8

Madison Woodburning Stove

30001453

Floor Protection

A tremendous amount of heat radiates from the

bottom plate of your Madison. The floor area directly

under and around the stove will require protection from

radiant heat as well as from stray sparks or embers

that may escape the firebox.

Heat protection is provided through the use of a

Bottom Heat Shield #1892. Spark and ember protec-

tion must be provided by a floor protector constructed

with noncombustible material as specified.

Most installations will require that the bottom heat

shield be attached. Only when the stove is placed on a

completely noncombustible surface such as unpainted

concrete over earth may it be used without the heat shield.

Even when the bottom heat shield is installed, you

must provide special protection to the floor beneath.

For installations with the heat shield attached, use a

noncombustible floor protector such as 1/4” non-

asbestos mineral board or equivalent, or 24 gauge

sheet metal. The floor protector may be covered with a

noncombustible decorative material if desired. Do not

obstruct the space under the heater.

Protection requirements vary somewhat between the

United States and Canada as follows:

For U.S. installations the floor protector is required

under the stove and must extend at least 18” from the

front of the stove (“D”, Fig. 12), at least 4” from the

right side and rear (“C”, Fig. 12) and 16” from the left

side (“E”, Fig. 12). It must also extend under the

chimney connector and 2” to either side (“F”, Fig. 12).

To meet these requirements, a floor protector must be

at least 48” wide (“A”,Fig. 12) and 48” deep (“B”,Fig.

12)

In Canada, a noncombustible floor protector is re-

quired under the heater also. The floor protector must

extend 18” (457mm) to the front (D), and 8” (203mm)

from the right side (C) and rear (C) and 18” (457mm)

from left side (E).

Fig. 9 Wall Pass-through using single wall chimney

connector with a ventilated steel thimble.

Min. 6"

(152mm)

Chimney clearance to sheet

steel supports and combustibles

2" (51mm) Min.

Glass Fiber

Insulation

Chimney Connector

Chimney Flue

Steel Thimble

with two 1"

(25mm) Ventilated

Channels

Masonry Chimney

constructed to NFPA 211

24 ga.Sheet

Steel Supports

ST274

• Placing a chimney connector pipe inside a section

of 9" (230 mm) diameter, solid-insulated, factory-

built chimney, with two inches of air space between

the chimney section and combustibles. (Fig. 10)

Canadian Requirements:

In Canada, the Canadian Standards Association has

established specific guidelines regarding wall pass-

though design. Figure 11 shows one approved method

in which all combustible material in the wall is cut away

to provide the required 18" (457mm) clearance around

the connector. The resulting space must remain

empty. A flush-mounted sheet metal cover may be

used

on one side only. If covers must be used on both

sides, each cover must be mounted on noncombus-

tible spacers at least 1" (25mm) clear of the wall. Your

local dealer or your local building inspector can provide

details of other approved methods of passing a chim-

ney connector through a combustible wall.

In Canada, this type of installation must conform to

CAN/CSA-B365, Installation Code for Solid Fuel

Burning Appliances and Equipment.

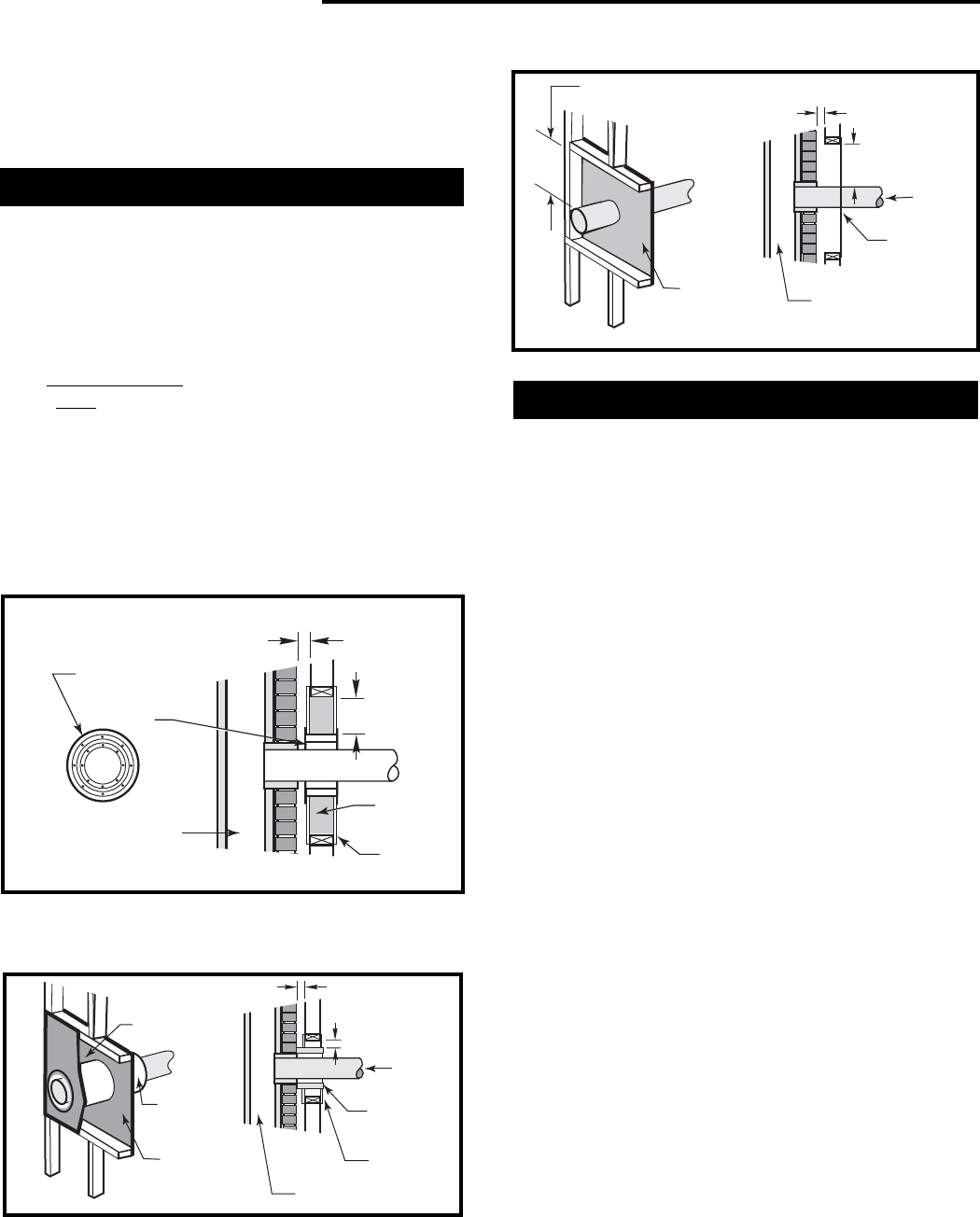

Fig. 11 CSA approved Wall Pass-through.

24 ga.Sheet

Steel Support

24 ga. Sheet

Steel Support

(one side only)

Min. 18"

(460mm)

Chimney clearance to sheet steel

supports and combustibles

2" (51mm)

Min.

Chimney Flue

Chimney

Connector

Masonry Chimney

constructed to CAN/CSA-

B365

Min. 18"

(460mm)

ST276

Fig. 10 Wall Pass-through with ventilated steel thimble.

24 ga. Sheet

Steel Supports

24 ga. Sheet

Steel Supports

2" (51mm) Min.

Chimney clearance to sheet steel

supports and combustibles

2" (51mm)

Min.

Chimney Flue

2" (51mm) Min.

air space

Prefab

Chimney

Section

Prefab

Chimney

Section

Chimney

Connector

Masonry Chimney

constructed to NFPA 211

ST275