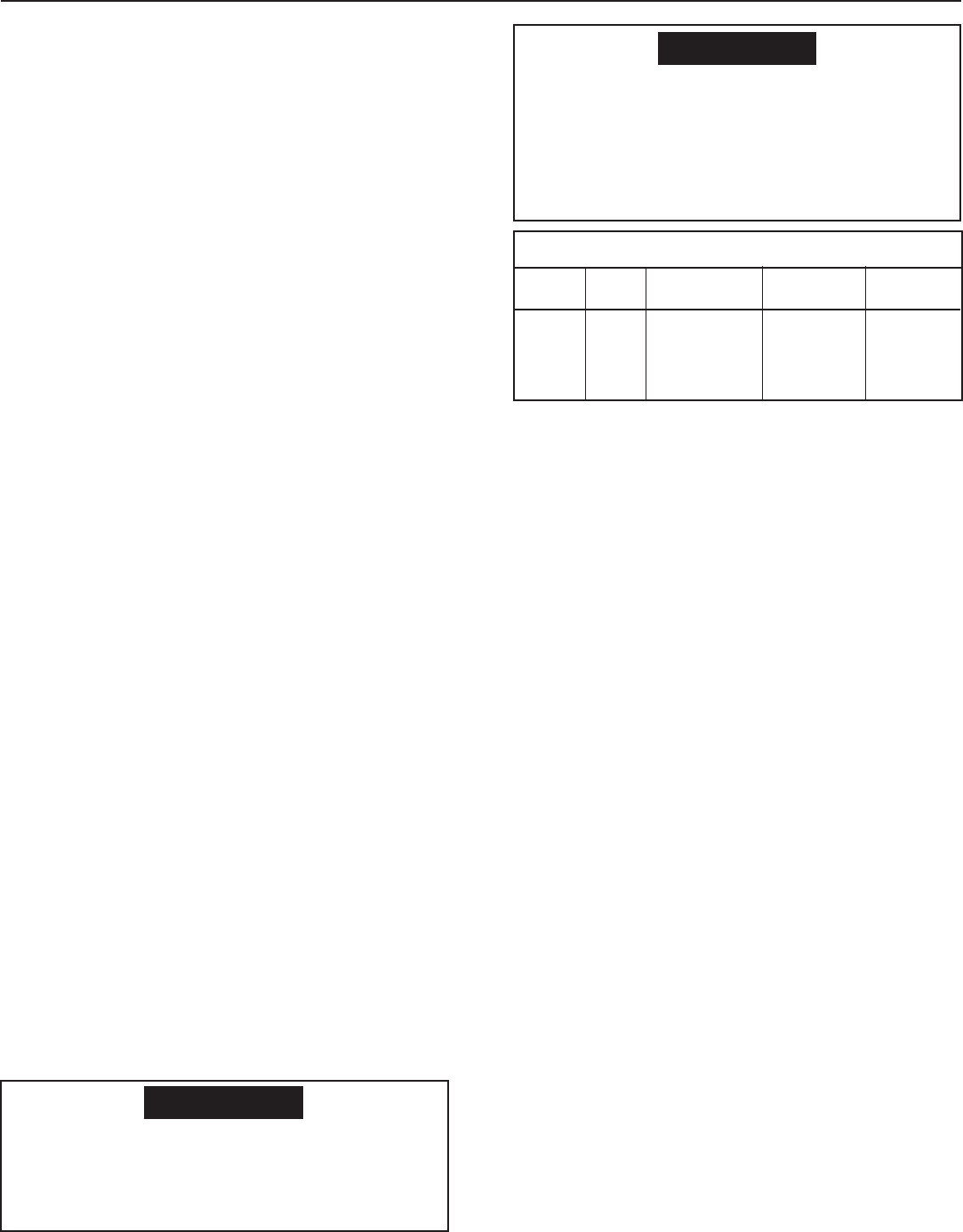

1. Unit Total Static Pressure See Figure 2.10.

2. Duct Area Requirement. See Figure 2.10.

3. Return air to the system must be filtered to prevent

dirt accumulation on the evaporator cooling surface.

4. Return air opening must be within minimums speci-

fied in the system installation instructions. This

figure must include the filter material selected.

5. Since duct work is located within a cavity, it is

necessary that all duct work must be wrapped with

a minimum R7 insulating blanket with a vapor

barrier. This will help prevent heat gain within the

duct and possible condensation.

2.3.3 AIR DISTRIBUTION DUCT PREPARATION

Depending on the distribution configuration, ensure that the

air entry points have the minimum square inches required for

the series of system installed. See Figure 3.4 for permissible

duct layout. Duct elbows and/or restrictions must be kept to

a minimum. The duct must be pre-built within the structure

and sealed along its entire length. If joints or bends leak

conditioned air within the cavity, condensation will form.

When the duct is installed within the structure, care must be

taken to insure that the duct will not collapse or bend during

or after installation of the system to the vehicle.

2.3.4 LOCATION OF DISTRIBUTION DUCT

The vehicle itself and the placement of interior components

will dictate the location of the duct. One must be sure that the

registers will not fall near the thermostat or the return filters.

The placement must be such that the air distribution from the

registers will provide the best possible movement within the

living area. Calculations should be made as to the strength

of the cavity, to insure structural integrity if notched for

location of the duct runs.

2.3.5 RETURN REQUIREMENTS

The return air system must be considered when layout of the

duct system is in process. This should be located as near to

the system as possible to insure adequate return back to the

evaporator coil.

2.4 HI-POT REQUIREMENTS

Each system that is built by Dometic is completely checked

electrically and hi-pot tested on our production line. Addi-

tional hi-pot testing of the system must not be done.

Disconnect the system from the power circuit prior to any

vehicle high potential test operations.

System Duct Condenser Evap. Static

P/N Size Inlet Req. Inlet Req. Press

39626 3x15" 648 in

2

135 in

2

0.40 - 1.20

39726 min.

5x16"

max.

FIG. 2.10