15

DVHVAC36

10001195

• IMPORTANT • Minimum clearance between vent

pipes and combustible materials is 1" (25mm) on bot-

tom, sides and top.

A vent starter kit plus a transition elbow

must be used in Vertical Sidewall Installa

-

tions. The 4" pipe must be centered inside

the 7" pipe coming off the transition elbow.

Canadian & USA Installations:

The venting system must conform with local codes, or

in the absence of local codes, with the National Fuel

Gas Code, ANSI Z223.1/NFPA 54 - latest edition, or

CSA B149.1 Installation Code.

Only CFM Corporation venting components specifically

approved and labelled for this fireplace may be used.

Vertical Sidewall Installations

STEP 1

Locate vent opening on the wall. It may be necessary

to first position the fireplace and measure to obtain hole

location. Depending on whether the wall is combustible

or noncombustible, cut opening to size. (Fig. 22)

For combustible walls first frame in opening.

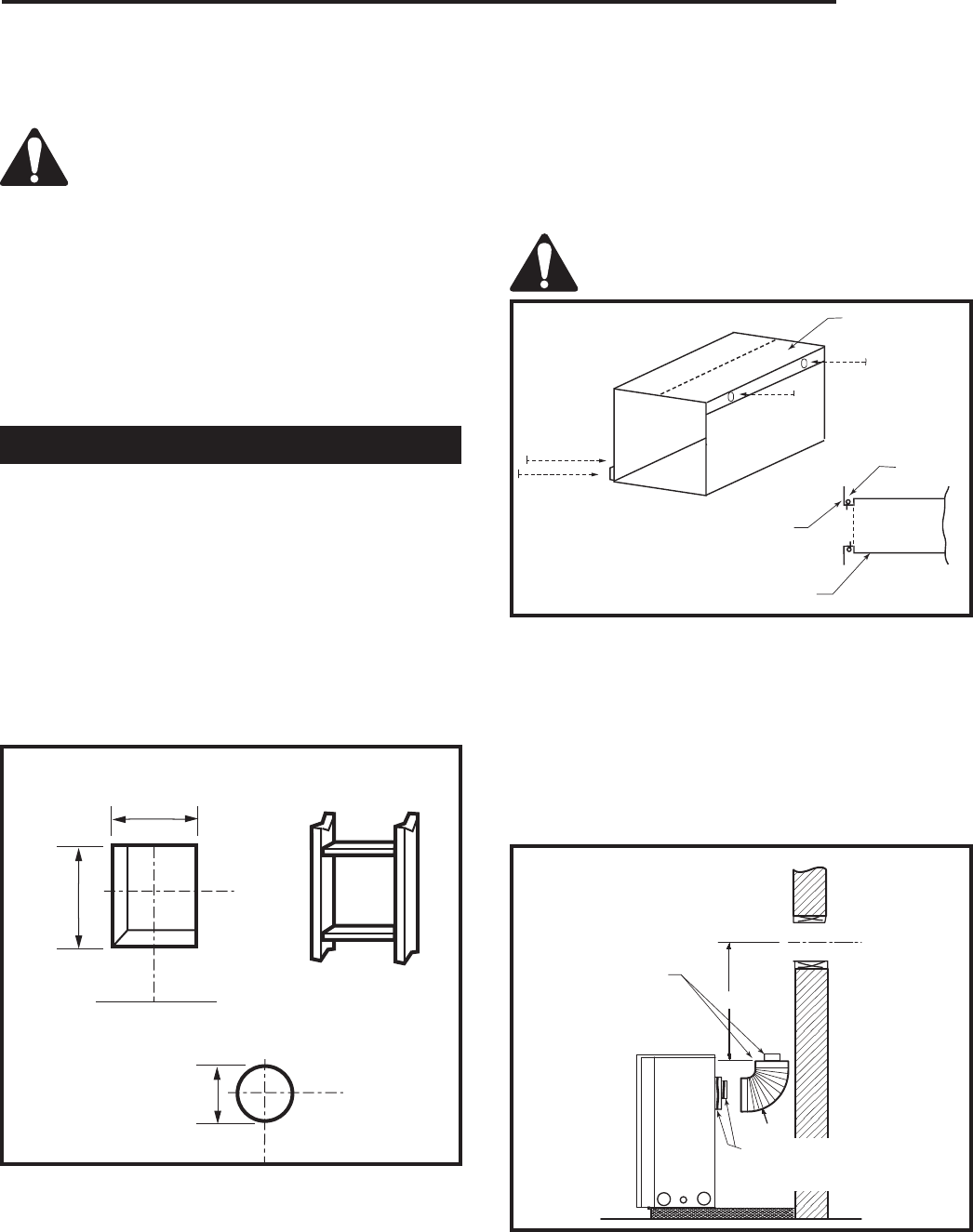

Combustible Walls (Fig. 22): Cut a 9³⁄₈" x 9³⁄₈" (240 x

240 mm) hole through the exterior wall and frame.

Noncombustible Walls (Fig. 22): Hole opening must

be 7¹⁄₂" (190 mm) in diameter.

VO584-100

Vent Opening

2/99 djt

Vent Opening for Combustible Wall

9³⁄₈"

(240 mm)

9³⁄₈"

(240 mm)

Fireplace

Hearth

Framing

Detail

Vent Opening for Noncombustible Wall

7¹⁄₂"

(190 mm)

VO584-100

Fig. 22 Locate vent opening on wall.

STEP 2

Measure wall thickness and cut adjustable zero clear-

ance sleeve parts to proper length (MAXIMUM 12" /

305mm). (Fig. 23) Adjust sleeve to minimum (9³⁄₈" x 9³⁄₈"

/ 240 x 240 mm) and attach to firestop with #8 sheet

metal screws (supplied). Assemble sleeve and attach

to firestop with #8 sheet metal screws (supplied). Install

firestop assembly.

Zero clearance sleeve is only required for

combustible walls.

ZCS101

Zero Clearance Sleeve

3/11/99 djt

Max. Length

12" (305 mm)

Adjustable

Zero Clearance

Sleeve

#8 Screws

(2)

#8 Screws (2)

#8

Screws

(2)

Firestop

Adjustable Zero Clearance Sleeve

ZCS101

Fig. 23 Adjustable zero clearance sleeve.

STEP 3

Apply a bead of high temperature sealant to the inner

and outer flue collars of the fireplace and using ap-

propriate venting component(s) attach to fireplace with

three (3) screws. (Fig. 24) Follow with the installation

of the inner and outer elbow. Again, secure joints with

three (3) sheet metal screws. Wipe off any excess high

temperature sealant.

CFM143

2/2/01 sta

CFM143

Ensure Pipes

are Concentric

Bead of Seal-

ant

(If Necessary)

Fig. 24 Apply sealant to inner and outer pipe.