53

C.

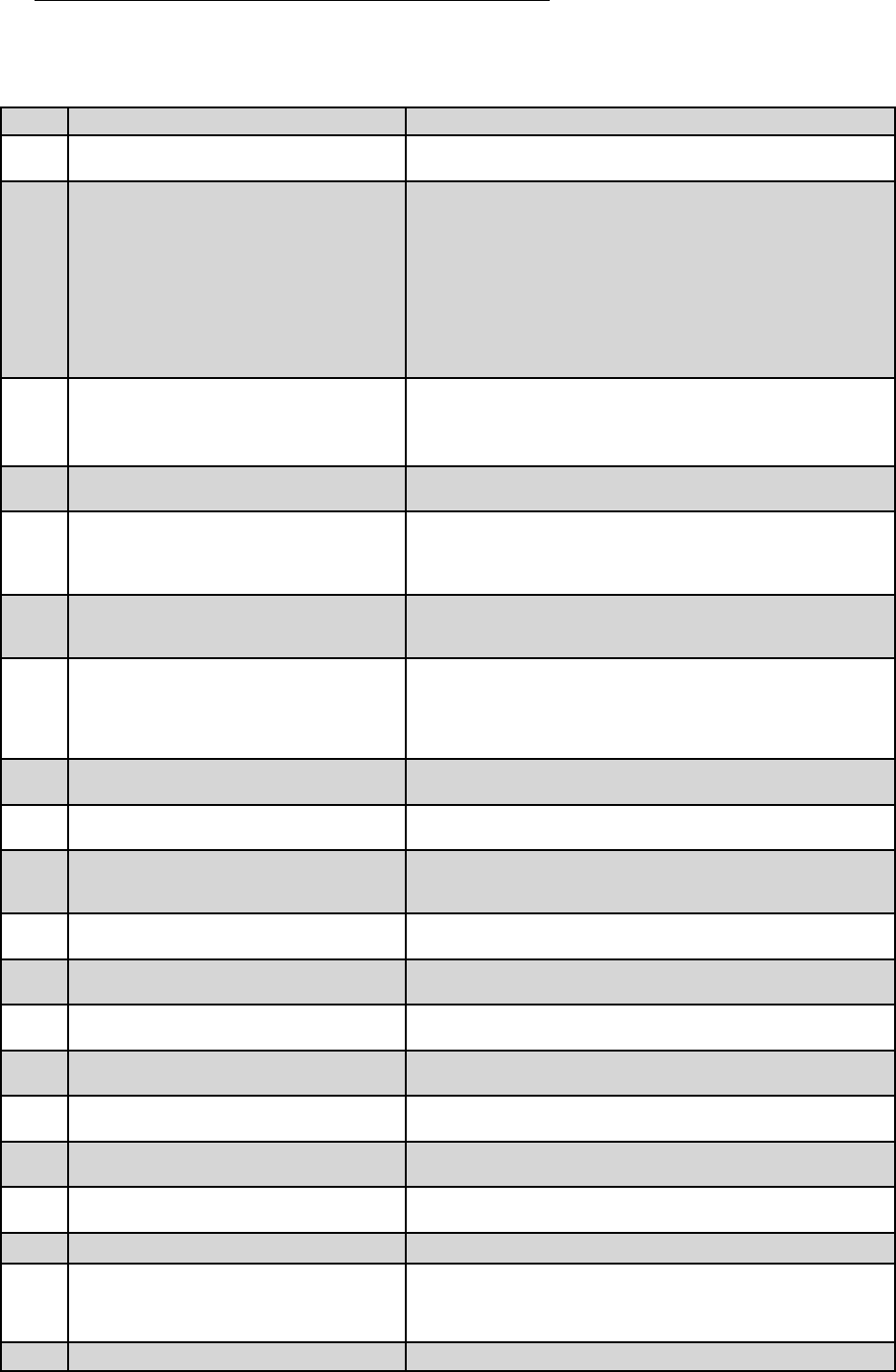

CODE CONDITION POSSIBLE CAUSES

E 00

A ame signal was present when there should

be no ame.

• Defective gas valve - make sure inlet pressure is below maximum

on rating plate before replacing valve.

E 02 Flame failure after 5 tries to restart

• No gas pressure

• Gas pressure under minimum value shown on rating plate

• Gas line not completely purged of air

• Defective Electrode

• Loose burner ground connection

• Defective Ignition Cable

• Loose or defective gas valve harness

• Defective gas valve (check for 24 VDC at harness during trial for

ignition before replacing valve)

• Air-fuel mixture out of adjustment - consult factory

E 03 Gas valve error

• Loose or defective gas valve harness. Check electrical

connections.

• Defective gas valve (check for 24 VDC at harness during trial for

ignition before replacing valve)

E 04 Power failure occurred after lockout

• Some other error on this list occurred and power to the boiler was

then interrupted. Reset control and see if hard lockout reoccurs.

E 05

E 06

E 07

E 11

Internal control failure • Reset the control. If problem reoccurs, replace the MCBA.

E 12 Low water cut-off circuit open

• If yellow light on LWCO is on, system is low on water

• If neither yellow nor green light is on, check LWCO harness and

check for 24VAC across AT140 transformer

E 13

E 14

E 15

E 16

E 17

Internal control failure • Reset the control. If problem reoccurs, replace the MCBA.

E 18

MCBA supply sensor detected temperatures in

excess of 200°F for an extended period of time

• See possible causes for “b18” error. Also, check safety limit for

proper operation.

E 19

MCBA return sensor detected temperatures in

excess of 200°F for an extended period of time

• See possible causes for “b19” error.

E 28

Blower is not running when it should or fan

speed signal not being detected by MCBA

• Loose connection in 120 VAC fan wiring

• Loose or miswired fan speed harness

• Defective fan

E 29 Blower fan speed has not returned to zero rpm

• Miswired fan speed harness

• Defective fan

E 31 Shorted supply temperature sensor

• Shorted or miswired supply sensor wiring

• Defective supply sensor

E 32 Shorted return temperature sensor

• Shorted or miswired return sensor wiring

• Defective return sensor

E 35 Flue gas temperature sensor short circuit

• Shorted or miswired ue temp sensor wiring

• Defective ue temp sensor

E 36 Supply water temperature sensor circuit open

• Loose or miswired supply sensor wiring

• Defective supply sensor

E 37 Return water temperature sensor circuit open

• Loose or miswired return sensor wiring

• Defective return sensor

E 40 Flue gas temperature sensor circuit open

• Loose or miswired ue temp sensor wiring

• Defective ue temp sensor

E 44 Internal control failure • Reset the control. If problem reoccurs, replace the MCBA.

E 52 Flue gas temperature over 230°F

• Heat exchanger needs to be cleaned

• Boiler over-red

• Air-fuel mixture out of adjustment - consult factory

E 60 Internal control failure • Reset the control. If problem reoccurs, replace the MCBA.