(4.) ENH (enhanced) selection provides a 30 sec. cooling &

heat pump on delay with no airflow, plus 150 seconds at 70

percent airflow and no off delay for added comfort. This

will minimize cold blow in heat pump operation and could

enhance system efficiency.

f. CONTINUOUS FAN—SELECT DESIRED FAN SPEED

WHEN THERMOSTAT IS SET ON CONTINUOUS FAN

(1.) LO speed—Factory setting, 50 percent cooling mode

airflow.

(2.) MED speed—Move connector to MED, 65 percent cooling

mode airflow.

(3.) HI speed—Move connector to HI, 100 percent cooling

mode airflow (See Fig. 8, F as indicated).

g. LOW-VOLTAGE CIRCUIT FUSING AND REFERENCE

The low-voltage circuit is fused by a board-mounted 5–amp

automotive fuse placed in series with the transformer SEC2 and

the R circuit. The C circuit of the transformer is referenced to

chassis ground through a printed circuit run at SEC1 connected

to metal standoff marked with ground symbol.

h. BASIC UNIT CONFIGURATION

The following basic configuration of the indoor motor will

provide ARI rated performance of the 683B. This BASIC

CONFIGURATION should be used when the rated ARI perfor-

mance is required.

(1.) HEAT-Factory selected to match heat input size.

(2.) AC/HP Size-Factory selected to match system size, please

verify.

(3.) SYSTEM TYPE-Factory selected on 683B system for

HP-EFF.

(4.) AC/HP CFM ADJUST-Select HIGH for 042 & 048, NOM

for 036 & 060, and LO for 024 & 030.

(5.) ON/OFF DELAY-Factory selected 0/90 profile.

(6.) CONTINUOUS FAN-Select desired fan speed when ther-

mostat is set to continuous fan.

i. COMFORT OPTIONS—SUPER DEHUMIDIFY (See Quick

Reference Guide)

The Super Dehumidify option is possible when this unit is

installed with a field supplied Thermidistat™ control (Super-

Dehumidify does not require an outdoor temperature sensor).

The following configuration is recommended for maximum

cooling/dehumidifying comfort. This configuration will im-

prove the comfort provided by the air conditioning system if

more humidity removal is desired. While providing this im-

proved comfort, the system will operate efficiently, but not at

the published ARI SEER efficiency.

The following system configuration is recommended for maxi-

mum cooling/dehumidifying comfort (See Fig. 8).

(1.) HEAT-Factory selected to match gas heat size of unit

installed.

(2.) AC/HP Size-Factory selected to match system size, please

verify.

(3.) SYSTEM TYPE-Factory selected on 683B system for

HP-EFF.

(4.) AC/HP CFM ADJUST-Select NOM (Lo for 060).

(5.) ON/OFF DELAY-Select ENH profile.

(6.) CONTINUOUS FAN-Select desired fan speed when ther-

mostat is set to continuous fan.

(7.) LOW VOLTAGE CONNECTIONS-Make connections as

shown in ELECTRICAL CONNECTIONS section.

(8.) CONFIGURE THERMIDISTAT™-Follow Thermidis-

tat™ installation instructions for Super Dehumidify opera-

tion.

ACCESSORY INSTALLATION

a. AUXILIARY TERMINALS

The AUX and HUM terminals on the Easy Select™ Board are

tied directly to the G terminal, and provide a 24-v. signal

whenever the G terminal is energized (See Fig. 9). During

Super dehumidify mode, the G signal is not present and the

auxiliary terminals are not energized. If the installation includes

the use of this operating mode, do not use these terminals to

control accessories. See Electronic Air Cleaner and Humidifier

sections for further information.

b. ELECTRONIC AIR CLEANER CONNECTIONS

The AUX1 and AUX2 terminals are not always energized

during blower operations, as described above. When using an

electronic air cleaner with the unit, use Airflow Sensor P/N.

KEAAC0101AAA. The airflow sensor turns on electronic air

cleaner when the blower is operating.

c. HUMIDIFIER / THERMIDISTAT™ CONNECTIONS

Easy Select™ Board terminals HUM1 and HUM2 are provided

for direct connection to the low-voltage control of a humidifier

through a standard Thermidistat™ (See Fig. 9). These terminals

are energized with 24-v. when G thermostat signal is present

(See Fig. 10). Alternately, the 24-v. signal may be sourced from

the W and C on the 9 pin connector. When using a Thermidis-

tat™ Control the 24-v. signal may be sourced directly from the

Thermidistat™ HUM terminal (See Fig. 8, 9 & 10).

d. DEHUMIDIFY CAPABILITY WITH STANDARD

THERMIDISTAT™ CONNECTION

Latent capacities for this unit are better than average systems. If

increased latent capacity is an application requirement, the ICM

board provides connection terminals for use of a Thermidis-

tat™. The unit will detect the Thermidistat™ contacts opening

on increasing humidity and reduce its airflow to approximately

80 percent of nominal cooling mode airflow. This reduction

will increase the system latent capacity until the humidity falls

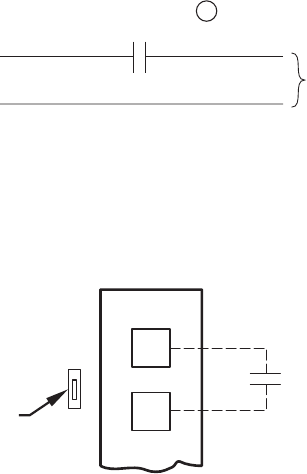

Fig. 9—Humidifier Wiring-683B

C01108

THERMIDISTAT ™

TO HUMIDIFIER

HUMIDIFIER WIRING

HUM 1

(C)

HUM 2

(G)

24-VAC

Fig. 10—Thermidistat™ Wiring for

De-Humidify Mode-683B

C01109

EASY SELECT

BOARD TERMINAL

BLOCK

D

H

J1

R

THERMIDISTAT

JUMPER

—6—