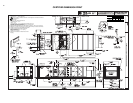

Date: Supersedes:

50JB034, 038, 044, 048, 054, 064

SINGLE-PACKAGE COOLING UNITS,

EXTENDED CHASSIS

PRODUCT INTEGRATED CONTROLS

50JB

Rev.:

JOB NAME: LOCATION:

BUYER: BUYER P.O. # CARRIER #

UNIT NUMBER: MODEL NUMBER:

PERFORMANCE DATA CERTIFIED BY: DATE:

DESCRIPTION

50JB units are completely packaged, pre-wired and precharged cooling only units with PRODUCT

INTEGRATED CONTROLS.

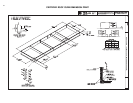

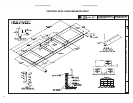

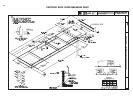

50JB units are built for horizontal supply and return applications. Their waterproof construction makes

them ideally suited for installation on the accessory roof curb which is NRCA approved or slab mounting.

Units are either CONSTANT VOLUME or VARIABLE AIR VOLUME depending on the factory-

installed options selected.

Units include space and coil tracks downstream of evaporator for field or factory installation of auxiliary

devices.

PRODUCT INTEGRATED CONTROL FEATURES

STANDARD CONTROL FUNCTIONS

Unit compatible with CARRIER COMFORT NETWORK or stand

alone operation.

Constant Volume or Variable Air Volume control.

Four to six stages of compressor unloading possible.

Supply fan control based on occupancy schedule using 365-day

electronic timeclock with holiday scheduling.

Time schedule override through the space temperature sensor

provided with the unit.

Compatible with 37H and 45 Series PIC terminals to form a

Digital Air Volume system (DAV).

Building pressurization control in conjunction with modulating power

exhaust option.

Supply duct static pressure controlled through inlet guide vanes or

field or factory supplied inverter.

Head pressure control to −20° F. Head pressure controlled by

saturated condensing temperature, low ambient control utilizes

Motormaster II fan cycling.

Lead-lag compressor control to even out run time.

Self-diagnostic run test confirms control and component operation

at unit commissioning. Self-diagnostic troubleshooting codes

indicate the reason unit tripped to expedite unit repair. Codes

expand to English Text.

Control of a two-speed supply fan motor on CV applications. (Two-

speed motor available on Special Order.)

Building Purge Mode flushes building interior with outdoor air to

remove contaminants before occupancy.

Adaptive Optimal Start minimizes the amount of time and energy

required before entering the occupied mode.

Unoccupied Mode Free Cooling — units with optimal economizer

will utilize free cooling whenever possible to maintain the unoc-

cupied set point.

Input/Output of data and monitoring of alarms can be done

remotely using Building Supervisor, or at the unit using the

accessory HSIO module.

Delayed Mechanical Cooling — units with optional economizer

will utilize cooling to cool the space 3 degrees below the occupied

set point to delay the need for mechanical cooling.

ADDITIONAL CONTROL FUNCTIONS

AVAILABLE THROUGH FACTORY-INSTALLED ‘‘OPTION MODULE’’

Provides a discrete output with occupancy control for use as speci-

fied by the customer.

Controls a field installed humidifier usinga4to20mAor2-stage

output. Requires accessory humidity sensor.

Smoke Control functions (Building Pressurization and Smoke Purge)

are provided through software. Terminals are provided to interface

with field supplied smoke/fire panel.

Providesa4to20mAoutput to direct or reverse proportional hot

water control valve for field supplied hydronic heating coil. Re-

quires a field supplied freezestat to protect coil.

Factory installed suction and discharge pressure transducers and

suction temperature thermistors allow remote monitoring of these

parameters and superheat to provide enhanced remote diagnostics.

Differential enthalpy control can be provided using field installed

accessory humidity sensors.

Economizer control field configurable to:

— Maintain a minimum economizer set point position,

OR

— Maintain the minimum economizer position based on input from

an IAQ sensor (field supplied0-10volt),

OR

— Maintain a constant cfm of outdoor air intake (Requires

accessory Outdoor Air CFM package),

OR

— Look at all three above and maintain minimum economizer

position based on the dominant parameter.

2