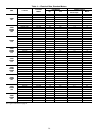

Table 6 — Fan Contactor Coil Data

UNIT

40RM, 40RMQ

40RMS

VOLTAGE

(vac)

MAXIMUM

HOLDING

VA

007-034 24 10

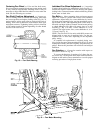

Connecting Ductwork — Refer to the Carrier Sys-

tem Design Manual for the recommended design and layout

of ductwork. Figure 15 shows recommended duct connec-

tion to units with 2 fans.

DISCHARGE CONNECTIONS — Duct flanges are factory

supplied; they are shipped inside the unit attached to the hair-

pin end of the coil tube sheet for field installation. Using the

existing screws, install the duct flanges on the unit’s fan deck.

Each fan discharge requires 2 flanges; each flange must be

bent in the middle to conform to the discharge opening. See

Fig. 16. After flanges are installed, connect them to the sup-

ply duct using a canvas connection to prevent vibration. It is

important that this connection be properly fabricated to pre-

vent high air friction losses and air noise.

RETURN CONNECTION — When using return-air duct-

work, route return-air duct to the unit’s return air inlet near

the filter rack, using a canvas connection to prevent trans-

mission of unit vibration. If the duct blocks off the unit’s

access panel, provide a slip joint in the ductwork to permit

removal for servicing.

OUTDOOR-AIR INLET CONNECTION — Connect outdoor-

air inlet to field-installed accessory economizer. Refer to econo-

mizer Installation Instructions.

Return-Air Filters — Type and size of filters are

shown in Tables 1A-1F and are factory-supplied and in-

stalled. In all units with 2 fans, a filter replacement tool (hook)

is shipped inside the unit for field use when replacing filters.

See the Service section for instructions on filter element

replacement.

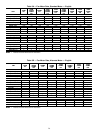

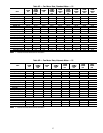

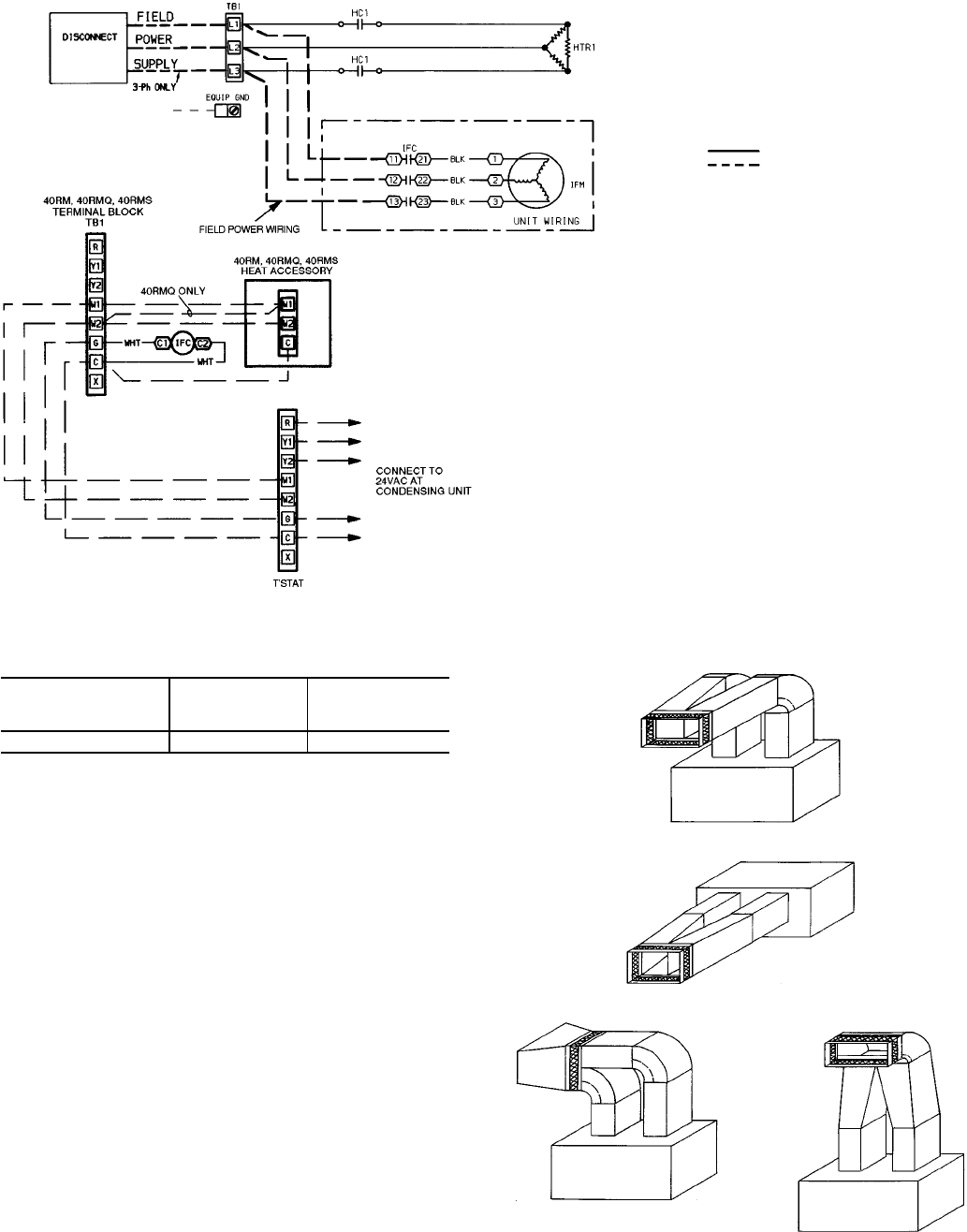

Fig. 14 — Unit Wiring

LEGEND

CB — Circuit Breaker

HC — Heating Contactor

HTR — Electric Heater

IFC — Indoor-Fan Contactor

IFM — Indoor-Fan Motor

NEC — National Electrical Code

TB — Terminal Block

T’STAT — Thermostat

Factory Wiring

Field Control Wiring

NOTE: Use copper conductors only.

Fig. 15 — Typical Fan Discharge Connections

for Multiple Fan Units

596 22

→