WIRING

WARNING:

Hazard of Electric Shock. Any installation

involving electric heaters must be effectively grounded

in accordance with the National Electrical Code to elim-

inate shock hazard.

1. Electrical wiring to heater must be installed in accordance

with the National Electrical Code and local electric codes by a

qualified person. WARNING: Use copper conductors only.

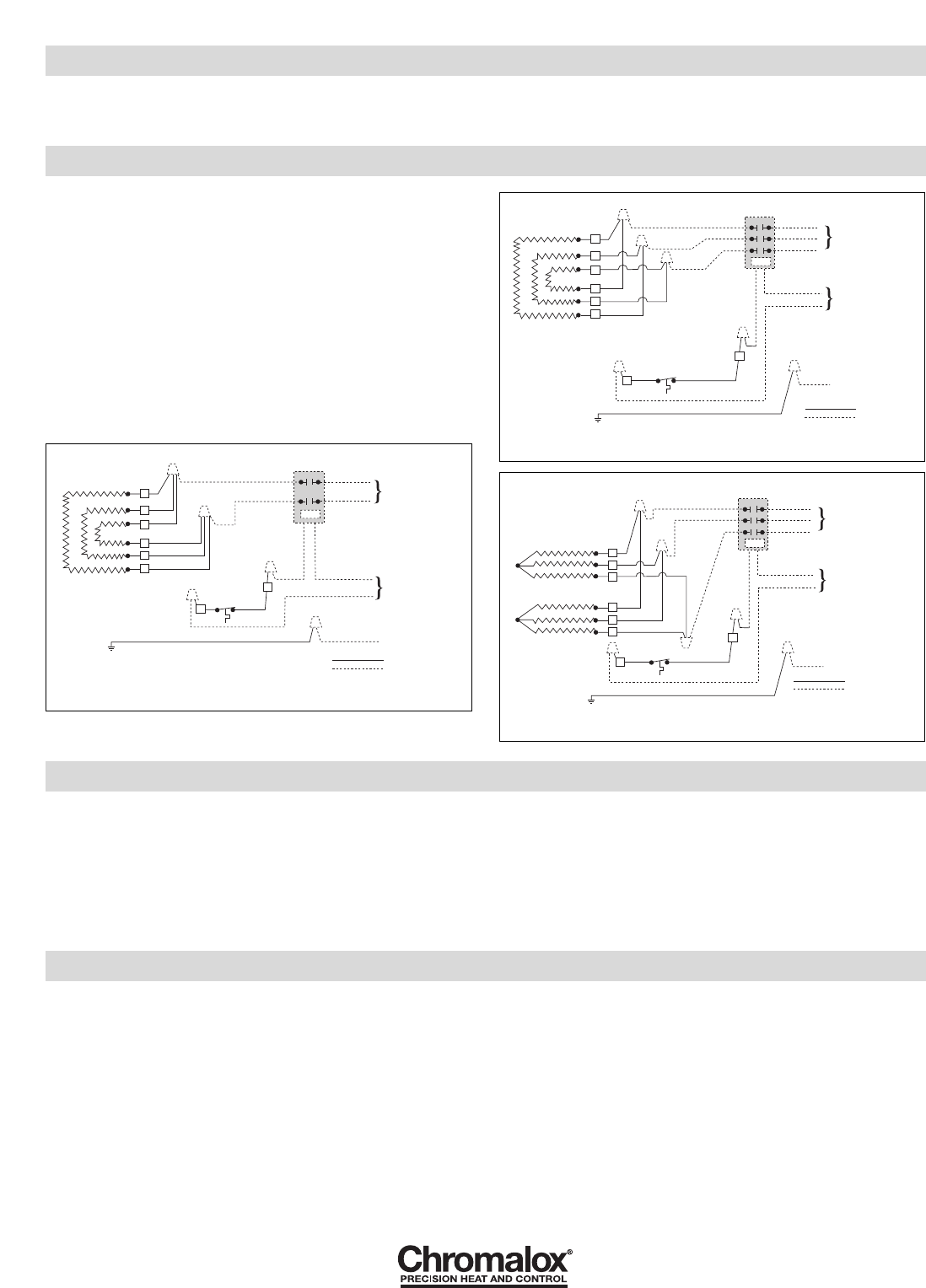

2. Wire heater with manual reset thermal cutout as shown in

Figures 2 thru 4.

Note:

1. Manual reset thermal cutout rating 25 amps 120-277 Vac.

2. Customer supplied thermostat/liquid level control wiring not

shown.

INSTALLATION

5. DANGER: Hazard of Fire. Since these heaters are capa-

ble of developing high temperatures, care should be taken to

maintain liquid level above heated portion (dimension B of

Figure 1) of heater.

OPERATION

1. Do not operate heater at voltages in excess of that stamped on

the heater since excess voltage will shorten heater life.

2. Always maintain a minimum of 2” of solution above the heater

portion of the element to prevent exposure of the effective heated

length. If the heater is not properly submerged, it may overheat

and shorten heater life. Do not operate heater if dry.

(Note: Heated portion of element is Dimension B of Figure 1).

3. Sludge should not be allowed to build-up to the point where it

contacts heater as this can lead to premature heater failure.

4. Maximum recommended process temperature is 212˚F.

5. If manual reset cutout trips, disconnect power to heater and

check for cause of overheat condition. Correct condition, then

remove heater terminal cover and push black reset button to reset

the cutout. Assemble terminal cover before re-energizing heater.

MAINTENANCE

WARNING:

Hazard of Severe Shock. Disconnect all

power to heater before servicing or replacing heaters.

1. Heaters should be checked periodically for corrosion buildup

and cleaned if necessary.

2. Tank should be checked regularly for sediment around the end

of heater as this sediment can act as an insulation and shorten

heater life.

3. WARNING: Do not scratch or scrape thermal cutout capil-

lary when cleaning. Cleaning should be done chemically.

C1

1

2

3

3

2

1

C2

2 Pole Contactor

Customer Supplied

Line Voltage

Ground

Factory

Field

Cutout

Green

120V or 240V

Control Circuit

C1

1

3 Pole Contactor

Customer Supplied

Line Voltage

Ground

Factory

Field

Cutout

Green

120V or 240V

Control Circuit

2

3

3

2

1

C2

C1

3 Pole Contactor

Customer Supplied

Line Voltage

Ground

Factory

Field

Cutout

Green

120V or 240V

Control Circuit

C2

1

2

3

1

2

3

Single Phase for:

PTHF-302, -304, -402, -404

Figure 2

Figure 3

Three Phase for:

PTHF-602, -604, -802, -804, -1002, -1004

Three Phase for:

PTHF-302, -304, -402, -404

Figure 4

2150 N. RULON WHITE BLVD., OGDEN, UT 84404

Phone: 1-800-368-2493 www.chromalox.com

TA - Q0 - EF

Litho in U.S.A.

Limited Warranty:

Please refer to the Chromalox limited warranty applicable to this product at

http://www.chromalox.com/customer-service/policies/termsofsale.aspx.