Page 30 Clarke

®

BEXT

®

-100, 100H 150H, 300HV Operator's Manual

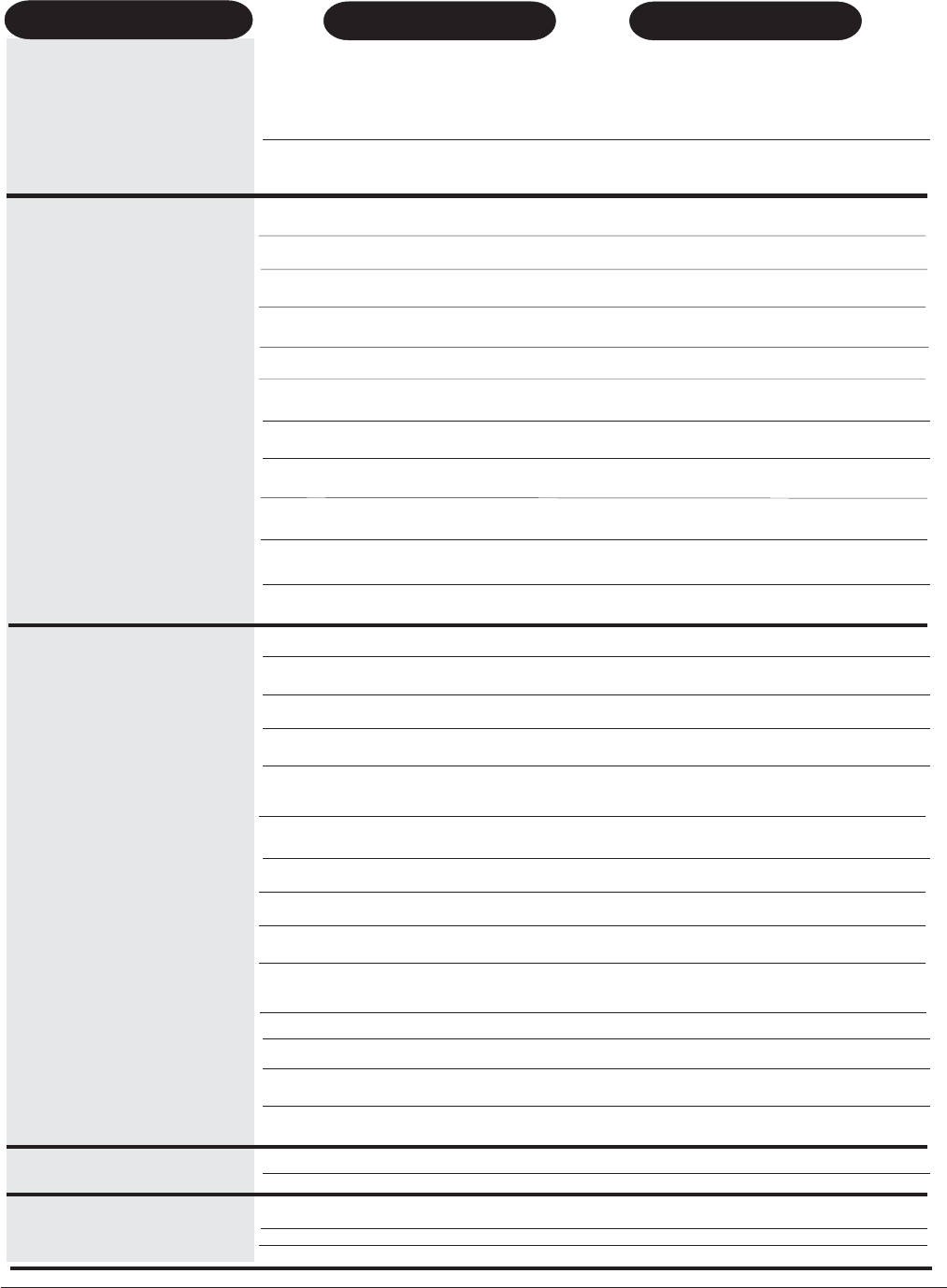

HOW TO CORRECT PROBLEMS IN THE MACHINE

ActionCause

Problem

1. Make sure the machine is connected to the

correct frequency and voltage, and all connec-

tions are tight.

Make sure the plug is in the electrical outlet.

2. Contact an authorized service person to replace

the cord.

1. Put the switch for the vacuum in the "I" position.

2. Contact an authorized service person.

3. Contact an authorized service person.

4. Remove the obstruction.

5. Remove the liquid from the tank.

6. Contact an authorized service person to re-

place gasket.

7. Contact an authorized service person.

8. Replace the dome.

9. Replace the motor brushes.

10. Close drain gate.

11.Contact an authorized service person.

1. Put the switch in the "I" position.

2. Contact an authorized service person.

3. Contact an authorized service person.

4. Contact an authorized service person.

5. Contact an authorized service person.

6. Straighten the hose. Replace if damaged.

7. Contact an authorized service person.

8. Contact an authorized service person.

9. Contact an authorized service person.

10.Contact an authorized service person.

11.Contact an authorized service person.

12.Fill the solution tank.

13.Clean the screen.

14.Contact an authorized service person.

1. Contact an authorized service person.

1. Clean the float. Replace if damaged.

2. Put defoamer in the solution. Order P/N 398420.

3. Clean the gasket. Replace if damaged.

1. The machine has no power.

2. The power cord is damaged.

1. The vac motor does not run.

2. The vac motor switch is defective.

3. There is a loose motor connection.

4. There is an obstruction in the vacuum

hose.

5. The recovery tank is full.

6. The dome gasket is worn or damaged.

7. The internal vac hose is damaged

or stopped.

8. The dome is damaged

9. The motor brushes are worn.

10. Drain gate is open.

11.Seals are damaged.

1. The switch is in the "OFF" position.

2. The pressure switch is damaged.

3. The pump motor will not run.

4. The pump motor brushes are worn.

5. The quick disconnect fitting is dirty

or stopped.

6. The solution hose is bent.

7. The pump is worn.

8. The pump switch is defective.

9. The pump connections are loose.

10.The pump intake and oulet valves are

worn.

11.The thermol protector is open.

12.The solution tank is empty.

13.The intake screen is dirty.

14.The rectifier in the pump motor is bad.

1. The tank is damaged.

1. The float is dirty or damaged.

2. There is too much foam.

3. The float gasket is dirty or damaged.

The machine will not run.

There is no suction.

There is no pressure.

The solution tank leaks.

The recovery tank overflows.