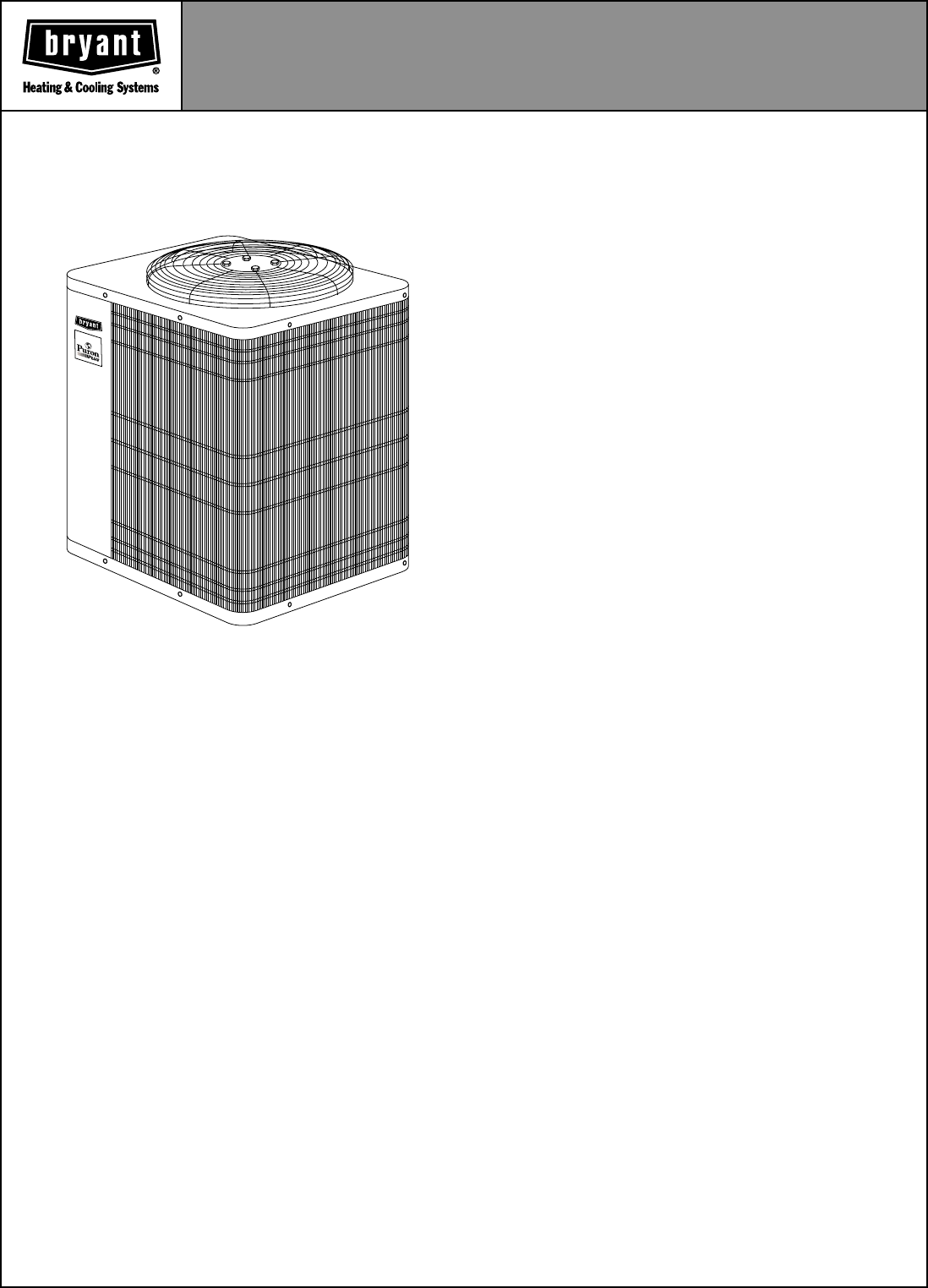

Form No. PDS 598B.24.4

TWO-SPEED PURON® PLUS™

ELECTRIC AIR CONDITIONER

598B (60 HZ)

Sizes 024, 036, 048, and 060

•

T

W

O

-

S

P

E

E

D

•

™

Model 598B Air Conditioners incorporate innovative 2-speed

compressor technology with Puron®, the refrigerant of the

future, to provide quiet, efficient cooling performance. Built into

these units are features most desired by consumers today.

SEER ratings of up to 16.5 can be reached when combined with

specific Bryant equipment. All models are listed with UL, c-UL,

ARI, CEC, and CSA-EEV. The 598B meets the Energy Star

®

guidelines for energy efficiency.

FEATURES

COIL PROTECTION

—The DuraGuard coil protector, made of a

12 gage coated steel wire grid with vertical 3/8 in. spacing, is

designed to help protect the coil from inclement weather, vandal-

ism, and incidental hits. It provides protection while not restrict-

ing airflow and maintaining ease of coil inspection and cleaning.

ELECTRICAL

—All units are offered in 208/230v single phase.

Simplified field-stripped lead wire connections facilitate ease of

installation.

RANGE OF SIZES

—Available in 4 nominal sizes: 024, 036, 048,

and 060 to meet the needs of residential applications.

WEATHER-PROTECTED CABINET

—Steel is galvanized and

coated with a layer of zinc phosphate. A modified polyester pow-

der coating is then applied and baked on, providing each unit

with a hard, smooth finish that will last for many years.

All screws on the cabinet exterior are ceramic coated for a long-

lasting, rust-resistant, high-quality appearance.

RELIABILITY BY DESIGN

—The coil incorporates copper tub-

ing and enhanced, aluminum fins for optimum heat transfer. Hot

condenser air and sound are discharged vertically and away

from adjacent patio areas and foliage through the AeroMax

opening. A heat pump style basepan is used for easy removal of

water, dirt, and debris.

Auto-reset high- and low-pressure switches continuously moni-

tor system operation.

A compressor crankcase heater, energized at the proper tem-

perature during the compressor off cycle, helps to provide reli-

able starting.

TOTALLY ENCLOSED FAN MOTOR

—Means greater reliability

under adverse weather conditions and dependable performance

for many years. The permanent-split-capacitor type motor was

designed for optimum efficiency. The motor was tested and qual-

ified under extreme conditions to ensure the greatest reliability.

AEROQUIET FAN SYSTEM

—Allows air to move through the unit

more easily which lowers sound levels and improves efficiency.

APPLICATION VERSATILITY

—This unit can be combined with

a wide variety of evaporator coils and fan coils to provide quiet,

dependable comfort. Unit can be installed on a roof or at ground

level on a slab.

EXTERNAL SERVICE VALVES

—Both service valves are brass,

back seating type with sweat connections. Valves are externally

located so refrigerant connections can be made quickly and eas-

ily. Each valve has a service port for ease of checking operating

refrigerant pressures.

EASY SERVICEABILITY

—Removal of access panel and con-

trol box cover provides easy access to the compressor and all

electrical controls. Removal of top provides access to fan motor

and coil. A self-diagnostic indicator on the electronic control

board informs the service technician of the failed component.

COMPRESSOR PROTECTION

—Each compressor speed is pro-

tected with internal overloads. An internal pressure relief valve

provides high-pressure protection to the refrigerant system.

STANDARD FEATURES

—An electronic control eliminates

excessive wiring. A compressor sound hood and discharge muf-

fler provide improved sound levels as well as sound quality.

COMPRESSOR START ASSIST

—Capacitor and relay.

EXPANSION VALVE

—This unit must be installed with a Puron®

TXV on the indoor coil. The FV4 indoor fancoils and the CK5APX

furnace coils come factory equipped with a bi-flow balance port

Puron TXV. When installed in this application, no further change

is required. If any other indoor fancoil or furnace coil is used, an

accessory bi-flow, balance port TXV must be installed. See

accessory list in this publication for correct part number.

LIMITED WARRANTY

—Five-year limited warranty on all parts

with a 10-year limited warranty on the compressor. Refer to war-

ranty certificate for specific details.