7

MOUNTING

7.3 Connection on Heat Source

Side

The following procedure must be observed when

making the connection:

Connect the brine line to the flow and return pipe

of the heat pump.

The supplied strainer must be fitted

in the heat source inlet of the heat pump in order

to protect the evaporator against the ingress

of impurities.

In addition, a powerful vent must be installed at

the highest point of the heat source system. The

hydraulic plumbing diagram must be observed

here.

The brine liquid must be produced prior to

charging the system. The brine concentration

must be at least 25 %. Freeze protection down to

-14°C can thus be ensured.

Only antifreeze products on the basis of mono-

ethylene glycol or propylene glycol may be used.

The heat source system must be vented (de-

aerated) and checked for leaks.

The brine solution must contain at

least 25 % of an antifreeze and corrosion

protection agent on a monoethylene glycol or

propylene glycol basis.

7.4 Electrical Connection

The following electrical connections must be

established on the heat pump:

- Connection of the control wire to terminals X1:

L/N/PE in the control box of the heat pump.

- Connection of the load wire to terminals X5:

L1/L2/L3/PE in the control box of the heat pump.

- The control of the brine pump is effected via the

controller N1/J12/N03/N + PE (max. 200 W), or

a pump contactor connected to these terminals

(without PE). If a motor protective switch is used,

the auxiliary contact (NC contact) needs to be

connected to N1/J5/ID5 and X2, instead of the

wire jumper which must be removed.

All electrical components required for the operation

of the heat pump are located in the control box.

CAUTION!

For more detailed instructions concerning the

connection and functioning of the heat pump

controller (e.g. the supplied external wall sensor)

please refer to the enclosed operating manual of

the controller.

An all-pole disconnecting device with a contact gap

of at least 3 mm (e.g. utility company disable contac-

tor or power contactor) as well as a 3-pole circuit

breaker with simultaneous tripping of all external

conductors must be provided . The required cross-

sectional area of the conductors is to be selected

according to the power consumption of the heat

pump, the technical connection requirements of the

relevant utility company and all applicable regula-

tions. Power consumption data of the heat pump is

provided in the product literature and on the

nameplate. The terminals are designed for a max.

conductor cross-section of 35 mm˝.

The clockwise phase sequence must

be observed when connecting the load lines (the

heat pump will deliver no output and will be very

noisy when the phase sequence is incorrect).

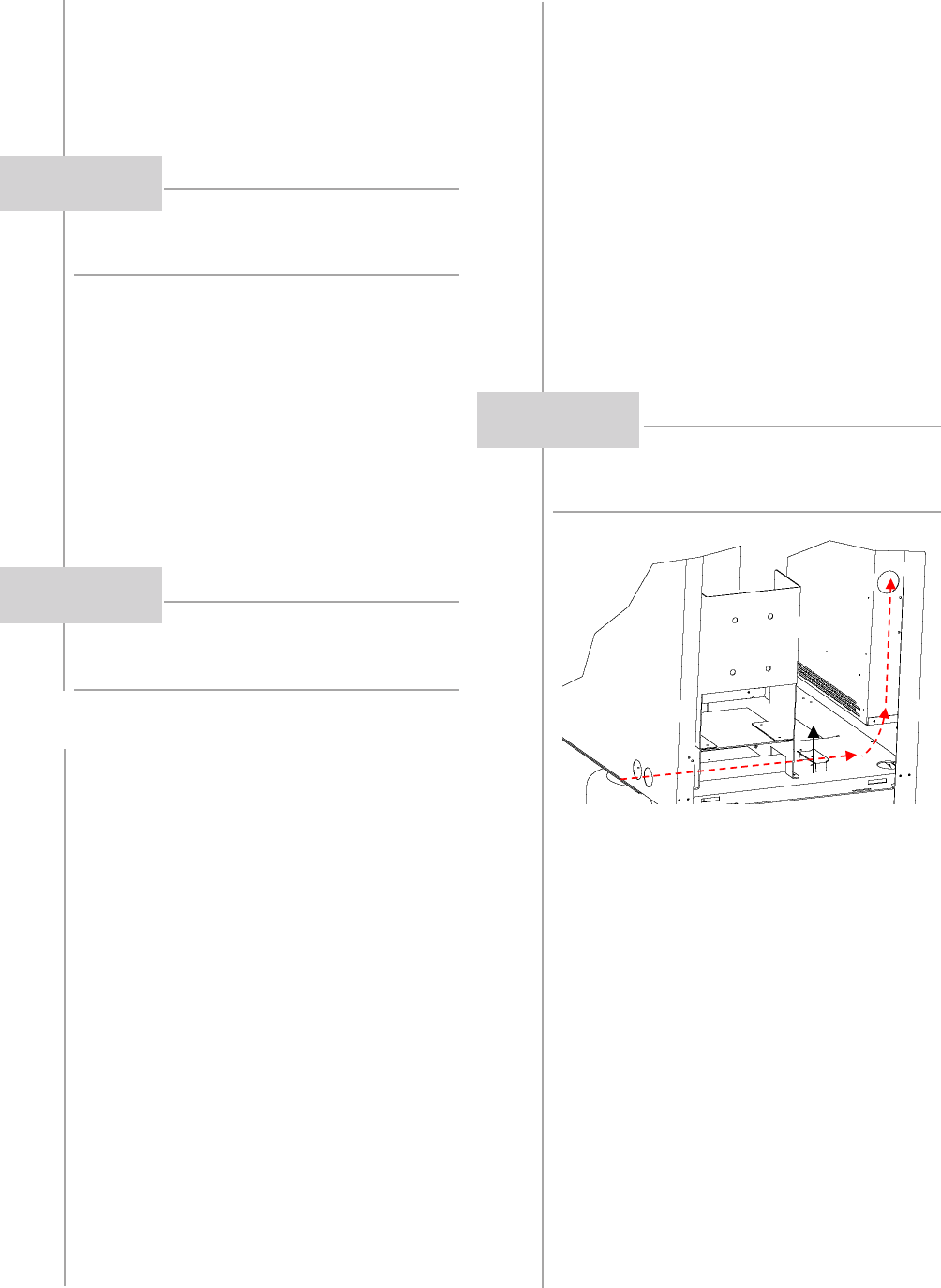

The power cable must be run through the guide

tubes, inserted into the side of the control box and

secured by means of the strain relief.

CAUTION!

CAUTION!