2

Step 4 — Check Unit Operation and Make

Necessary Adjustments

NOTE: Gas pressure must not be less than 5 in. wg or greater

than 13 in. wg at the unit connection.

1. Remove pressure tap plug from manifold pipe and

connect a pressure gage or manometer.

2. Turn on electrical supply.

3. Open the manual shutoff valve on the gas supply pip-

ing. Check pipe connection to main gas valve for

leaks.

4. Set the switch on the main gas valve to the ON position.

5. Call for high stage heat (W2 energized). The unit may

require several ignition attempts due to trapped air in

the manifold pipe.

6. When main burners ignite check orifice fittings for

leaks. Repair if necessary.

7. Verify that manifold pressure is between 2.7 and

3.0 in. wg while in high fire (W2 energized). Readjust

pressure if necessary.

8. Shut down unit by turning down thermostat (units with

electro-mechanical control) or putting unit in Service

Test mode (units with ComfortLink™ control), shut-

ting off manual gas valve, and shutting down power to

unit.

Never use a match or other open flame to check for leaks.

Use a soap and water solution. Fire or serious injury could

result.

If unit is equipped with a 2-stage gas valve, ensure valve

has energized second stage (high fire) before adjusting

manifold pressure. Improper manifold pressures may cause

explosion or injury.

This unit is designed to operate at 3.0 in. wg (± 0.3 in. wg)

manifold pressure at high fire. Exceeding this pressure will

cause explosion or injury.

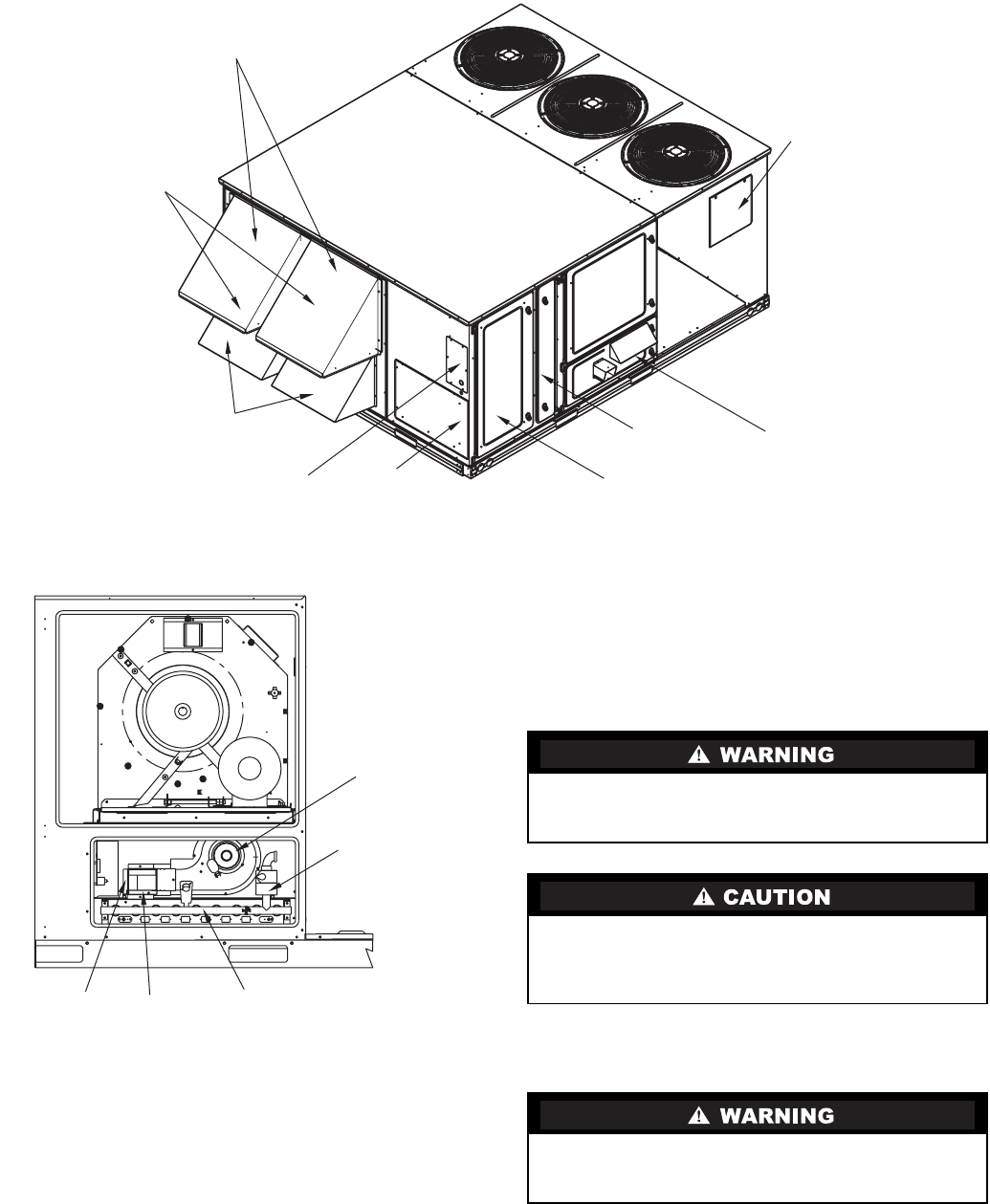

Fig. 1 — Panel and Filter Locations

CONDENSER

COIL ACCESS

PANEL

FILTER

ACCESS DOOR

CONTROL BOX

AND COMPRESSOR

ACCESS DOOR

BASEPAN

CONNECTIONS

ACCESS PANEL

BAROMETRIC

RELIEF DAMPER

HOODS

OUTDOOR AIR

SCREENS

(HIDDEN)

ECONOMIZER HOODS

ELECTRICAL

OPTIONS

PANEL

GAS SECTION

ACCESS DOOR

INDUCED

DRAFT

MOTOR

MAIN GAS

VALVE

MAIN

BURNER

SECTION

COMBUSTION

FAN HOUSING

HEAT

EXCHANGER

SECTION

Fig. 2 — Typical Gas Heating Section