7

90

STEP 1

STEP 2

C

L

O

S

E

STEP 3

OFF

ON

MAIN

A07797

Fig. 7 -- To Shut--off Unit Electric Cooling

MANIFOLD

BURNER

BURNER FLAME

C99021

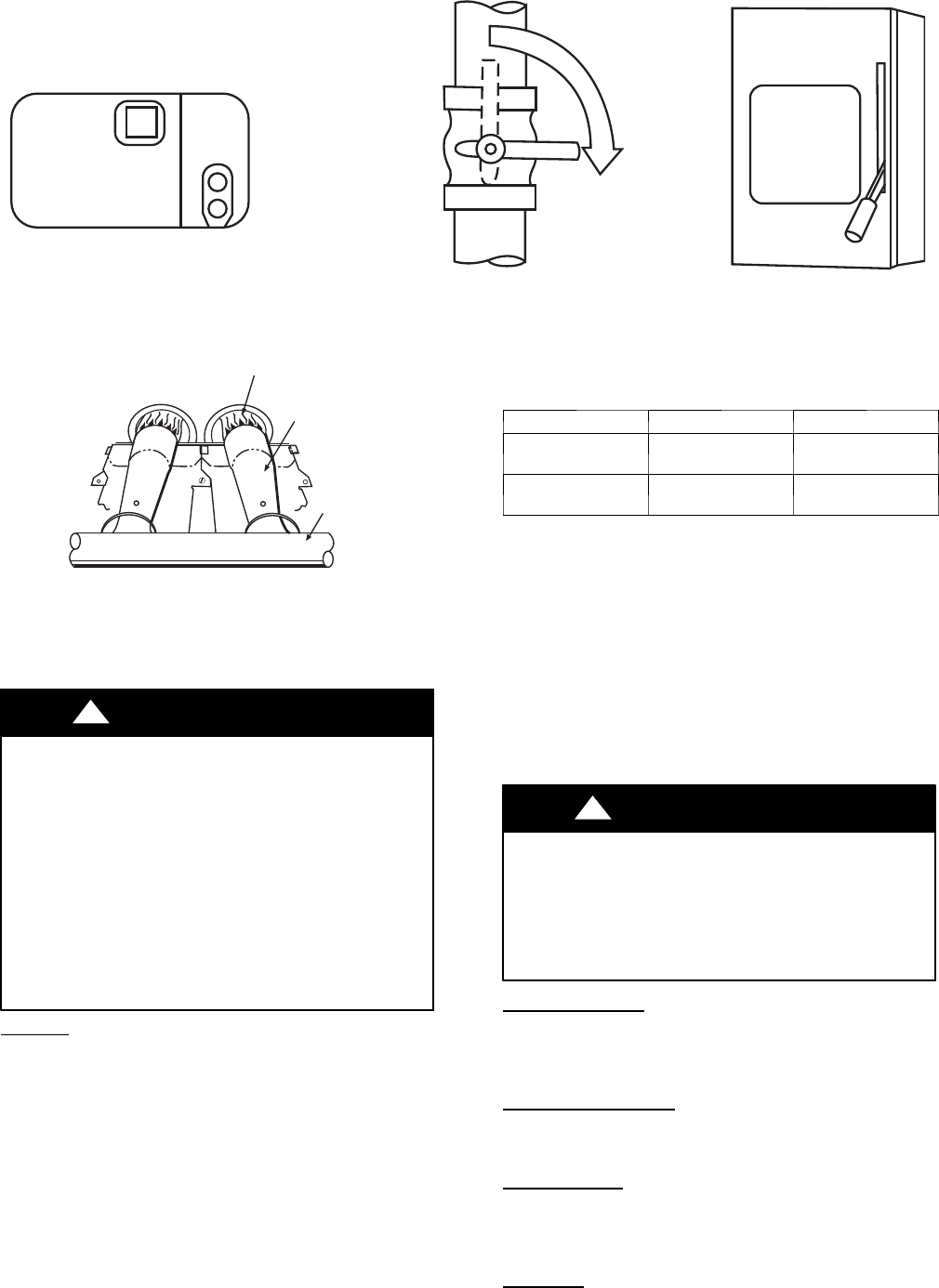

Fig. 8 -- Monoport Burner

Maintenance and Care for the Equipment Owner

Before proceeding with those things you mi ght want to maintain

yourself, please carefully consider the following:

FIRE, EXPLOSION, ELECTRICAL SHOCK AND

CUT HAZARD

Failure to follow this warning could result in personal injury,

death or property damage.

1. TURN OFF ELECTRICAL POWER TO YOUR UNIT

BEFORE SERVICING OR PERFORMING

MAINTENANCE.

2. When removing access panelsorperforming maintenance

functions inside your unit, be aware of sharp sheet metal

parts and screws. Although special care is taken to reduce

sharp edges to a minimum, be extremely careful when

handling parts or reaching into the unit.

!

WARNING

Air Filters

Theair filter(s) should bechecked every 3 or4 weeks and changed

or cleaned whenever it becomes dirty. Dirty filters produce exces-

sivestresson theblowermotorand can causethemotor to overheat

and shut down.

This unit must have air filters in place be fore it can be operated.

Thesefilterscan be located in one of at leasttwo places.In many ap-

plications, the installer will provide return air filter grilles mounted

on the wall orceiling of the conditionedstructure. Intheinstanceof

filtergrilles,the filterscan simply be removedfromthegrille andre-

placed.

Theother typical application is a n accessory filter rack installed in-

side the unit itself. The following information is given to assist in

changing filters us ed in these internal filter racks.

Table 1 indicates the correct filter size for your unit. Refer to Fig. 2

to access filters installed in the accessory filter rack.

Table 1—Air Filters Located Inside Unit

(For Replacement Purposes)

Unit Size Quantity Filter Size in. (mm)

A24---A30 2

12x20x1

(305x508x25)

A36---A60 3

12x24x1

(305x610x25)

To repl ace or inspect filters in accessory filter rack (See Fig. 2) :

1. Remove the filter access panel us ing a 5/ 16--in. nut driver.

2. Removethefilter(s)bypullingitoutoftheunit.Ifthef ilter(s)

is di rty, clean or replace with a new one.

When installing the ne w filter(s), note the direction of the airflow

arrows on the filter frame .

If you have difficulty locating your air filter(s) or have questions

concerning proper filter maintenance, contact your dealer for in-

structions.When replacing filters, a lways usethesamesize andtype

of filter that was supplied originally by the ins taller.

FIRE AND UNIT OPERATION HAZARD

Failure to follow this warning could result in personal injury,

death or property damage.

Never operate your unit without filters in place. An

accumulation of dus tand lint on interna lparts ofyour unitcan

cause loss of efficiency.

!

WARNING

Fans and Fan Motors

Periodically check the condition of fan wheels and housings and

fan--motor shaft bearings. Contact your dealer for the required

annual maintenance.

Indoor and Outdoor

Coils

Cleaning of the coils should only be done by qualified service per-

sonnel. Contact your dealer for the required annual maintenance.

Condensate

Drain

The drain pan and condensate drain line should be checked and

cleaned atthesametimethecooling coilsarecheckedby yourdeal-

er.

Compressor

Allcompressorsarefactoryshippedwithanormalchargeofthecor-

rect type of refrigeration grade oil. A compressor should rarely re-

quire additional oil.