www.desatech.com

56131-F26

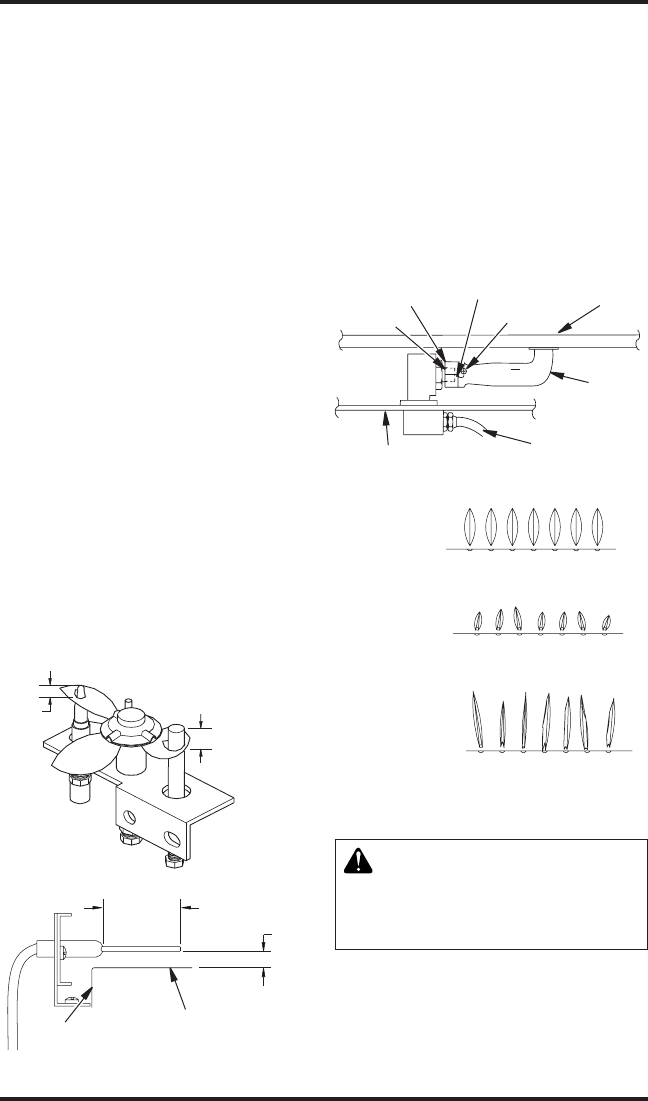

Figure 52 - Correct Pilot Flame Pattern

1/8"

(0.3cm)

3/8" - 1/2"

(.95cm-1.3cm)

1/2"

(12.7 mm)

3/4"

(19 mm)

Edge of Burner

Top of

Burner

Figure 53 - Correct Ignitor Location

(Side View)

bURNER FLAME

ADjUSTMENT

The air shutter, located at the base of the main

burner (see Figure 54), has been factory preset

to the proper air-to-gas ratio which results in an

even, clean burning ame across the burner (see

Figure 55). If readjustment is necessary, you can

restore the proper air-to-gas ratio by loosening the

air shutter screw and rotating the air shutter until

the proper ame setting is achieved (the shutter's

normal setting is fully open. Do not forget to

retighten the air shutter screw.

Figure 55 - Burner Flame Patterns

Figure 54 - Air Shutter Adjustment

Air Shutter

Air

Opening

Burner

Venturi

Tube

Burner Gas Line

CORRECT

INCORRECT

CLOSE

SHUTTER

INCORRECT

OPEN SHUTTER

Short, Sharp, Blowing Flame

Long, Blue Flame with

Yellow Tips

Long, Uneven, Yellow Flame

Firebox Bottom

Adjustment

Screw

Orice

-

1. Remove top and bottom louvers and screen as-

sembly. Undo 4 latches and open glass door.

2. Carefully remove the log set intact and set

aside (see Figure 56, page 27).

3. Remove the 2 screws holding burner to hearth

pan.

DECORATIVE FACING

Any noncombustible material may be used for

facing (glass, tile, brick, etc.) as long as the proper

clearances are observed (see Clearances, page 6).

IMPORTANT: Louvered openings must not be ob-

structed, and upper and lower panels must remain

removable for servicing. Use only heat-resistant,

noncombustible mortar or adhesive when securing

facing material.

Note: Combustible material, such as wood, that

has been reproofed is not considered noncom-

bustible.

PILOT/ELECTRODE

ASSEMbLy ADjUSTMENT

The pilot assembly is factory preset for the proper

ame height. Alteration to these settings may have

occurred during shipping and handling. If this is the

case, some minor adjustment may be necessary and

should be done by a qualied technician. To access

the pilot assembly, the glass door must be opened.

The proper settings for the thermopile height should

be at a distance of 3/8" to 1/2" from the pilot ame

as shown in Figure 52.

The electrode is installed at the factory for proper

positioning. However, alterations to the position

may have occurred due to shipping and handling.

These settings may need adjustment and must be

done by a qualied technician. The correct position

and height is as shown in Figure 53.

INSTALLATION

Continued