NOTE: A backup wrench on the hex part of the suction valve

fitting is required while tightening.

The tube end must stay bottomed in the service valve during

final assembly to ensure proper seating, sealing, and rigidity.

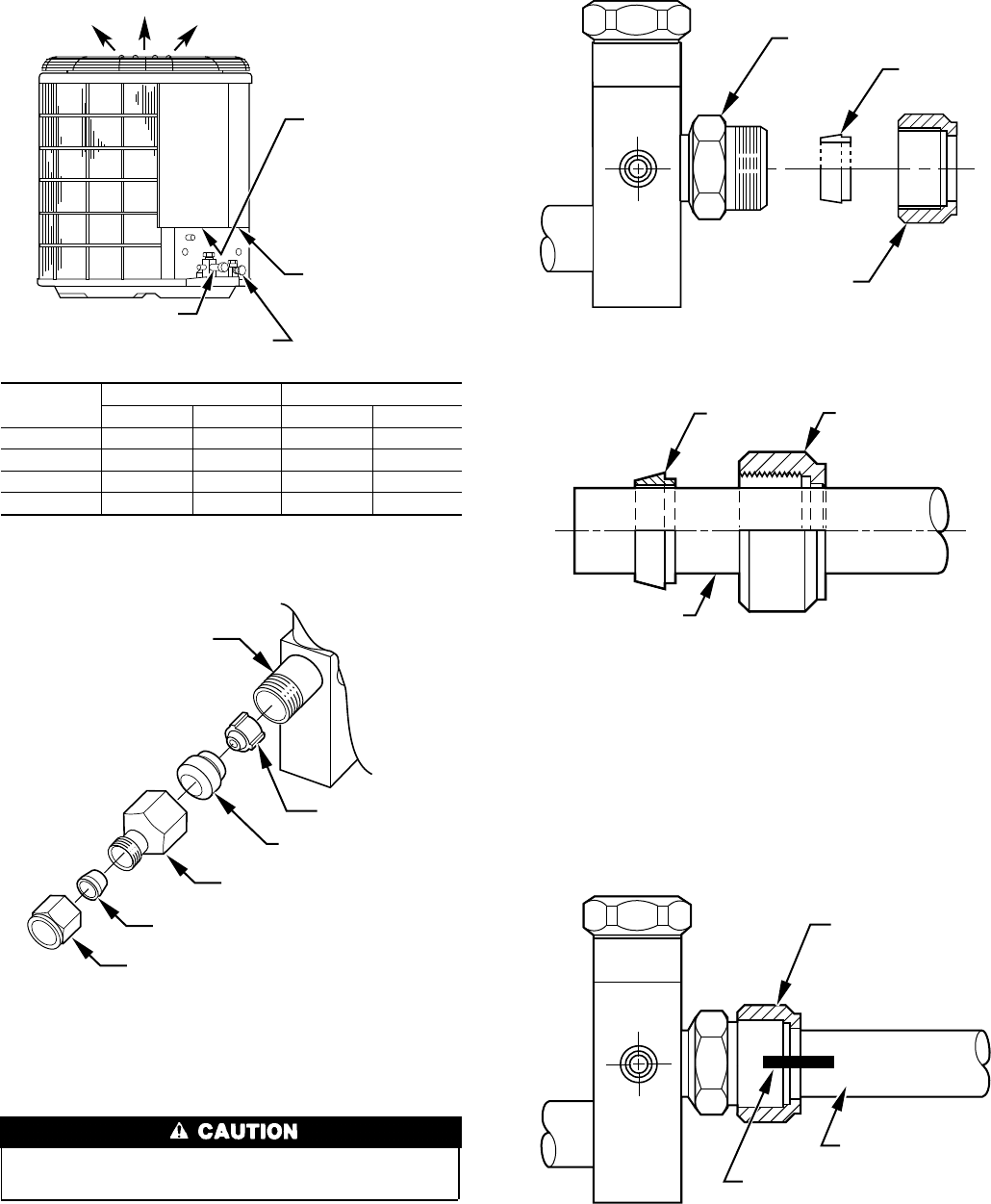

MECHANICAL FITTING REPAIR

To replace damaged ferrule or tubing, proceed as follows.

1. Attach gages to service valves.

2. Close liquid service valve and operate unit in cooling mode to

pump refrigerant charge into condenser coil.

3. When suction pressure reaches 5 psig, shut unit off. Do not

operate unit in a vacuum.

4. Close suction service valve and recover refrigerant in tubing.

5. Back-off locknut and ferrule onto tube.

6. Remove damaged part of tubing using tubing cutter. Repeat

installation procedure previously outlined using new ferrule.

7. Evacuate tubing set and indoor coil. Check for leaks.

8. Open service valves or recharge unit. Check refrigerant

charge.

Fig. 2—Refrigerant Tube Dimensions/Connections

UNIT SIZE

LIQUID TUBE VAPOR TUBE

Conn Dia Tube Dia Conn Dia Tube Dia

018, 024 3/8 3/8 5/8 5/8

030, 036 3/8 3/8 3/4 3/4

042, 048 3/8 3/8 7/8 7/8

060 3/8 3/8 7/8 1-1/8

Tube diameters are for lengths up to 50 ft. For tubing lengths greater than 50

ft, consult your local distributor.

A93578

LIQUID LINE CONN

FIELD CONTROL

SUPPLY CONN

7

⁄

8

″ DIA HOLE

FIELD POWER

SUPPLY CONN

7

⁄

8

″ DIA HOLE WITH

1

1

⁄

8

″ DIA KNOCKOUT

AND

1

3

⁄

8

″ DIA

KNOCKOUT

AIR DISCHARGE

SUCTION LINE CONN

Fig. 3—Liquid Service Valve Mechanical Fitting

Assembly (38YCP Model)

A94030

PISTON BODY

PISTON

PISTON RETAINER

LOCK NUT

LIQUID SERVICE

VALVE ADAPTER

FERRULE

Fig. 4—Suction Service Valve with Mechanical

Adapter (38YCP Model)

A92120

VALVE FITTING

FERRULE

LOCK NUT

Fig. 5—Lock Nut/Ferrule Positioning

A92121

FERRULE LOCK NUT

TUBING

Fig. 6—Proper Marking of Valve Assembly

A92122

LOCK NUT

MARK ON LOCK NUT

AND TUBE

TUBING

2