16

V. Piping and Trim

A. Design and install boiler and system piping to prevent

oxygen contamination of boiler water. Sources of

oxygen contamination are system leaks requiring

addition of makeup water, ttings, and oxygen

permeable materials in distribution system. Eliminate

oxygen contamination by repairing system leaks,

repairing ttings, using nonpermeable materials in

distribution system, and eliminating open tanks in

system, or isolating boiler from system with heat

exchanger.

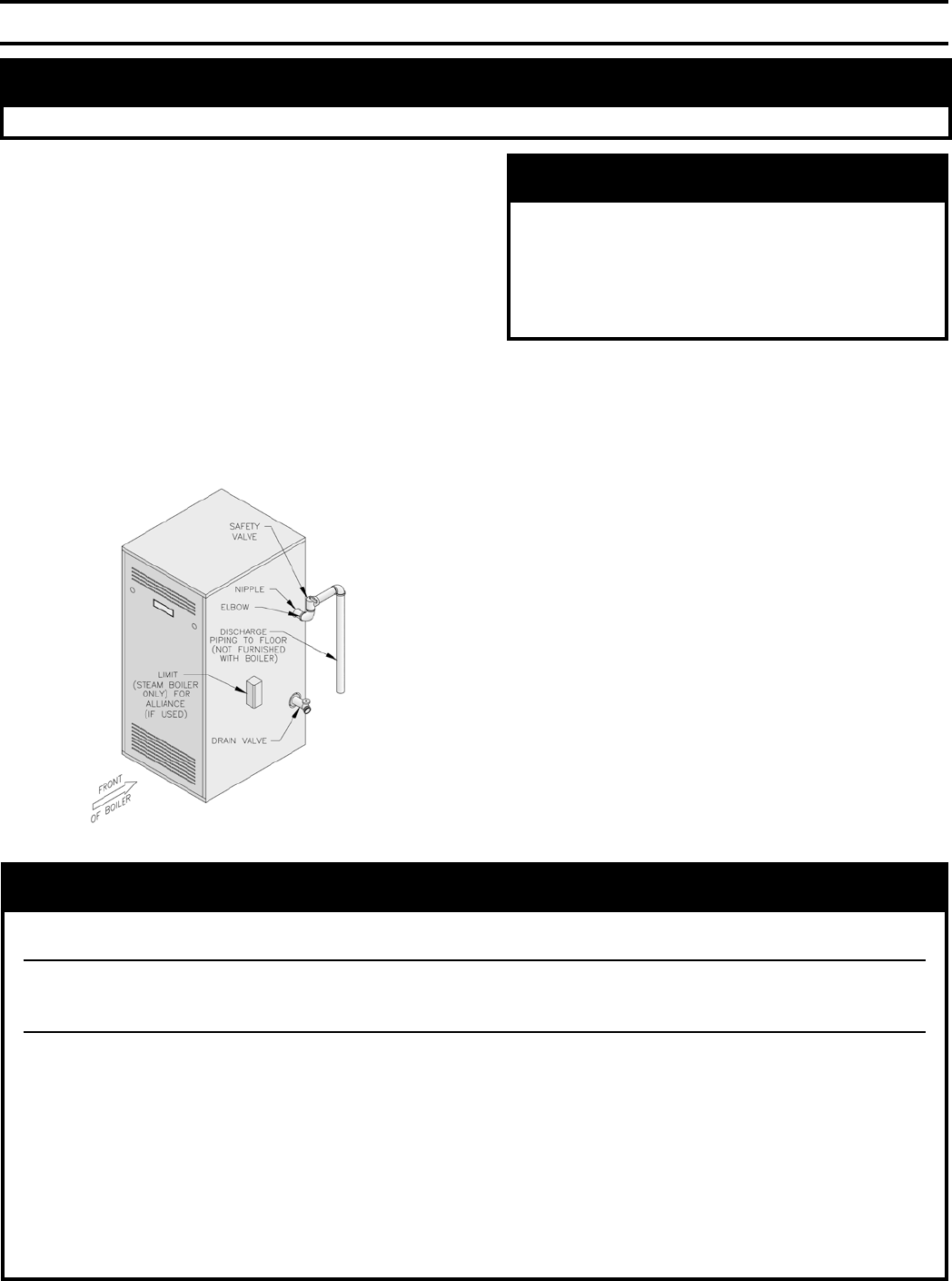

B. Install Safety (Relief) Valve in Tapping "E" (¾ NPT).

See Figure 23. Use ¾ NPT x 3" nipple and ¾ NPT

elbow provided. Safety (Relief) Valve must be installed

with spindle in vertical position.

Figure 23: Trim Installation

WARNING

Safety (relief) valve discharge piping must be

piped such that the potential of severe burns

is eliminated. DO NOT pipe in any area where

freezing could occur. DO NOT install any shut-off

valves, plugs or caps. Consult Local Codes for

proper discharge piping arrangement.

C. Install Drain Valve in Tapping "F" (2 NPT bushed to

¾ NPT). See Figure 23.

D. Connect supply and return piping to heating system.

Maintain minimum ½ inch clearance from combustible

materials.

1. For STEAM HEATING see Figure 24. Consult

I=B=R Installation and Piping Guides.

2. For HOT WATER HEATING with Circulator

(forced) see Figure 25 and 25A. Consult I=B=R

Installation and Piping Guides.

3. If boiler is used in connection with refrigeration

systems, boiler must be installed with chilled

medium piped in parallel with heating boiler using

appropriate valves to prevent the chilled medium

from entering the boiler. See Figure 26. Also

consult I=B=R Installation and Piping Guides.

4. If boiler is connected to heating coils located in air

handling units where they may be exposed to

refrigerated air, boiler piping must be equipped with

ow control valves to prevent gravity circulation of

boiler water during cooling system operation.

WARNING

Failure to properly pipe boiler may result in improper operation and damage to boiler or structure.

NOTICE

Do not use softened water in steam boilers. Accelerated boiler corrosion will result. Tie in fresh water

supply to the boiler upstream of a water softener.

Oxygen contamination of boiler water will cause corrosion of iron and steel boiler components, and

can lead to boiler failure. Burnham's Standard Warranty does not cover problems caused by oxygen

contamination of boiler water or scale (lime) build-up caused by frequent addition of water.

Before using copper for steam piping, consider the following characteristics of copper piping:

1) high coefcient of thermal expansion can induce mechanical stresses and cause expansion/

contraction noises if not accounted for in the piping system design and installation,

2) high heat transfer rate (heat loss) of uninsulated copper piping must be included in the normal

piping and pickup factors used to size the boiler,

3) soldering or brazing pastes and uxes that end up in the system can cause poor heat transfer,

surging, an unsteady water line and wet steam if not thoroughly removed during the boil out

procedure and,

4) galvanic corrosion of the adjoining metal may occur due to dissimilar metals in certain water

chemistries if dielectric unions are not used.