Chromalox

®

(Supersedes PE414-2)

PE414-3

NWH

161-304777-001

MAY, 2007

4

RENEWAL PARTS IDENTIFICATION

Installation, Operation

and

Circulation

Heaters for Oil or Water Heating

© 2010 Chromalox, Inc.

Specifications – Table A

GENERAL

READ ALL INSTRUCTIONS BEFORE USE

FIRE/EXPLOSION HAZARD. Ordinary location

heaters (designated E1) are not intended for use in

hazardous atmospheres where flammable vapors,

gases, liquids or other combustible atmospheres are

present as defined in the National Electrical Code.

Failure to comply can result in personal injury or

property damage.

This design has the versatility of field adjustments of voltage

kW through various wiring combinations.

The NWHSRG model is a general purpose water circulation

heater intended for indoor use. E2 designs have a Moisture

Resistant/Explosion Resistant enclosure. Designs are up to 40kW

- DO NOT USE THE NWHSRG MODEL FOR OIL.

The NWHOSR model is a general-purpose regular and fuel oil

solution circulation heater intended for use indoors. E2 designs

have a Moisture Resistant/Explosion Resistant enclosure. Designs

are up to 10kW - DO NOT USE THE NWHOSR MODEL FOR

WATER. Ensure the wiring guide for oil is used for the correct

wiring diagram.

Both the NWHSRG and NWHOSR use six INCOLOY

®

sheath

elements welded to a steel 2.5” screw plug. The vessel is cast iron

and is surrounded by 1.5” insulation and a sheet metal jacket. For

water applications, the vessel has a galvanized coating. A J-type

thermocouple in a thermowell is standard. These

versaTHERM

TM

heaters

are designed for 150 psig max. at 35°F min. to 300°F max.

IMPORTANT: It is the responsibility of the purchaser of

the heater to make the ultimate choice of sheath

material based upon his knowledge of the chemical

composition of the corrosive solution, character of the

materials entering the solution, and controls which he

maintains on the process.

ELECTRIC SHOCK HAZARD. Disconnect all power

before installing or servicing heater. Failure to do

so could result in personal injury or property dam-

age. Heater must be installed or serviced by a

qualified person in accordance with the National

Electrical Code. NFPA 70.

The system designer is responsible for the safety

of this equipment and should install adequate

back-up controls and safety devices with their

electric heating equipment. Where the conse-

quences of failure could result in personal injury or

property damage, back-up controls are essential.

If foreign material is to be carried by the liquid flow, install

suitable filters in the inlet pipe to the heater.

Ensure the temperature/pressure is controlled below the vapor

point of the liquid at all times and is within the temperature/pres-

sure ratings for this heater.

Heating elements must be completely immersed in liquid when

energized.

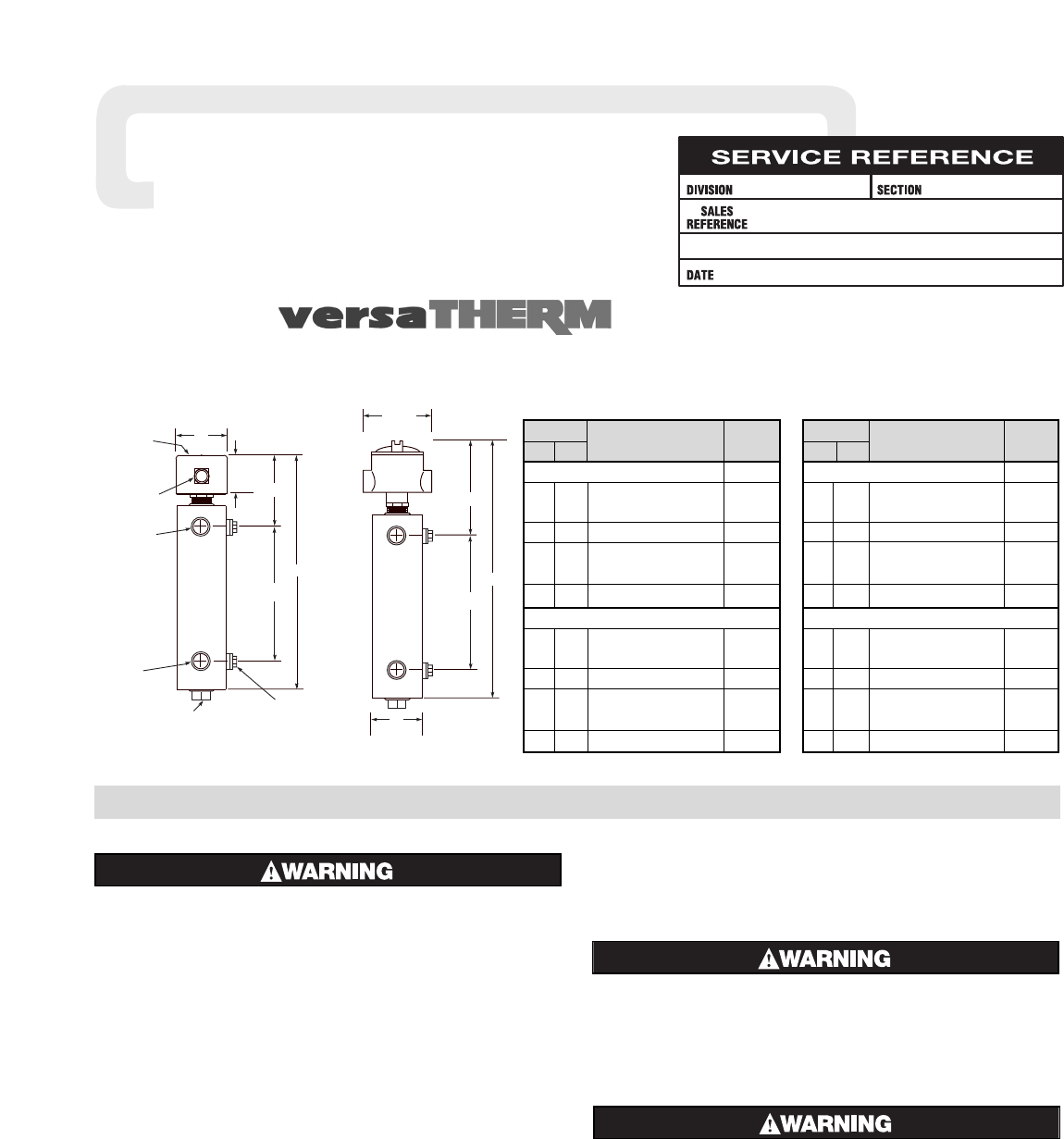

Dim. (In.)

A B Model PCN

Cast Iron Body / Oil .5 to 10 kW

29 19 NWHOSR-06-04P5-E1 100108

29 19 NWHOSR-06-04P5-E1 100116

41 30

3

/4 NWHOSR-06-005P-E1 100124

29 19 NWHOSR-06-006P-E1 100132

29 19 NWHOSR-06-006P-E1 100140

41 30

3

/4 NWHOSR-06-010P-E1 100159

Galvanized Body / Water .5 to 40 kW

29 19 NWHSRG-06-018P-E1 100010

29 19 NWHSRG-06-018P-E1 100028

41 30

3

/4 NWHSRG-06-020P-E1 100036

29 19 NWHSRG-06-024P-E1 100044

29 19 NWHSRG-06-024P-E1 100079

41 30

3

/4 NWHSRG-06-040P-E1 100095

A

B

6"

Rotatable

Terminal

Cover

1" Conduit

Opening

Outlet

1" FNPT

Inlet

1" FNPT

1" FNPT Pipe Plug

(or Inlet)

8 / "

1

2

4"

2 Mtg. Lugs

/ "-13 x / " Deep

1

1

2

2

Specifications – Table B

Dim. (In.)

A B Model PCN

Cast Iron Body / Oil .5 to 10 kW

32 19 NWHOSR-06-04P5-E2 100255

32 19 NWHOSR-06-04P5-E2 100263

44 30

3

/4 NWHOSR-06-005P-E2 100271

32 19 NWHOSR-06-006P-E2 100280

32 19 NWHOSR-06-006P-E2 100298

44 30

3

/4 NWHOSR-06-010P-E2 100300

Galvanized Body / Water .5 to 40 kW

32 19 NWHSRG-06-018P-E2 100327

32 19 NWHSRG-06-018P-E2 100343

44 30

3

/4 NWHSRG-06-020P-E2 100351

32 19 NWHSRG-06-024P-E2 100360

32 19 NWHSRG-06-024P-E2 100378

44 30

3

/4 NWHSRG-06-040P-E2 100386

Dimensions (Inches)

A

B

11"

7-7/8"

6"

E1

E2

TM