63

5. tightness of joints. Remove all accumulations of

soot with wire brush and vacuum

Remove all obstructions. Replace all deteriorated parts

and support properly. Seal all joints.

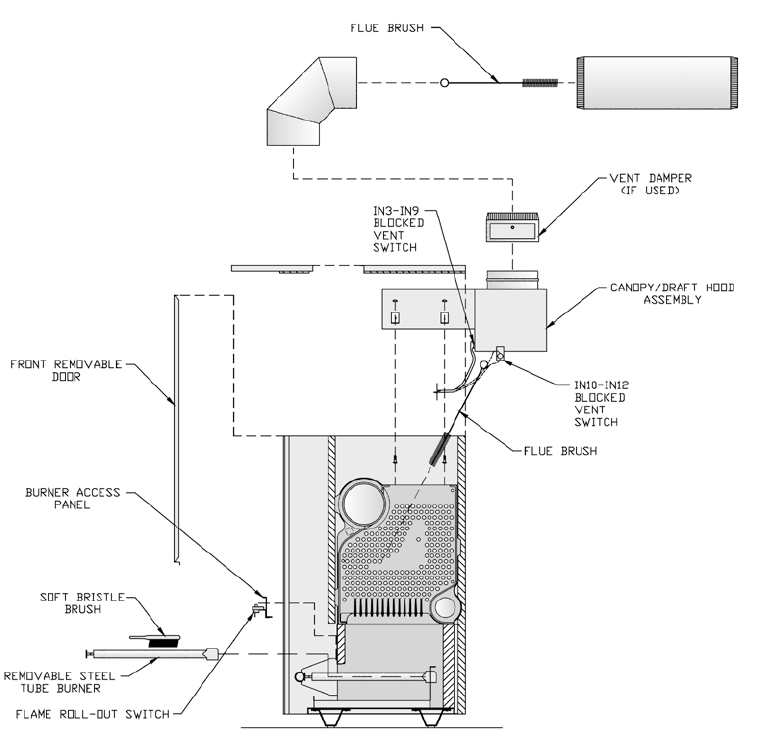

E. Clean Boiler Flueways.

1. Shut down gas boiler in accordance with lighting/

operating instructions attached to inside of Front

Removable Door. See Figure 45.

2. Remove Burner Access Panel and Burners. See

Paragraph F. Clean Burners if necessary.

3. Remove Jacket Top Panels.

4. Remove Canopy from top of boiler.

5. Thoroughly clean the ueways with ue brush. See

Figure 58.

6. Clean boiler heating surface accessible from

combustion chamber with straight handle wire

brush. Reinstall burners and connect gas train. See

Paragraphs F & G.

7. Place boiler in operation in accordance with

Lighting or Operating instructions. Test gas line for

leaks in accordance with Section VI: Gas Piping,

Paragraph C.

8. Replace Jacket Front Removable Door.

i. Inspect connecting lines to boiler for

accumulation of mud and scale. Clean as

necessary.

ii. Examine wiring for brittle or worn

insulation and clean electrical contact.

iii. Inspect solder joints on bellows and oat.

Check oat for evidence of collapse. Check

mercury bulb (where applicable) for

mercury separation or discoloration. Do not

attempt to repair mechanisms in eld.

Complete replacement mechanisms,

including gaskets and instructions, are

available from low water cutoff

manufacturer.

c. Five (5) Years or 100,000 switch cycles. Replace

switch and oat mechanisms.

C. Water Feeder and Additional Low Water Cutoff.

Refer to manufacturer's instructions.

D. Vent System. Check annually for:

1. obstructions

2. accumulations of soot

3. deterioration of vent pipe or vent accessories due to

condensation or other reasons

4. proper support—no sags, particularly in horizontal

runs

Figure 58: Boiler Flueway Cleaning