4

3

PURPOSE OF HEAT PUMP

SCOPE OF DELIVERY

PURPOSE OF THE HEAT

PUMP

2.1 Application

The brine-to-water heat pump is designed for use

in existing or newly built heating systems. Brine is

used as the heat carrier in the heat source system.

Ground coils, ground collectors or similar systems

can be used as the heat source.

2.2 Principle of Operation

The heat generated by the sun, wind and rain is

stored in the ground. This heat stored in the ground

is collected at low temperature by the brine circulating

in the ground collector, ground coil or similar device.

A circulating pump then conveys the warmed brine

to the evaporator of the heat pump. There, the heat

is given off to the refrigerant in the refrigeration cycle.

When so doing, the brine cools so that it can again

take up heat energy in the brine circuit.

The refrigerant, however, is drawn in by the electrically

driven compressor, is compressed and "pumped"

to a higher temperature level. The electrical power

needed to run the compressor is not lost in this

process, but most of the generated heat is trans-

ferred to the refrigerant as well.

Subsequently, the refrigerant is passed through the

condenser where it transfers its heat energy to the

heating water. Based on the thermostat setting, the

heating water is thus heated to up to 55 °C.

2

SCOPE OF DELIVERY

3.1 Baseline Unit

The baseline unit consists of a heat pump, ready

for connection, for indoor installation, complete with

sheet metal cabinet, control box and integrated

controller. The refrigeration cycle contains the

refrigerant R404A. Refrigerant R404A is CFC-free,

non-ozone depleting and non-combustible.

All components required for the operation of the heat

pump are located in the control box. A sensor for

the external wall temperature including mounting

hardware as well as a strainer are supplied with

the heat pump. The voltage supply for the load

and control current must be provided by the

customer.

The control wire of the brine pump (to be provided

by the customer) is to be connected to the control

box. When so doing, a motor protecting device is

to be installed, if required.

The collector loops including the brine manifold

must be provided by the customer.

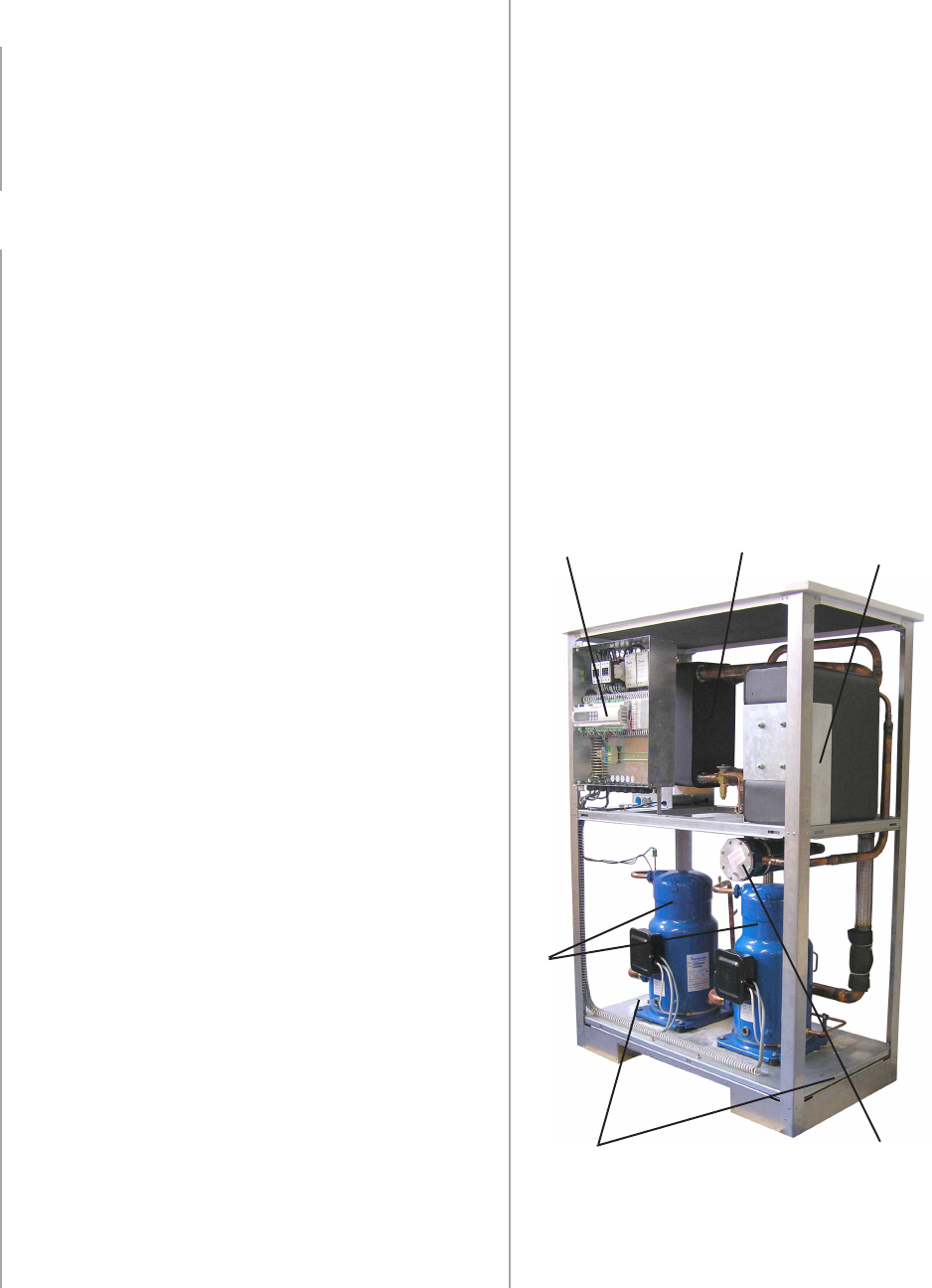

123

4

56

1) Control 4) Compressor

2) Evaporator 5) Transport securing

devices

3) Condenser 6) Filter drier