18

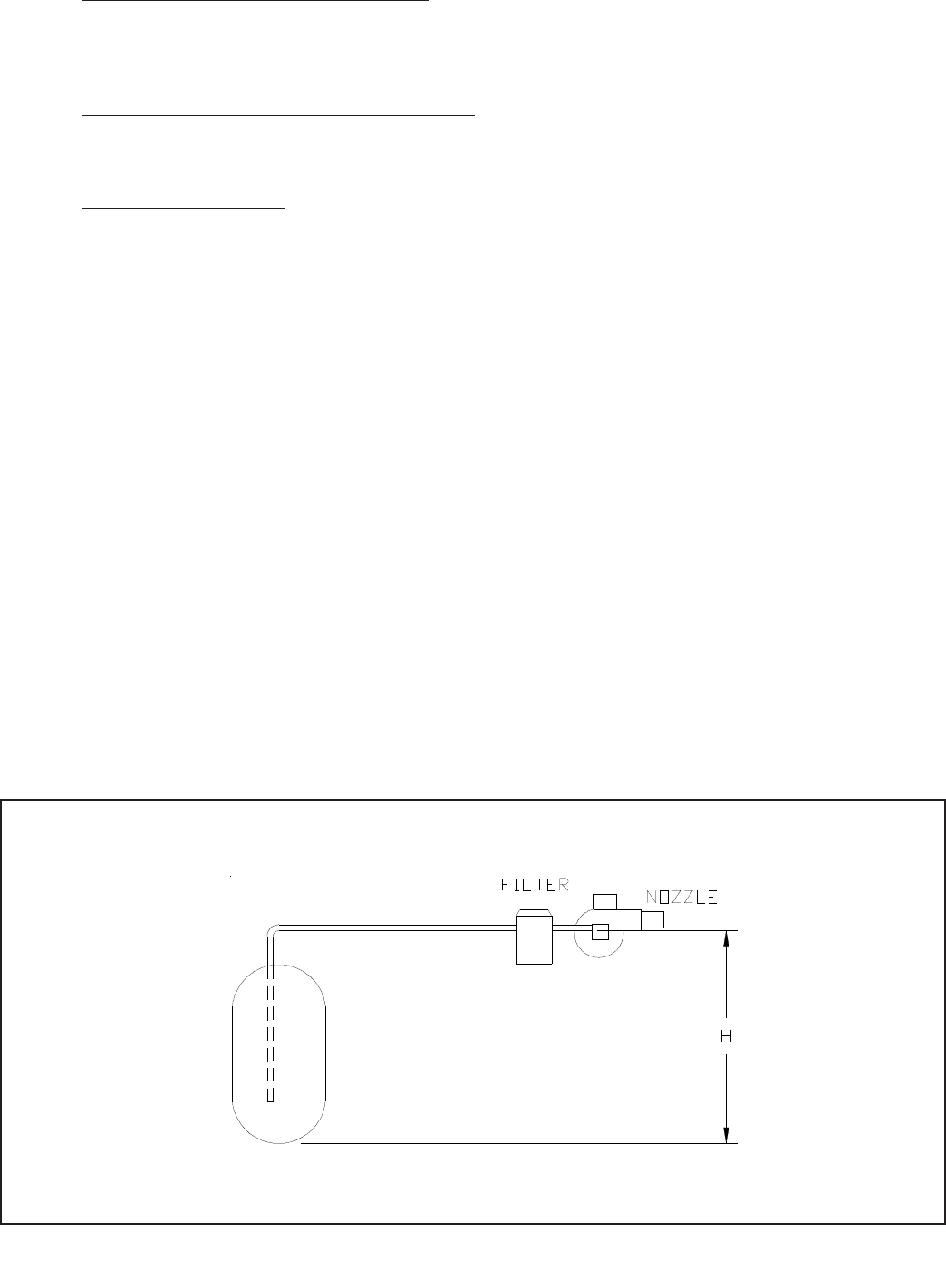

FIGURE 16: ONE-PIPE LIFT SYSTEM

b)

ONE-PIPE LIFT SYSTEM (not recommended) - Used when a fuel oil storage tank is located below an oil burner

fuel pump. See Figure 16. The vertical distance from bottom of the tank to center line of the pump (Dimension ‘H’)

must not exceed that shown in the pump manufacturer’s instructions. Although all oil piping systems must be airtight,

one-pipe lift systems are particularly susceptible to nuisance lockout problems if the suction line is not completely

airtight. A two-pipe lift system is therefore recommended over a one-pipe lift system.

c)

TWO-PIPE GRAVITY SYSTEM (not recommended) - Used when a fuel oil storage tank is located above an oil

burner fuel pump. See Figure 17. A vertical distance from top of the tank to center line of the pump (Dimension ‘H’)

over 8 feet will result in a pump inlet pressure in excess of the 3-psi limit in NFPA-31. This type of system should

be converted to a one-pipe gravity system, as doing so will result in lower inlet line flow and longer filter life.

d) TWO-PIPE LIFT SYSTEM - used when a fuel oil storage tank is located below an oil burner fuel pump suction port.

See Figure 18. The vertical distance from bottom of the tank to center line of the pump (Dimension ‘H’) must not

exceed that shown in the pump manufacturer’s instructions. Distance ‘H’ allowed is reduced by the number of

fittings, filters and valves installed in the line.

Once the type of system has been selected, observe the following:

1) Fuel line piping must be airtight. Do not use compression type fittings for tubing connections in fuel line piping. Use

only listed flare type fittings. Cast iron threaded fittings shall not be used for wrought iron or steel piping connections.

2) Piping shall be substantially supported and protected against physical damage and corrosion where required.

3) Refer to supplied oil pump instruction manual for proper connections. On one-pipe systems, ensure that the fuel pump

return port plug is tightened securely.

4) Some fuel pumps, such as the Suntec A and B series, are supplied with a loose bypass plug which must be installed on

two-pipe systems. If such a plug is supplied, install it as shown in the pump manufacturer’s instructions. Do not install

this bypass plug on one-pipe systems as pump seal damage will result.

5) Do not use check valves, especially on gravity feed systems.

6) Do not use Teflon tape for threaded connections. Use a listed non-hardening thread sealant instead.

7) Attach required piping between burner fuel pump and fuel oil storage tank. Install one fuel shut-off valve near the storage

tank and second fuel shut-off valve near the oil burner fuel pump. Use heavy wall copper tubing in a continuous run. On

two-pipe systems, the return line should terminate 3” - 4” above suction line depth within the storage tank. Refer to the

pump manufacturer’s instructions for tube sizing information.

8) All systems require an oil filter. On TWZ065 and TWZ075 boilers, the use of a Garber cartridge type filter is

recommended.

9) Use only #2 Fuel Oil with physical and chemical characteristics meeting the requirements of ASTM D-396.

17