17

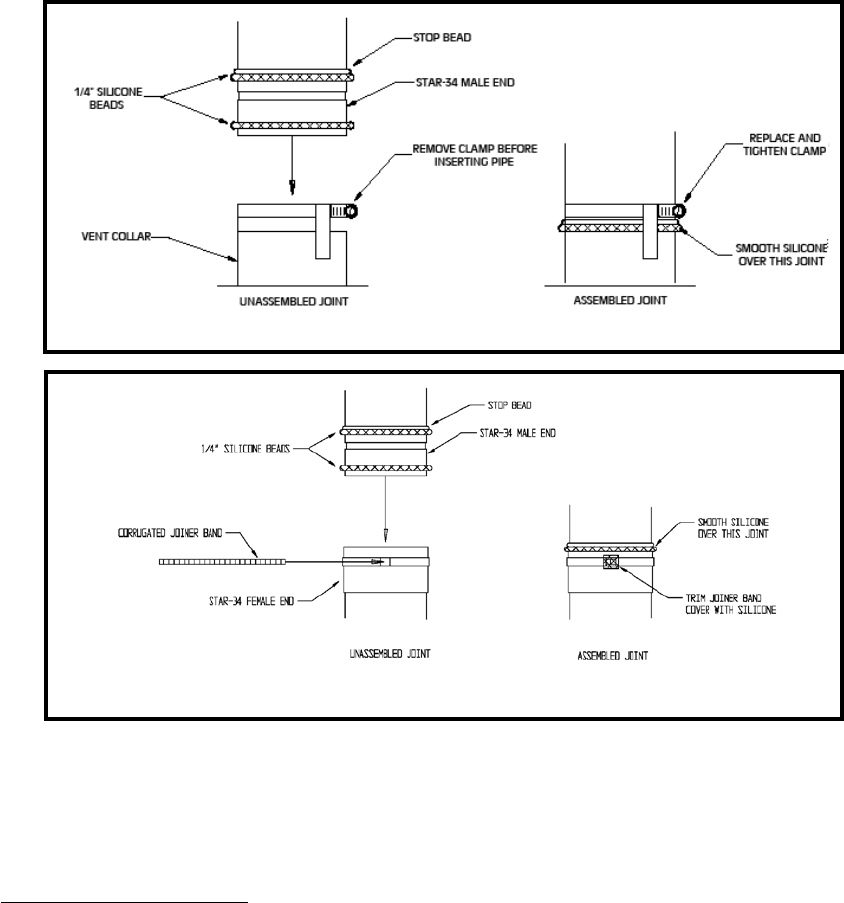

Figure 6.7b: Star-34 Connections

l) Cuttheexcessjoinerbandsothatitlaysatinthebeadedchannel(Fig6.7b).

m)Filltheinletofthebeadedchannelwithsilicone.Smooththesiliconeoverthechannelinletaswellasthe

siliconebetweenthefemaleendandthestopbeadofthemaleend(Fig6.7b).

n) RepeatSteps(h)–(m)fortheremainingStar-34components.

p) Allowthesiliconetocureperthesiliconemanufacturer’sinstructionsbeforeoperatingtheboiler.

5) AssemblyofZ-FlexZ-VentIII:

a) General Notes:

• Non-expandedendsofSVESeriesIIIpipingsectionsmaybecutusingaviationsnipsora24threadperinch

hacksaw.Fileorsandthecutendsmoothbeforeassembling.Seethefollowinginstructions.

• Supporthorizontalpipingsectionsatintervalsof48”orless.

• VerticalventingsystemsmustbesupportedbyatleastoneZ-Flexrestop.Anadditionalvertical

supportisrequiredafteranyoffsetandasrequiredbytheZ-VentIIIinstallationinstructions.

b) Startassemblyoftheventsystemattheboiler.RemovethehoseclampshippedontheCHGventcollar.

Bendthethreehoseclamptabsonthiscollaroutwardslightly.

c) Cleantheexteriorofthemaleendoftherstpieceofpipeandtheinsideoftheventcollarontheboiler.

Removedirt,grease,andmoisturefromthesurfacestobesealed.Drysurfacesorallowtodrythoroughly.

d) Onthemaleendofthepipe,applya¼”widebeadofhightemperaturesiliconeapproximately½inchfrom the

maleendofthepipe.Apply¼”beadsofsiliconealongbothsidesofthelongitudinalseam(Fig.6.8).

e) Insertthemaleendofthepipeintotheboilerventcollaruntilitbottomsout.

f) Applyanadditionalbeadofsiliconeovertheoutsideofthejointandsmoothout.

g) Replaceandtightentheclampontheventcollar.

h) ThefemaleendofeachZ-VentIIIcomponenthasasiliconesealinggasket.Examineallventcomponents

toinsurethatthegasketintegrityhasremainedduringshipping.Gasketsmustbeintheproperpositionor

uegascouldleakresultingincarbonmonoxidepoisoning.

Figure 6.7a: Star-34 Connection to Vent Collar