OPTIONAL EQUIPMENT

Temperature Indicators (Suffix “D”)

(FXTH Heater Assembly and Control Center will have

suffix "D" e.g. FXTH-11206D, WCG15-213D)

MOUNTING

Temperature indicators are balanced for accurate reading in a normal

vertical position unless specified otherwise. All pyrometers labeled

"shielded meter" may be used in any type of panel with little or no

effect on calibration. Those labeled "non-magnetic" must be used

only on aluminum, plastic, wood or other non-magnetic panels. They

will read low if mounted in a steel panel. Pyrometers which are

labeled "magnetic" are intended for installation on steel panels. A

steel compensating ring is normally supplied where panel material is

not specified. Discard the ring when mounting on a steel panel. If the

pyrometer is used on a non-magnetic panel, the steel ring must be

used. Be sure the slit in the ring is at the top of the meter barrel and

the ring is pushed as far forward as it will go.

THERMOCOUPLE SELECTION AND CALIBRATION

Each pyrometer is marked on the dial with the type of thermocouple

and the total external resistance for which it is calibrated. Use of any

other type of thermocouple or one with a higher resistance than

marked will result in incorrect readings. (Type J thermocouples are

normally used.) All standard pyrometers are calibrated for 10 ohms

external thermocouple resistance and are provided with a 10 ohm cal-

ibrating resistor bobbin. (Non-standard pyrometers are usually cali-

brated for the specific external resistance ordered and no resistor bob-

bin is supplied.) This resistor bobbin must be adjusted so the total

resistance of the thermocouple and the bobbin add up to 10 ohms in

order to maintain calibration accuracy. Therefore, for a 5 foot, 20

gauge, iron-constantan thermocouple, the resistance of the thermo-

couple would be approximately 1.75 ohms and this resistance must be

subtracted from the calibrating bobbin. Each turn of the wire on the

resistor bobbin represents 0.5 ohms and for this example, 3-1/2 turns

would be removed. The total resistance of the thermocouple plus the

resistor bobbin would then add up to 10 ohms. For other values of

thermocouple resistance, simply remove more or less turns to adjust

for the total value of external resistance marked on the pyrometer

dial.

It is very important the resistor wire be properly soldered after

adjusting.

NOTE: When Thermocouples with external resistance higher than 10

ohms will be used, a special pyrometer will be required. The use of

other than thermocouple wire for leads or extensions may result in

improper ambient compensation.

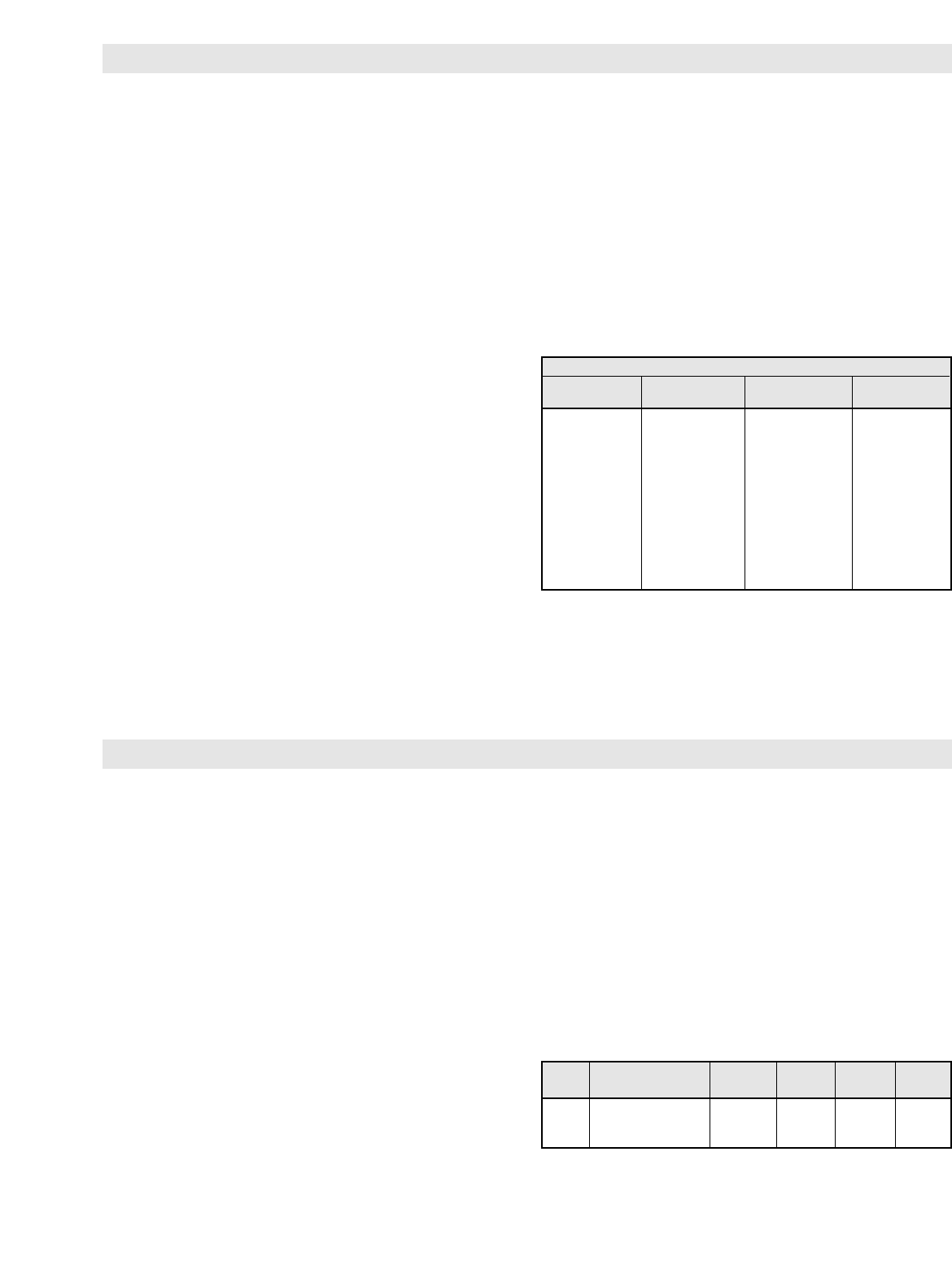

ABBREVIATED TABLE OF THERMOCOUPLE RESISTANCE

The table lists the resistance in ohms per pair-foot for various types

of commonly used thermocouples for a number of different gauges of

wire. By using this table, it is necessary only to measure the length of

the thermocouple, knowing the type and gauge, to determine its

approximate resistance. (Actual measurement of the thermocouple

resistance is preferred to using the table.)

8 .0215 .0184 .0365

10 .0341 .0293 .0580

12 .0542 .0466 .0922

14 .0863 .0741 .1470

16 .1370 .1180 .2330

18 .2180 .1870 .3710

20 .3570 .2980 .5900

22 .5510 .4690 .9370

24 .8770 .7530 1.490

26 1.390 1.200 2.370

28 2:220 1.910 3.770

30 3.520 3.030 5.980

Ohms Per Pair - Foot

Iron/Constantan Copper/Constantan Chromel/Alumel

Gauge B & S (Type J) (Type T) (Type K)

CHROMALOX TYPE TMC 7-DAY TIMER

TMC 7-day Calendar, Electric Dial Timer is used to provide auto-

matic start-up/off-on control of large tank heaters or could be set up

for non-peak operation. Standard features: 7-day calendar dial per-

mits different on/off schedules on different days of week. 2 to 14

replaceable trippers for up to 4 on/off operations per day, up to 28

on/off operations per week. 3 hour minimum on or off time; 21 hour

maximum on or off time. Independent 4-pole design allows SPST,

DPST, SPDT, switching. Manual on/off lever transfers switch opera-

tion without disturbing daily or weekly preset schedule. Heavy duty

synchronous motor suitable for operation between -40°F and +140°F.

Switch slider bar assures positive switching. Heavy duty terminals

accommodate up to AWG No.8 wire.

OPERATION

“Off” Setting - de-energizes the entire zone control circuit, thus de-

energizing all heating-cooling equipment in the zone. This setting can

be used for extended summer shutdowns, etc.

“Automatic” Setting - allows the Day-Night Clock Panel to cycle

the control system according to the program clock dial tripper set-

tings.

To Set Trippers - Refer to picture for typical setup of a Seven Day

Program. Two trippers must be used for each day; an “A” tripper for

switching from “Night Setback” to “Day Operation” and a “B” trip-

per for switching from “Day Operation” to “Night Setback”.

CAUTION: To set the correct day and time at beginning of initial

start-up, ROTATE THE PROGRAM CLOCK DIAL CLOCKWISE

ONLY. DO NOT ATTEMPT TO TURN POINTER!

Adjusting and Maintenance of Time Switch:

1. Periodically check trippers to insure that they are tightly fastened

to Program Clock dial. CAUTION: TIGHTEN TRIPPERS WITH

FINGERS ONLY!

2. Rotate Program Clock dial CLOCKWISE one hour in Spring to

adjust for daylight saving time (in areas where required). In Fall,

carefully rotate clock dial CLOCKWISE approximately one full

turn to reset at correct day and time for standard time. Check all

trippers to insure they have not moved during rotation.

3. The Program Clock motor is permanently lubricated. Lubrication

of other parts is not required.

4. The Program Clock switch contacts are factory set and need no

field adjustment.

4 Pole

TMC71 311-057070-001 Seven Day 120 2 N.O. 40

2 N.C.

Renewal Volts

Model Part No. Operation 60 Hz Switch Amps

7