24

6) Use locking bands provided to join adjacent sections of non-cuttable pipe as well as fittings. The male end of the terminal

section and other cuttable sections must be held to the female end of the adjoining pipe with at least three #10 x 1/2” sheet

metal screws. Drill a 1/8 hole through both outer pipes to start this screw. Use a drill stop or other means to ensure that

the drill bit does not penetrate more than 3/8” into the outer pipe. Do not use a sheet metal screw longer than 1/2”.

7) The only straight pipe that can be cut is the terminal section, the 19-1/2” section (Crown PN 230506) and the 80/125

straight riser (PN230515). To cut this pipe:

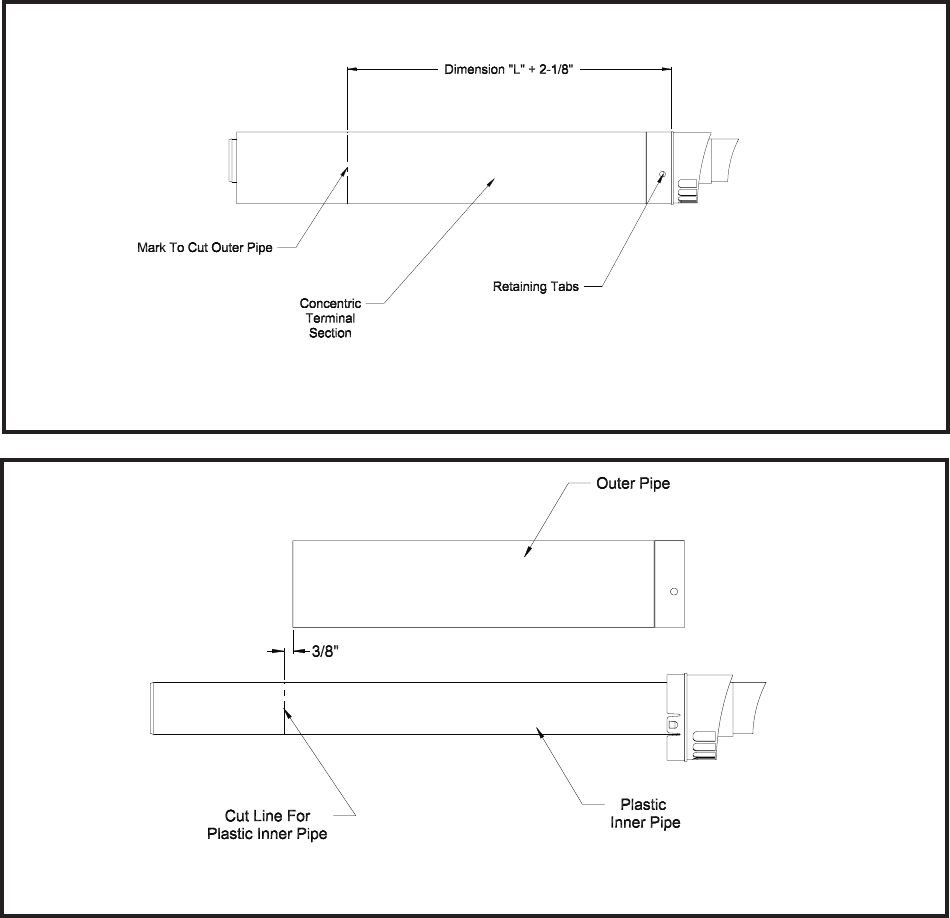

a) Cut pipe from the male end. After marking the desired length of the outer pipe, remove the plastic inner pipe by pulling

it out from the female end.

b) Cut the outer pipe only at the point marked in Step (b) using aviation shears, a hacksaw, or an abrasive wheel cutter. Be

careful to cut the pipe square. De burr the cut end with a file or emery cloth.

c) Cut the plastic inner pipe so that it will protrude 3/8” beyond the outer pipe when reinstalled in the outer pipe. Use a

fine tooth hacksaw or a PVC saw to cut the plastic pipe and be careful to cut the pipe square. De burr the cut edge of the

plastic pipe with a file, razor blade, or fine sandpaper.

d) Reinstall the inner pipe.

8) Install the terminal as outlined in Step (4) above. Dimension “L” described in Step 4 is the distance from the exterior sur-

face of the wall to the end of the last piece of pipe inside the building.

FIGURE 7.22: CUTTING OUTER PIPE

FIGURE 7.23: CUTTING INNER PIPE