8

Mounting Unit on Wall

The units can also be mounted on the wall using the accessory

mounting kit.

Complete Outdoor Refrigerant Piping Connec-

tions

Follow the following general guidelines:

1. Use refrigerant grade field – supplied tubing.

Refer to Table 4 for the correct line sizes.

2. Do not use less than 10 ft (93.05 m) of interconnecting

tubing.

CAUTION

!

UNIT DAMAGE HAZARD

Failure to follow this caution may result in equipment

damage or improper operation.

If any section of pipe is buried, there must be a 6 in. (152.4

mm) vertical rise to the valve connections on the outdoor

unit. If more than the recommended length is buried,

refrigerant may migrate to cooler, buried section during

extended periods of system shutdown. This causes

refrigerant slugging and could possibly damage the

compressor at start--up.

When more than 80 ft (24.4 m) of interconnecting tubing is used,

consult the Duct--Free Split System Long Line Application Guide

for required accessories.

3. Insulate both lines. A minimum of 1/2 inch foam pipe insu-

lation is recommended.

4. Run the refrigerant tubes as directly as possible and avoid

unnecessary turns and bends.

5. Suspend refrigerant tubes to avoid damage to insulation or

tubes so they do not transmit vibration to the structure.

6. When passing refrigerant tubes through the wall, seal the

opening so rain and insects do not enter the structure. Leave

some slack in refrigerant tubes between structure and out-

door unit to absorb vibration.

NOTE: A fusible plug is located in unit suction line; do not cap

this plug. If local codes require additional safety devices, install as

directed.

Connection at Outdoor Unit

CAUTION

!

UNIT DAMAGE HAZARD

Failure to follow this caution may result in equipment damage

or improper operation.

To prevent damage to unit or service valves observe the

following:

S A brazing shield MUST be used.

S Wrap service valves with wet cloth or use a heat sink

material.

38HDF Units:

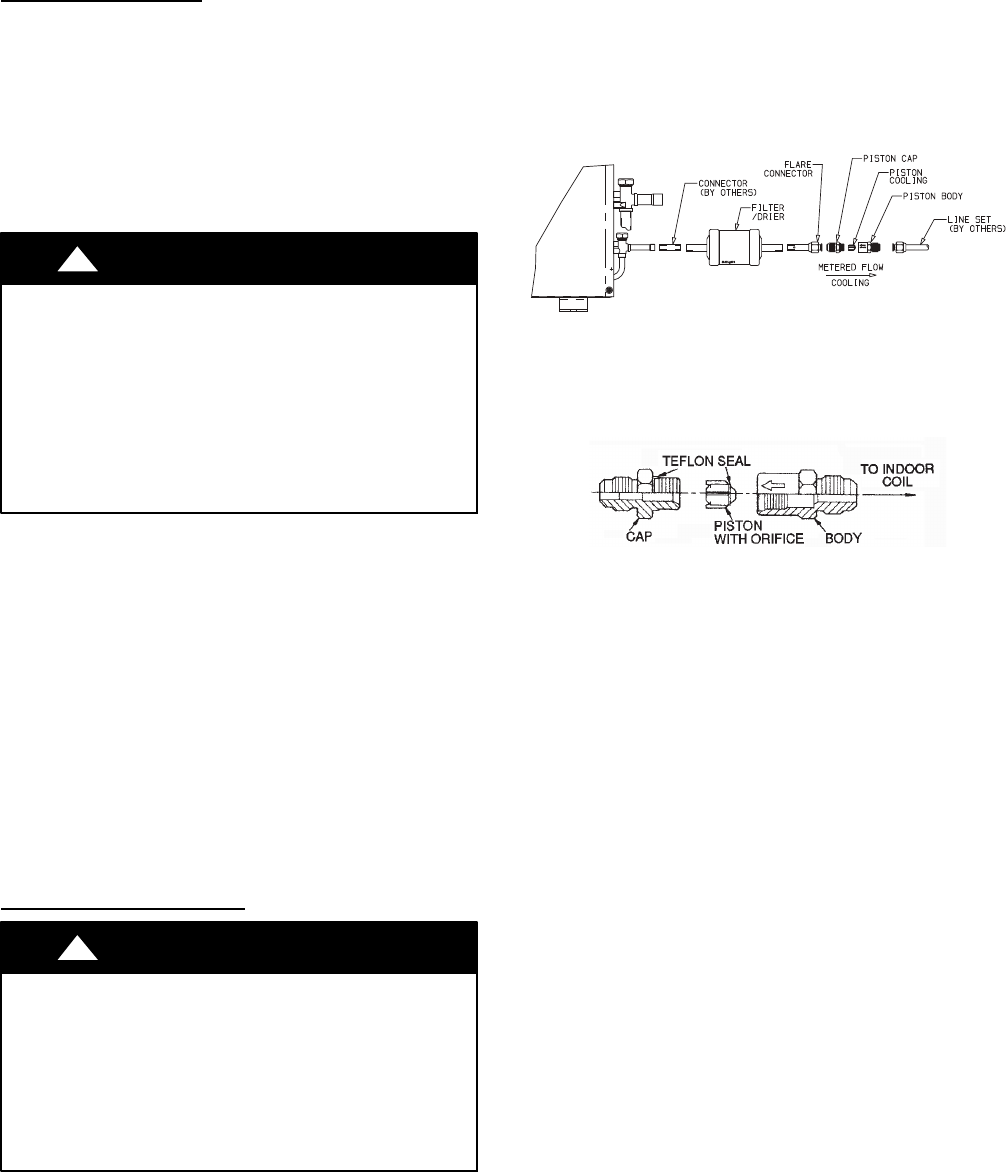

1. Assemble the connector tube to the factory supplied filter

drier by:

a. Braze the field supplied connector to the inlet of the

filter drier (see Fig. 17)

b. Braze the factory supplied flare connector to the outlet

end of the filter drier (see Fig.17)

A09499

Fig. 17 -- 38HDF018--036 Connector Tube Assembly

2. Assemble the Accurator body (see Fig. 18) using the correct

factory supplied piston (refer to Table 7) .

NOTE: Arrow on AccuRater body points in free flow direction, away from the

indoor coil.

A09501

Fig. 18 -- AccuRater (bypass type) Metering Device

Components

3. Attach the complete Accurator assembly to the flare connec-

tion end of the filter drier

4. Braze the completed filter drier/Accurator assembly to the

liquid service valve.

5. Connect the field supplied line set to the filter drier/Accura-

tor assembly and the suction valve. A sweat connection is

required at the suction valve and flare connection is required

for the mixed phase line.

6. Insulate any exposed areas between the line set and the li-

quid valve.