Air Filter(s) — Air filter(s) should be checked at least

every 3 or 4 weeks and changed or cleaned when necessary.

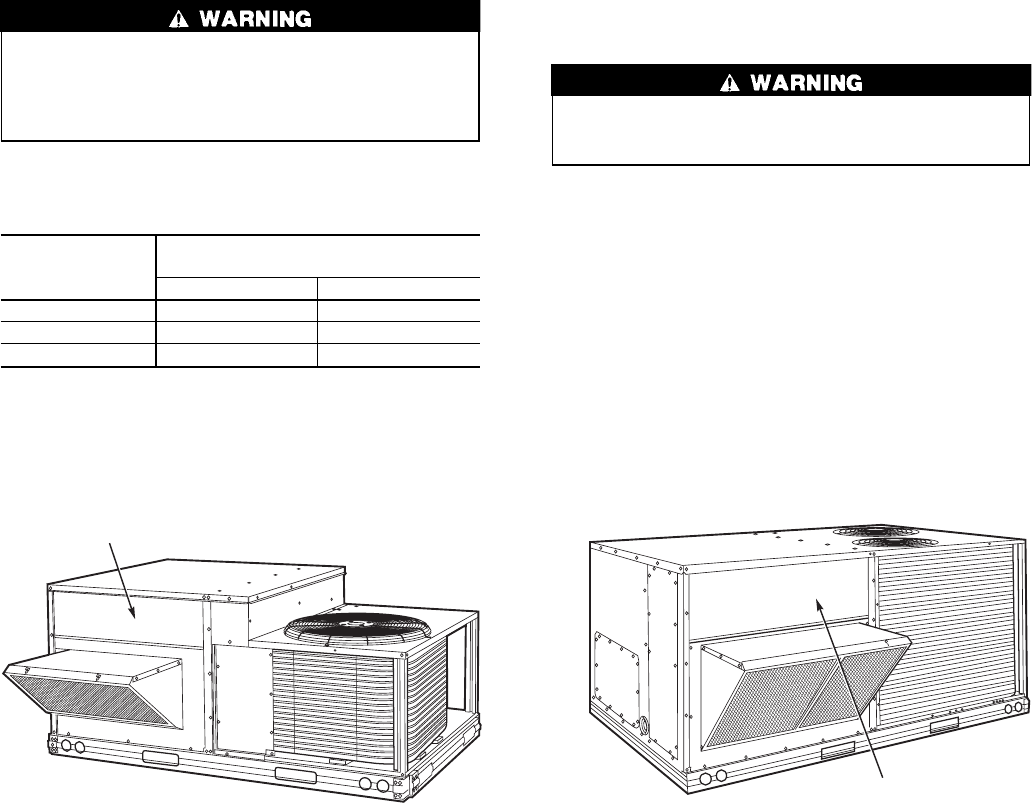

Table 1 indicates the correct filter size for your unit. See Fig. 4

for filter access door location.

To replace or inspect filters:

1. Lift up and remove filter access panel.

2. While holding filter, tilt upper filter rack.

3. Remove filters by pulling up and out toward you from

the track.

4. Inspect or replace filters.

5. Return filters to filter track. Note direction of airflow ar-

rows on filter frame.

6. Replace filter access panel.

If you have difficulty in locating your air filter, or if you

have questions concerning proper filter maintenance, con-

tact your dealer for instructions. When replacing your unit

filters, always use the same size and type of filter that was

originally supplied by the installer.

Units with outdoor air capability have a cleanable filter

for the outdoor air. This filter should be checked annually

and cleaned as necessary with steam or hot water and a mild

detergent. Do not use throwaway filters in place of cleanable

filters.

Never operate your unit without filters in place. Failure

to heed this warning may result in damage to the blower

motor and/or compressor. An accumulation of dust and

lint on internal parts of your unit can cause loss of ef-

ficiency and, in some cases, fire.

Table 1 — Indoor-Air Filter Data

UNIT SIZE

48TJ

INDOOR-AIR FILTERS

(Throwaway Fiberglass)

QUANTITY SIZE (in.)

004-007 2 16x25x2

008,009 4 16x20x2

012,014 4 20x20x2

NOTE: Replacement filters should be UL (Underwriters’ Laborato-

ries) certified or equivalent.

Heat Exchanger — To ensure dependable and efficient

heating operation, the heat exchanger should be checked by

a qualified maintenance person before each heating season,

and cleaned when necessary. This checkout should not be

attempted by anyone not having the required expertise and

equipment to do the job properly. Checking and/or cleaning

the heat exchanger involves removing the gas controls as-

sembly and the flue collector box cover and, when com-

pleted, reinstalling the gas controls assembly for proper op-

eration. Also, the flue collector box cover must be replaced

correctly so that a proper seal is maintained. Contact your

dealer for the required periodic maintenance.

Fans, Belts and Fan Motor — Periodically check the

condition of the fan wheels and housings, belt tension and

fan motor shaft bearings. No lubrication of condenser or evapo-

rator fan bearings or motors is required or recommended.

Evaporator and Condenser Coils — Cleaning of

the coils should be done by qualified service personnel. Contact

your dealer for the required annual maintenance.

Condensate Drain — The drain pan and condensate

drain line should be checked and cleaned at the same time

the cooling coils are checked by your dealer.

Compressor — All compressors are factory supplied with

a normal charge of the correct type refrigeration-grade oil in

them and should not require additional oil.

Condenser Fan

Do not poke sticks, screwdrivers, or any other

object into revolving fan blades. Severe bodily injury

may result.

The fan must be kept free of all obstructions to ensure

proper cooling. Contact your dealer for any required service.

Electrical Controls and Wiring — Electrical con-

trols are difficult to check without proper instrumentation;

therefore, if there are any discrepancies in the operating cycle,

contact your dealer and request service.

Refrigerant Circuit — The refrigerant circuit is diffi-

cult to check for leaks without the proper equipment; there-

fore, if inadequate cooling is suspected, contact your local

dealer for service.

48TJ004-007 48TJ008-014

Fig.4—Typical Filter Access Panel Location

FILTER ACCESS PANEL

FILTER ACCESS PANEL

5