—7—

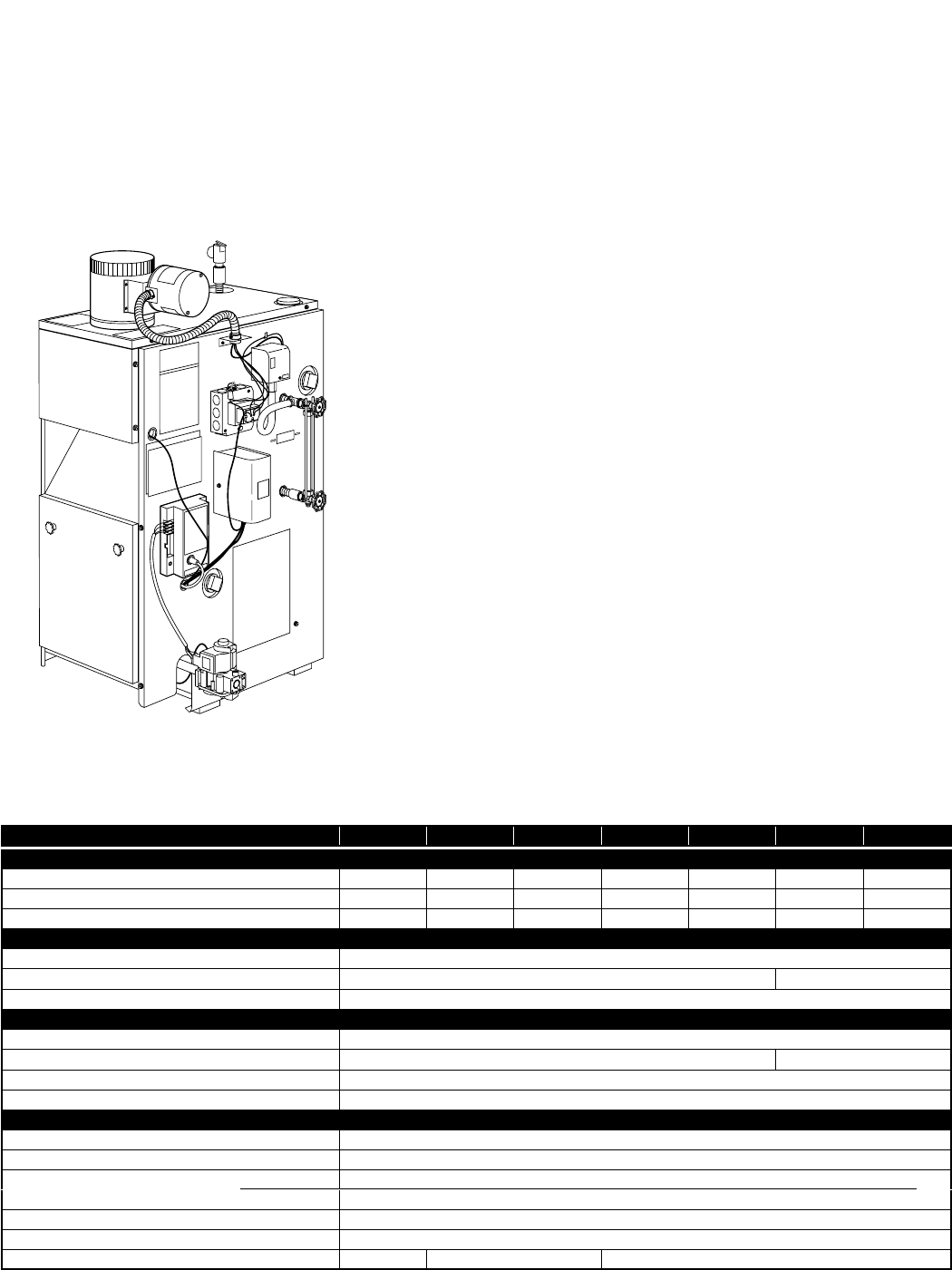

SPECIFICATIONS

*

Factory authorized and listed, field installed.

UNIT SIZE

075 112 150 187 225 262 299

GENERAL DATA

Sections—Fine Grain Cast Iron No. 3456789

Burners—Stainless/Titanium Alloy No. 2345678

Burners—Orifice Drill Size Natural 34 34 34 34 34 34 34

GAS CONTROLS — STANDING PILOT (BS1)

Gas Valve Honeywell

Inlet Size

In.

1/2 FPT 3/4 FPT

Pilot Assembly Honeywell

GAS CONTROLS — INTERMITTENT PILOT (BS2)

Gas Valve Honeywell

Inlet Size

In.

1/2 FPT 3/4 FPT

Pilot Assembly Honeywell

Spark Generator Honeywell/UTEC

CONTROLS

Low-Water Cutoff McDonnell Miller

Pressuretrol Psig 0—15

Pressure Relief Valve Setting 15 Psig

Capacity 400 lb/hr

Pressure Retard Gage Range Psig 0–30

Drain Cock In. 3/4

Vent Damper

*

In. 5 6 7

Models BS1 and BS2 Gas-Fired Steam Boilers provide fast

heat quietly and economically to assure the finest in hydronic

heating.

These boilers provide quality design in a small, compact unit

easily installed in a basement, garage, or utility room. They

can be installed on a combustible floor when an optional

combustible floor base is used.

The model BS1 and BS2 design is CSA and A.G.A. certified

for use with natural and is convertible to propane gas with

accessory kit.

FEATURES

RANGE OF CAPACITIES

—Sizes 75,000 through 299,000 Btuh

input are available.

COMPLETELY PACKAGED

—Each boiler is completely assem-

bled, including all controls (except room thermostat). All necessary

wiring is factory installed. The boiler is ready for gas, water, room

thermostat, and electrical connections as shipped.

THERMAL-PIN, CAST-IRON SECTIONS

—These sections speed

heat transfer from the flue gases to the boiler water, with faster ther-

mostat response, providing greater comfort and economy. Max-

imum heat is produced at a lower level on the thermal-pin sections,

leading to peak efficiency.

TITANIUM COMPOSITE BURNERS

—Provide quiet operation,

corrosion resistance and improved combustion efficiency. Propane

convertible – with accessory kit.

CONTROLS

—An automatic gas valve and continuous pilot or

intermittent pilot provide quiet, dependable operation of the

burners. Factory-installed safety components assure protection

against overheating, pressure buildup, and low-water operation.

INSULATED CASING

—The casing is fully insulated with fiber-

glass for maximum operating efficiency and economy.

AUTOMATIC VENT DAMPER

—The Model BS1 and BS2 is

designed with automatic vent damper to recover chimney loss

during off cycle.

SECTIONS TESTED

—Each section is hydrostatically tested to

50 psig. Individual sections are tested to 125 psig at factory.

Assembled sections are tested to 75 psig at the factory.

Maximum allowable working pressure is 50 psig. The

maximum allowable pressure is 15 psig for steam boilers.

INTERGRAL DRAFT

—These boilers incorporate an integral draft

system to simplify installation. No external draft diverter is needed.

WARRANTY

—The cast-iron sections are covered by a non-

prorated 12-year warranty on the entire assembly. Vent damper

covered by 5-year warranty. All other parts are covered by a 1-year

limited warranty.

MODELS BS1 and BS2