OPERATION

1. Do not heat solutions that are corrosive to the heating element

sheath or the heating chamber.

WARNING: Type NWH Circulation Heaters are

equipped with copper heating elements and galva-

nized-steel heating chambers. It is the responsibil-

ity of the user to know the chemical composition

of the corrosive solution and the character of the

materials entering the solution as well as the cor-

rosive effect of the solution upon the heating ele-

ments and chamber. Chromalox cannot warrant

any electric circulation heater against failure by

sheath corrosion if such failure is the result of

operating conditions beyond our control.

2. Terminal ends of heater must be protected from drippings,

condensation, spray or direct spill-over of material. Their

presence at the terminals may damage heater electrical insula-

tion. Liquid-tight terminal enclosures are available to protect

heater. Contact your Local Chromalox Sales office.

3. If foreign material is carried by the liquid flow, install suitable

filters in the inlet pipe line to the heater.

4. Do not allow heater to operate when liquid flow is interrupted.

MAINTENANCE

1. WARNING:

Hazard of Electric Shock. Disconnect all

power before servicing heater.

2. Remove heating element assembly periodically to check

heater sheath for scaling, corrosion or excessive oxidation.

Correct operating conditions to minimize sheath deterioration.

3. Periodically check temperature control and limit control oper-

ation to insure accurate and safe process operation.

4. Check all electrical connections periodically and retighten

connections which may have loosened in service. Replace wire

and wire terminals which show signs of oxidation which would

interfere with establishment of reliable electrical connections.

WIRING

WARNING: Hazard of Electric Shock. Any installation

involving electric heaters must be effectively ground-

ed in accordance with the National Electrical Code to

eliminate shock hazard.

1. Be sure line voltage matches heater voltage (on nameplate).

2. Electric wiring to heater must be installed in accordance with

local and National Electrical Codes.

3. Power controllers must be used when heaters are rated 3 phase and

when the heater amperage exceeds the rating of the thermostat.

4. Refer to Wiring Diagram, Table B, for the proper wiring diagram

for connecting

heater.

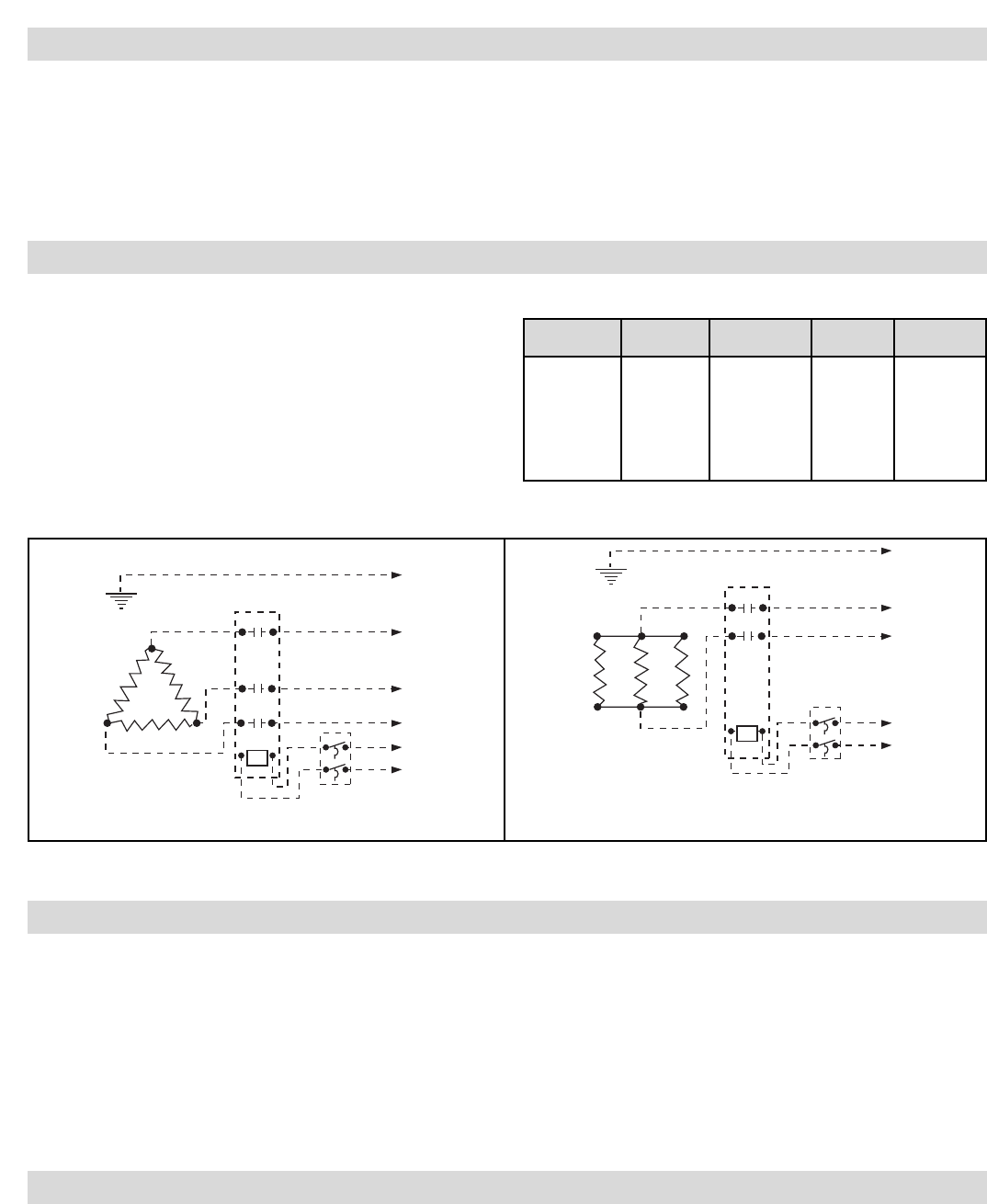

Wiring Diagrams - Table B

INSTALLATION

3. Whether vertically or horizontally, the heater should be rigidly

mounted so that vibration is at a minimum since excessive

vibration will result in erratic thermostat operation. The

NWH-3 is provided with mounting lugs to support the heating

chamber. (See photo.)

4. By using a slotted mounting assembly on either of the lugs,

the heater chamber will be permitted to expand with increas-

ing temperature.

5. DANGER: Hazard of Fire. Provide minimum of 6” spac-

ing from chamber and related piping to nearest combustible

material. Avoid operation of heater near combustible fluids or

in combustible vapor or gas laden atmosphere.

6. Provide adequate space at terminal end to permit withdrawal

of the heater from chamber should servicing be required.

Model

240V, 240V, 480V, 480V,

1 Ø Fig. 3 Ø Δ Fig. 1 Ø Δ Fig. 3 Ø Δ Fig.

NWH-3625 2 1 2 1

NWH-3925 2 1 2 1

NWH-31225 2 1 2 1

NWH-31525 2 1 2 1

NWH-31825 2 1 2 1

Ground

Contactor

Thermostat

L1

L2

L3

120V

or

240V

Note: Dotted lines indicate “customer furnished.” However, Thermostat could have been furnished by Chromalox if so specified on the order.

Figure 1

240V, 480V 3ØΔ

Figure 2

240V, 480V, 1Ø

Use contactor when the heater amperage

exceeds the rating of the thermostat.

Ground

Contactor

Thermostat

Line

120V

or

240V