30RA/30RH

GB - 7

ENGLISH

Water connections

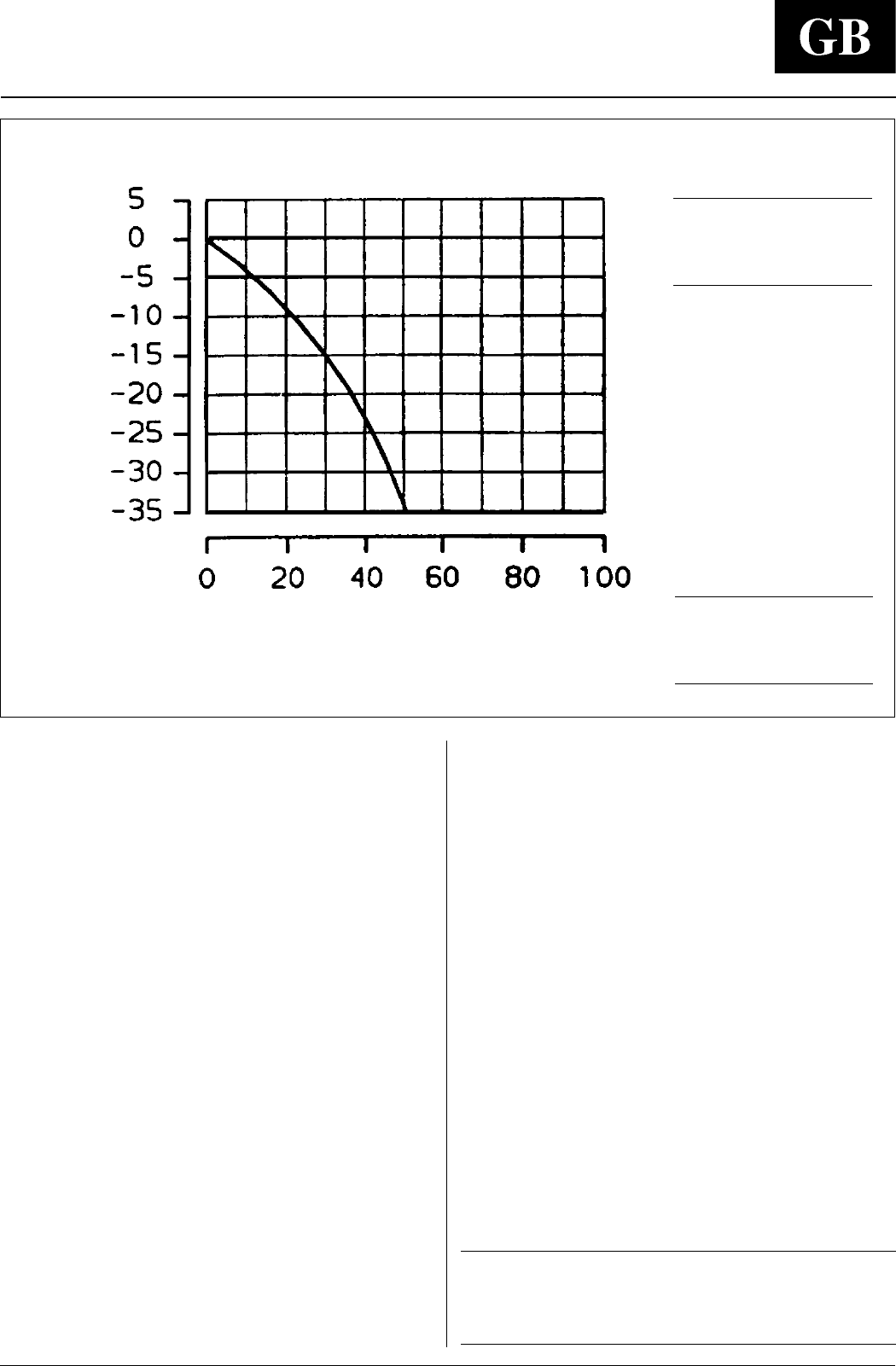

Ethylene glycol curve

Freezing temperature of water- ethylene glycol mixture

°

C

Weight concentration of ethylene glycol in water %

Make the plate heat exchanger hydraulic connections with the

necessary components, using material which will guarantee that

the screwed joints are leakproof.

The typical hydraulic circuit diagram shows a typical water circuit

installation in an air conditioning system.

For an application with a water circuit, the following

recommendations must be taken into account:

1. The pump must be fitted immediately before of the heat

exchanger and after the connection to the system return (unit

without hydronic module).

2. It is advisable to install shut-off valves to allow isolation of the

most important circuit components, as well as the heat

exchanger itself.

These valves (ball, globe or butterfly valves) should produce a

minimum loss of charge when they are open.

3. Provide unit and system drains and vents at the lowest system

point.

4. Install purges in the higher sections of the installation.

5. Pressure ports and pressure gauges should be installed

upstream and downstream of the water pump (unit without

hydronic module).

6. Thermometers should be installed in the unit water inlet and

outlet.

7. All piping must be adequately insulated and supported.

Installation of the following components is obligatory:

1. A flow switch should be installed in a straight horizontal stretch

with a length of at least five times the line diameter on either

side.

The flow switch must be positioned in the exchanger inlet pipe.

It must be electrically connected in accordance with the wiring

diagram (only unit without hydronic module).

If this is not possible, the installation should incorporate a

protection device which is activated when there is no water

circulating in the heat exchanger.

2.The presence of particles in the water can lead to obstructions

in the heat exchanger.

It is therefore necessary to protect the heat exchanger inlet with

an extractable mesh filter.

The filter mesh gauge must be at least 10 mesh/cm

2

.

The standard supply of the unit with hydronic module includes a

mesh filter to be fitted during installation.

3.After assembling the system, or repairing the circuit, the whole

system must be thoroughly cleaned with special attention paid

to the state of the filters.

4.Pump flow rate control is made through a flow control valve

supplied with the unit with hydronic module, which must be

installed on the delivery pipe during installation.

5.In case of water refrigeration at temperatures lower than 5°C, or

if the unit is installed in areas where temperatures drop below

0°C, water must be mixed with a proper quantity of ethylene

glycol (see the curve above).

Use the curve to determine the correct ethylene glycol

concentration for the temperature.

Frost protection

The plate heat exchanger and the water connections of the

hydronic module pump may be damaged in spite of the anti-freeze

protection system these units are fitted with.

Frost protection of the plate heat exchanger and of the circuit

inside the hydronic module is always guaranteed down to -10°C

by the electric heaters that are automatically activated if needed.

The power supply to the electric heaters of the plate heat

exchanger and to the internal circuit of the hydronic module must

never be interrupted.

IMPORTANT:

Both the appliance main switch (Q1) and the auxiliary

protection switch for the electric heaters (QF101) must

always be in the closed position (the positions of Q1 and

QF101 are indicated in the wiring diagram).

CAUTION:

Using water with glycol may

make it necessary to change the

configuration of the control

system.

ATTENTION:

The pump leakproof

components are not suitable

for use with propylene

glycol.