SOLID STATE FLOATLESS LIQUID LEVEL

CONTROL SYSTEM

This boiler is equipped with a solid state, floatless liquid level

control which operates by sensing the electrical resistance of

water. Note: Control will not work with de-ionized or demineral-

ized water. Two probes are provided. The HI probe activates and

controls the feed water relay. The LOW probe is a safety back-up

probe that turns off the power to the element in the event of low

water. A 12 volt potential is established between each probe and

ground. The presence or absence of water generates a small signal

that is amplified and fed to a SCR. The SCR, in turn, activates a

relay, depending on the function and the water level.

ADJUSTING PRESSURE CONTROLS

Chromalox boilers are supplied with operating and high limit pres-

sure controls. One is used for controlling the operating pressure of

the boiler while the other is used as a high limit control.

MANUAL BLOWDOWN INSTRUCTIONS

Blowdown is an essential part of boiler operation. It is the best

preventive maintenance you can give your boiler and will add

years of life to the unit. Make sure a blowdown schedule is estab-

lished and followed regularly.

Blowdown will remove accumulated hard water scale and dis-

lodge scale from water heating surface thereby insuring efficient

heating. In extremely hard water areas blowdown is necessary

once a day. In soft water areas, once each week. If water is known

to be corrosive, consult water treating specialists to recommend

water treatment needed to insure corrosion free boiler operation. If

there is a particular problem which applies to your own local water

condition other than mineral content, take this into consideration

in determining what schedule is to be followed.

1. At the end of the working day turn switch to the OFF position

and close water supply valve. De-energize wall mounted safe-

ty switch (main power supply).

2. If blowing down into a receptacle, cover receptacle to prevent

splash of scalding water.

3. It is preferable to connect the blowdown valve directly into a

drainage system. If this is done, the boiler can be discharged at

operating pressure. However, check local codes and suitability

of drainage system before connecting.

4. When blowdown is complete and boiler is drained (a) close the

blowdown valve; (b) open water supply valve; (c) put boiler

switch in the ON position; and, (d) close wall mounted safety

switch.

5. When refilling is complete, turn off the boiler switch unless

further operation is desired.

The use of chemical boiler cleaning compounds in these boilers

voids all warranties unless approved by Chromalox, Inc.

-3-

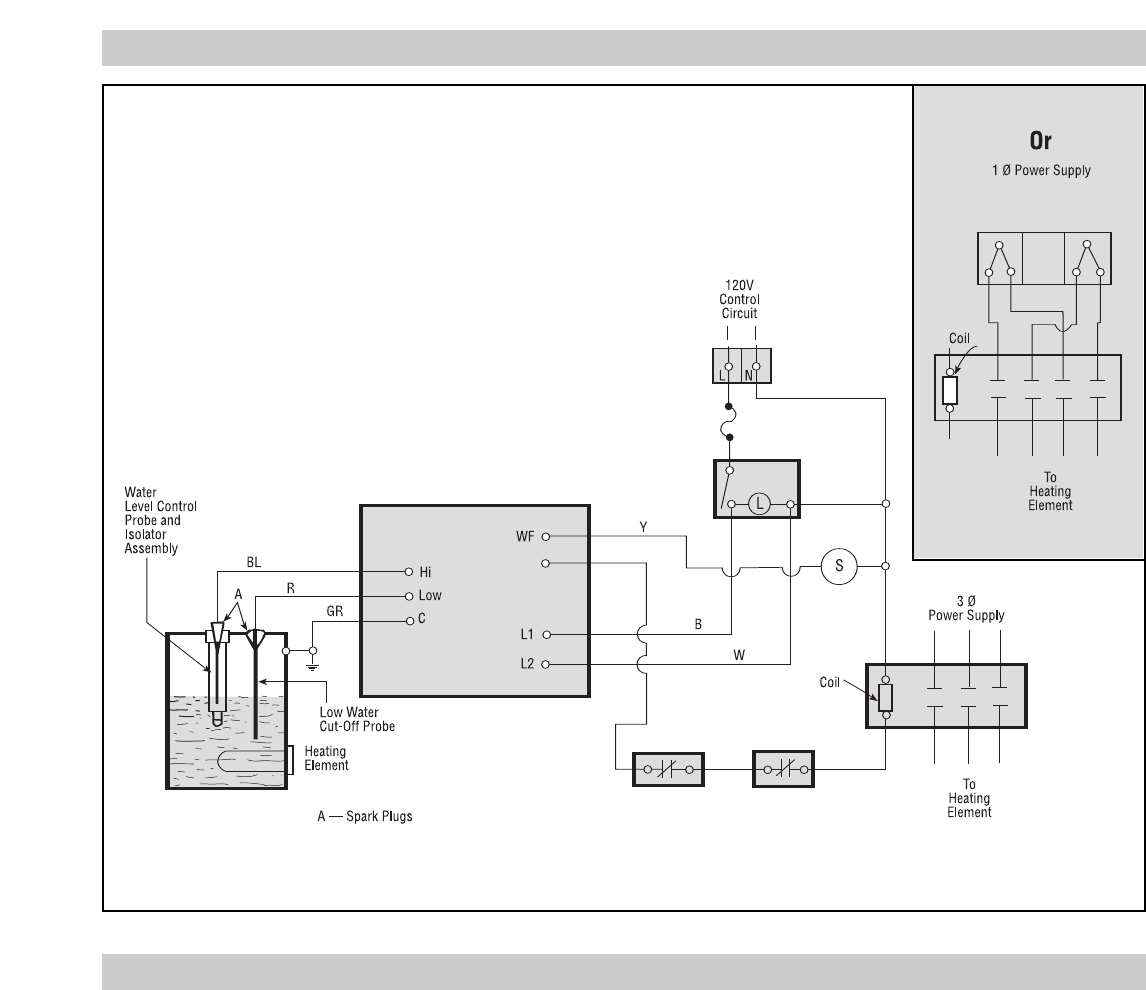

SCHEMATIC WIRING DIAGRAM

OPERATION

HTR

O

Wire Color Code —

B = Black

W = White

R = Red

O = Orange

Y = Yellow

GR = Green

BL = Blue