11

Install Fan Motor — For field installation of motors, be

sure electrical junction box is toward the center of the unit.

This is necessary for drive and belts to be properly tightened.

Use smallest slots in motor mounting base that will accommo-

date motor and allow minimum overhang (Fig. 13). Be sure

that motor holddown bolts are tight on field-installed motor.

JUNCTION BOX CONDENSATE PREVENTION — When

air handlers are installed outdoors in a high humidity environ-

ment or indoors where the apparatus room is used as a fresh air

plenum, precautions must be taken to prevent condensation

from forming inside the junction box of the internally mounted

motor.

Standard installation practice is to mount the motor starter

or fused disconnect box adjacent to the air handler and enclose

the power wiring to the motor in flexible conduit.

The sheet metal housing of the disconnect switch or motor

starter is not airtight (even when a box meeting NEMA

[National Electrical Manufacturers Association] IV standards

is used). Thus, warm moist air can migrate through the flexible

conduit to the junction box on the motor. With the motor

located inside the unit, the motor temperature is that of the cool

supply air; thus, condensate can form inside the junction box

and, possibly, on the live terminal lugs.

To prevent the moist air from migrating through the conduit

to the motor, seal the power wires inside the flexible conduit at

the motor starter or fused disconnect.

Use a nonconductive, nonhardening sealant. Permagum

(manufactured by Schnee Morehead) or sealing compound,

thumb grade (manufactured by Calgon), are acceptable

materials.

POWER KNOCKOUTS — Panels are not provided with

knockouts for the fan motor power wiring. Openings must be

drilled or punched in the exterior panels of the unit. It is recom-

mended that power wiring be routed through the discharge

panel whenever possible, as this panel is rarely removed for

service access.

Install Sheaves on Motor and Fan Shafts —

Factory-supplied drives are prealigned and tensioned, however,

Carrier recommends that you check the belt tension and align-

ment before starting the unit. Always check the drive align-

ment after adjusting belt tension.

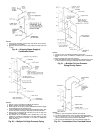

JACKSHAFT CRANKARM

ANTIROTATION STRAP

INSTALLED (ACTUATOR

NOT SHOWN FOR

CLARITY)

IGV ACTUATOR

CONNECTING ROD

ANTIROTATION

STRAP

INLET GUIDE

VANES (IGV)

IGV

JACKSHAFT

Fig. 11 — IGV Actuator Bracket Installation

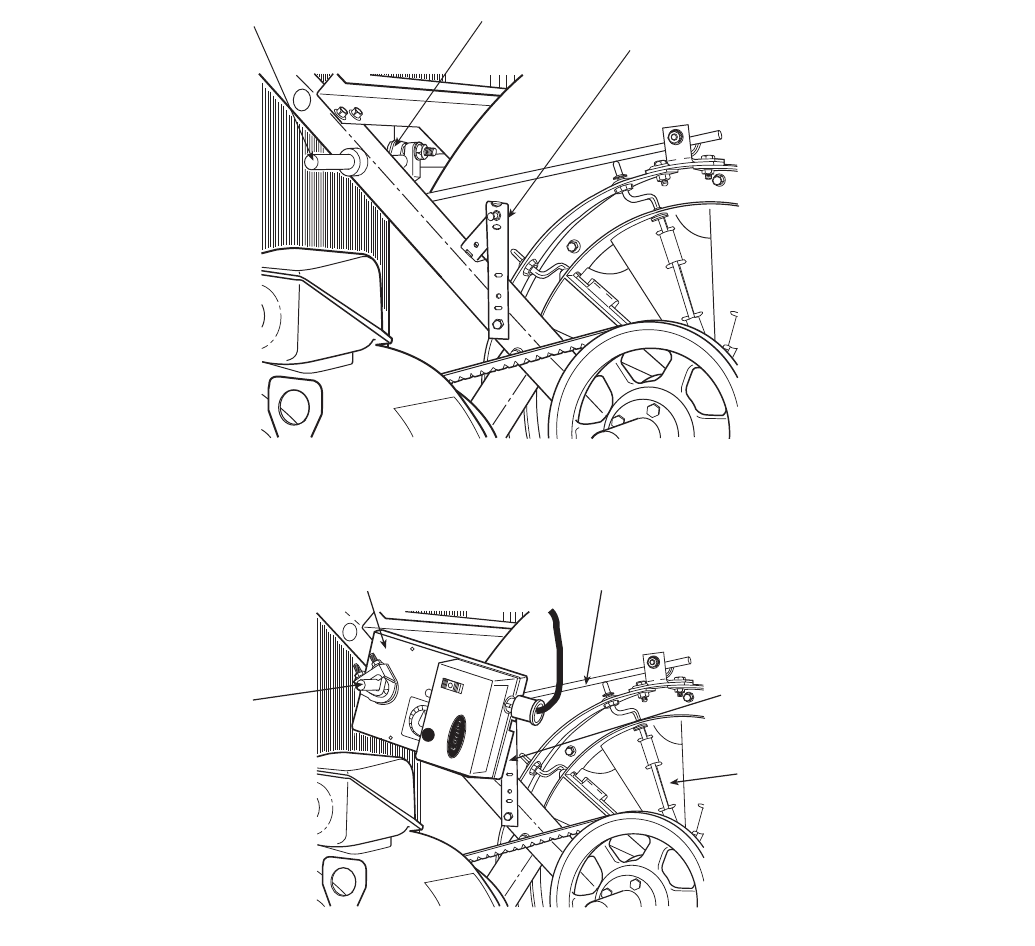

Fig. 12 — IGV Actuator Mounting