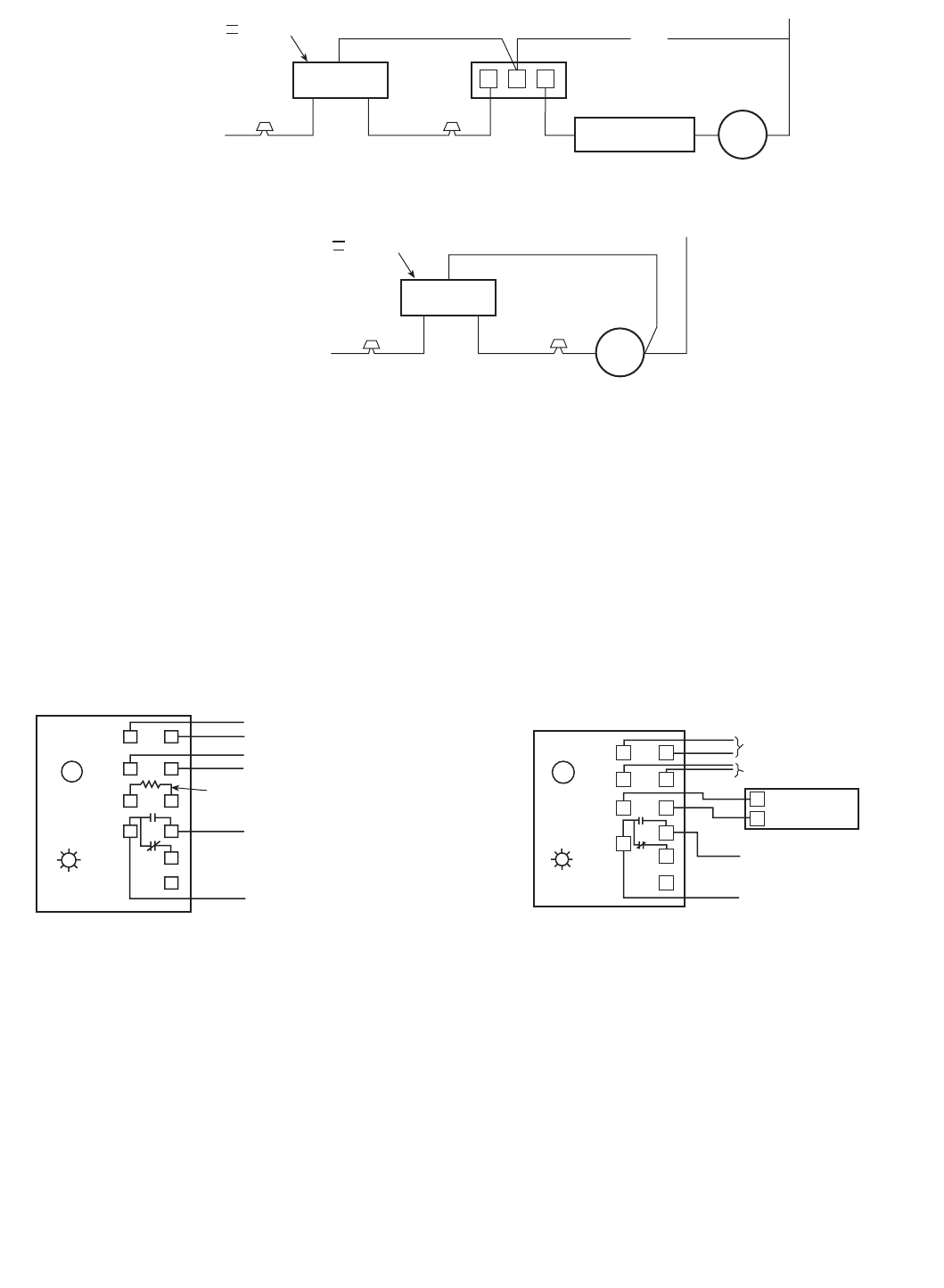

—17—

620 ohm

JUMPER

}

24 VAC SUPPLY FROM

ECONOMIZER CONTROL

SECTION (RED TO TR,

BRN TO TR1)

TO SENSOR MOUNTED

ON BACK OF CONTROL

}

GRAY WIRE FROM

ECONOMIZER HARNESS

RED WIRE FROM

ECONOMIZER SWITCH 3

(NORMALLY CLOSED)

TR

TR1

SO +

+

SR

2

3

1

LED

A

B

C

D

LED

A

B

C

D

TR TR1

SO

SR

2

3

1

+

+

S

+

(HH57AC078

SENSOR)

24 VAC SUPPLY FROM

ECONOMIZER CONTROL

SECTION (RED TO TR,

BRN TO TR1)

TO SENSOR MOUNTED

ON BACK OF CONTROL

GRAY WIRE FROM

ECONOMIZER HARNESS

RED WIRE FROM

ECONOMIZER SWITCH 3

(NORMALLY CLOSED)

1

2

3

BRN

COMPRESSOR

SAFETIES

BRN

CLO

TIME GUARD I I DEVICE

C

OR

CR

T1

T3

T2

TIME GUARD I I DEVICE

C

OR

CR

BRN

T1

T3

T2

HIGH EFFICIENCY 3 TO 12

1

/

2

TON ROOFTOP UNITS

STANDARD EFFICIENCY 3 TO 12

1

/

2

TON ROOFTOP UNITS

LEGEND

Fig. 16 — Time Guard® II Device; 558F036-150

C — Contactor

CLO — Compressor Lockout

CR — Control Relay

NOTE: Switches shown in high enthalpy state. Terminals 2 and 3

close on enthalpy decrease.

Fig. 17 — Wiring Connections for Solid-State

Enthalpy Control (HH57AC077)

NOTES:

1. Remove factory-installed jumper across SR and + before con-

necting wires from HH57AC078 sensor.

2. Switches shown in high outdoor-air enthalpy state. Terminals 2

and 3 close on low outdoor air enthalpy relative to indoor air

enthalpy.

Fig. 18 — Wiring Connections for Differential

Enthalpy Control (HH57AC077 and HH57AC078)