31

Radiance Direct Vent /Natural Vent Gas Heater

20004188

CO100

Gas conversion

HI-LO knob

3/15/99 djt

L

O

H

I

L

O

H

I

Cap

Hi-Lo

Knob

Lift Open

Center Screw

CO100

Fig. 55 Remove center screw from Hi-Lo knob.

14. Tighten screw (do not over tighten), replace cap.

15. Locate pilot. (Fig. 53)

16. Replace pilot orifice.

Pilot Type 1 (SIT Pilot)

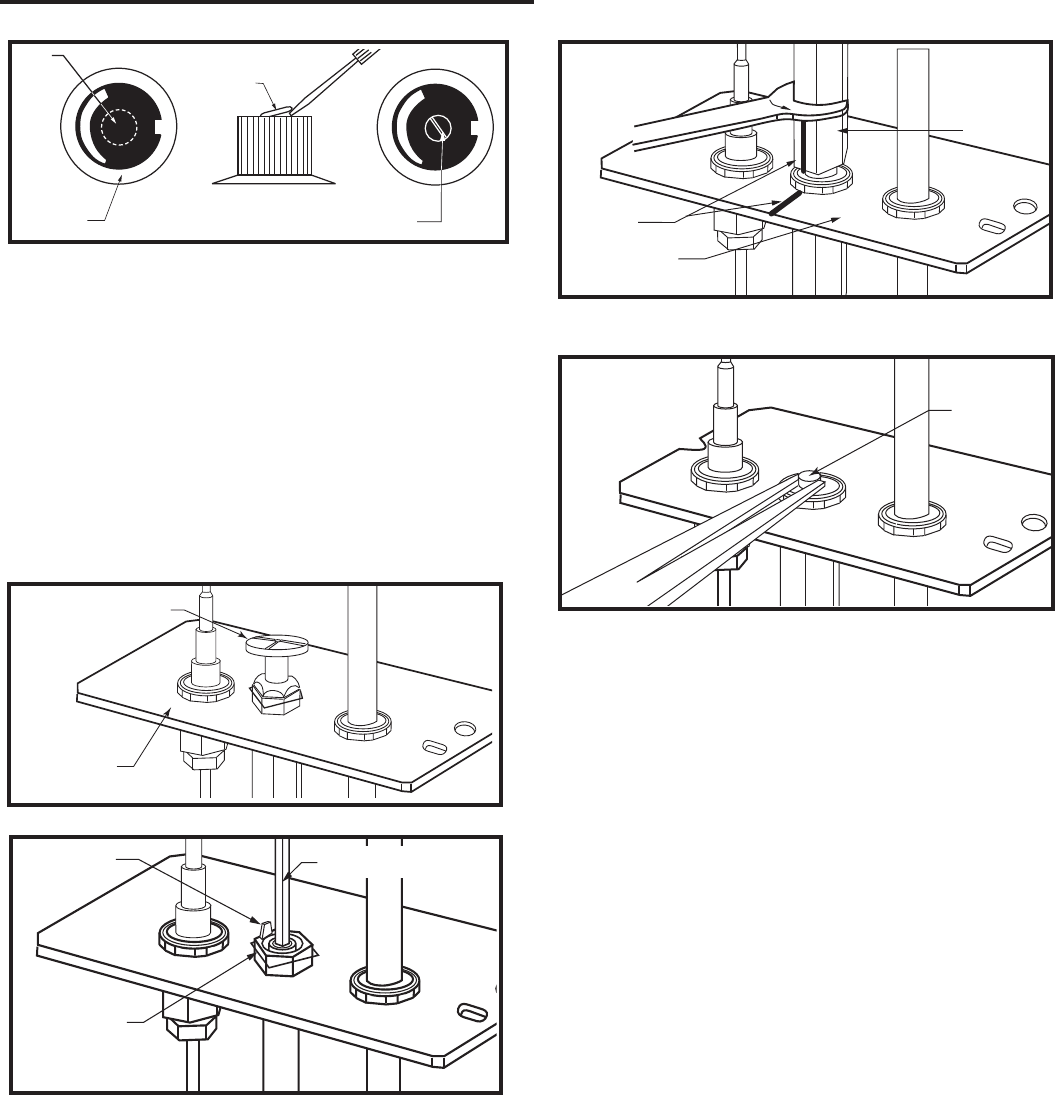

• Remove pilot hood by lifting up. (Fig. 56) Do not

remove the snap ring to remove the pilot hood.

NOTE: It is not necessary to remove the pilot tube

for conversion.

• Remove pilot orifice with allen wrench. (Fig. 57)

• Install the conversion orifice.

• Reinstall pilot hood. Be sure to align hood with

index tab.

CO105a

gas conversion

Pilot

1/28/00 djt

Pilot Hood

Pilot

Bracket

CO105a

Fig. 56 Remove pilot hood.

CO106a

DV360/580

Gas Conversion

Pilot2

1/28/00 djt

Index Tab

Snap Ring

Allen Wrench

CO106a

Fig. 57 Remove pilot orifice.

CO105

Gas Conversion

Pilot

2/15/99 djt

Pilot Hood

Index

Marks

Pilot Bracket

CO105

Fig. 58 Remove pilot hood. (Your pilot may have a different

appearance.)

CO106a

Gas Conversion

Pilot (Vermont)

7/19/99 djt

Pilot

Orifice

CO106b

Fig. 59 Remove pilot orifice.

Pilot type 2 (Honeywell Pilot)

• Loosen pilot hood turning counterclockwise using a

7/16” wrench. (Fig. 58) NOTE: You may use pen-

etrating oil to prevent pilot hood threads from seizing

up.

• Remove pilot orifice with needlenose pliers. (Fig.

59) NOTE: Use a wrench to hold pilot tube in place

while removing the orifice.

• Install the conversion orifice.

• Reinstall pilot hood and tighten until mark on pilot

hood aligns with mark on pilot bracket.

NOTE: Be sure burner leg remains at a 90° angle to

firebox base after conversion.

Models 3352, 3354, 3390 thru 3399 (RF Models) Only

17. Follow procedure for pilot type 2 to replace pilot

orifice.

18. Remove and replace plug on lower right hand side

of the valve; Red for LP and Blue for NG. (Page 26,

Fig. 49)

19. Remove motor top cap. Depress and turn center

plunger until arrow points to correct screw. Red for

LP and Blue for NG. NOTE: Plunger will “snap” into

NG position when arrow is close to blue screw. It will

not “snap” at LP (Red) position. (Fig. 60)

20. Insure manifold pressure remains between 3.2”

- 3.5” w.c. for NG and 9.5” - 10” w.c. for LP. To adjust

the manifold pressure, for NG, using a torque #10 key

turn the blue screw clockwise to increase the manifold

pressure. Turn the screw counterclockwise to de-

crease the pressure. Use the red screw to adjust LP.

21. Replace motor top cap.