Step 10—Electrical Connections

115-V WIRING

Refer to the unit rating plate or Table 6 for equipment electrical

requirements. The control system requires an earth ground for

proper operation.

Do not connect aluminum wire between disconnect switch

and furnace. Use only copper wire.

Make all electrical connections in accordance with the current

edition of the National Electrical Code (NEC) ANSI/NFPA

70-1999, and any local codes or ordinances that might apply. For

Canadian installations, all electrical connections must be made in

accordance with Canadian Electrical Code CSA C22.1, or authori-

ties having jurisdiction.

NOTE: Proper polarity must be maintained for 115-v wiring. If

polarity is incorrect, control status code indicator light will flash

rapidly and furnace will not operate.

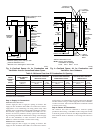

Fig. 10—Horizontal Crawlspace Installation on Hanger Rods

A96633

NOTES:

ANGLE

IRON OR

EQUIVALENT

ROD LOCATION

USING DIMPLE

LOCATORS

(SEE DIMENSIONAL

DWG FOR

LOCATIONS)

3

⁄8-IN. ROD

1. A 1 In. clearance minimum between top of

furnace and combustible material.

2. The entire length of furnace must be

supported when furnace is used in horizontal

position.

3

/8-IN. HEX NUT

& WASHER (4)

REQD PER ROD

(A) PREFERRED ROD LOCATION

(B) ALTERNATE ROD LOCATION

(A)

(B)

(A)

(B)

(B)

(A)

(A)

(B)

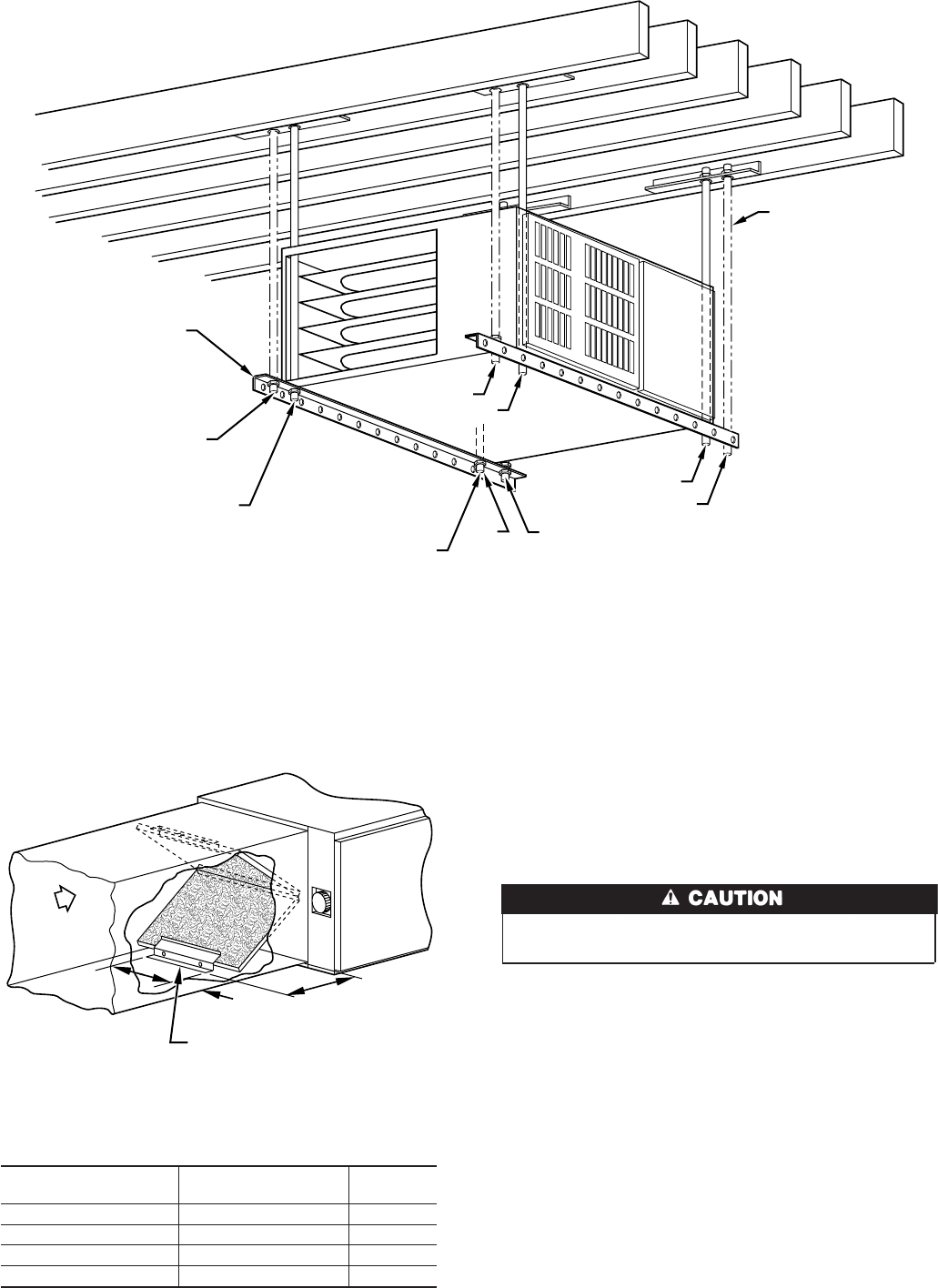

→Table 4—Filter Retainer (In.)

FURNACE CASING

WIDTH

FILTER SIZE AND

QUANTITY

D

14-3/16 (2) 16 X 20 X 1 15-3/8

17-1/2 (2) 16 X 20 X 1 14-3/4

21 (2) 16 X 20 X 1 13-3/4

24-1/2 (2) 16 X 20 X 1 12-1/2

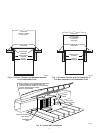

Fig. 11—Horizontal Filter Arrangement

A82173

FIELD-SUPPLIED

FILTER RETAINERS

AIRFLOW

D

12

″

4

″

10