—

7

—

Table 2 — American/European Wire Conversions

LEGEND

START-UP

I. PRELIMINARY CHECKS

1. Check that all internal wiring connections are tight

and that barriers, covers, and panels are in place.

2. Make certain field electrical power source agrees

with unit nameplate rating.

3. Open all service valves.

II. LEAK TEST

Field piping and fan coil must be leak tested by the pressure

method. Use R-22 at approximately 25 psig (172 kPa) backed

up with an inert gas to a total pressure not to exceed

245 psig (1690 kPa).

III. EVACUATE AND DEHYDRATE

Field piping and fan coil must be evacuated and dehydrated.

IV. CHARGE SYSTEM

Release factory charge into system by opening (backseating)

liquid and suction line service valves. Add charge amount as

required for the total system. Refer to separate indoor unit

installation instructions for the required total system charge

when connected to the indoor unit.

V. TO START UNIT

NOTE: When using 538J unit in conjunction with 619 series

fan coils, refer to start-up instructions included with fan coil

for correct start-up procedures.

Be sure that field disconnect is closed. Set room thermostat

below ambient temperature. Operate unit for 15 minutes,

then check system refrigerant charge. See Refrigerant

Charging section on page 8.

Unit compressor starts after a 5-minute delay if equipped

with accessory Time Guard® II device.

SERVICE

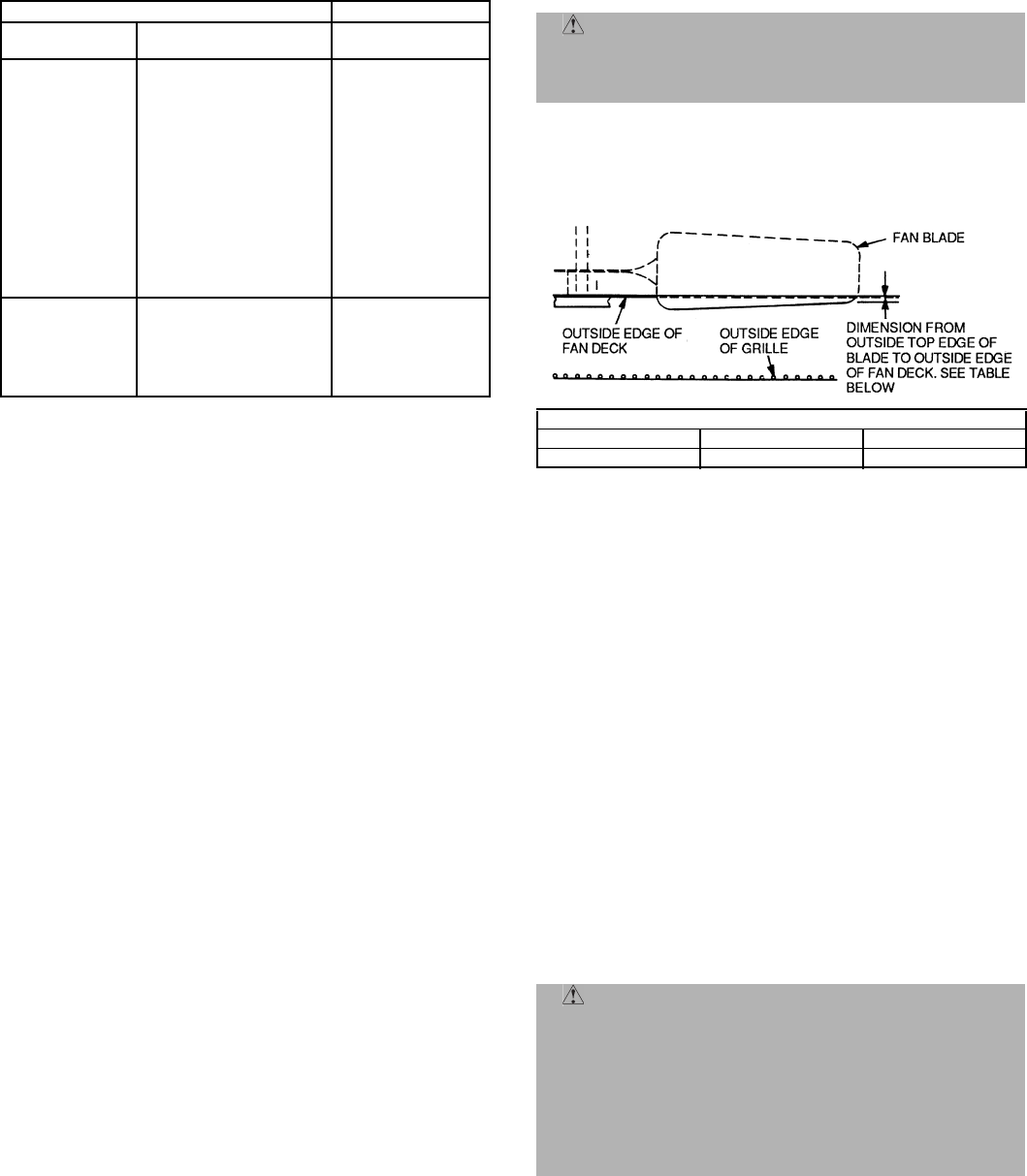

I. OUTDOOR FAN

A reinforced wire mount holds the outdoor fan assembly in

place. See Fig. 7 for proper mounting positions.

II. HIGH-PRESSURE RELIEF VALVE

Valve is located in compressor. Relief valve opens at a

pressure differential of approximately 450 ± 50 psig (3100 ±

345 kPa) between suction (low side) and discharge (high

side) to allow pressure equalization.

III. INTERNAL CURRENT AND TEMPERATURE SENSITIVE

OVERLOAD

Control resets automatically when internal compressor

motor temperature drops to a safe level (overloads may

require up to 45 minutes to reset). When an internal over-

load is suspected of being open, check by using an ohmmeter

or continuity tester.

IV. PUMPDOWN PROCEDURE

The system may be pumped down in order to make repairs

on low side without losing complete refrigerant charge.

To pump down:

1. Attach pressure gage to suction service valve gage

port.

2. Frontseat the liquid line valve.

3. Start unit and run until suction pressure reaches

5 psig (34 kPa).

4. Shut unit off and frontseat suction valve.

5. Depressurize low side of unit and recover refrigerant

following accepted practice.

AMERICAN EUROPEAN

Industry

Standard Size

American Conversion

(mm)

Industry Standard

Size (mm

2

)

18 AWG 0.82 1.0

16 AWG 1.30 1.5

14 AWG 2.08 2.5

12 AWG 3.30 4.0

10 AWG 5.25 6.0

8 AWG 6.36 10.0

6 AWG 13.29 16.0

4 AWG 21.14 25.0

3 AWG 26.65 —

2 AWG 33.61 35.0

1 AWG 42.39 50.0

1/0 AWG 53.49 —

2/0 AWG 67.42 70.0

3/0 AWG 85.00 95.0

4/0 AWG 107.19 120.0

250 kcmil 126.64 150.0

300 kcmil 151.97 —

350 kcmil 177.90 185.0

400 kcmil 202.63 240.0

500 kcmil 253.29 300.0

600 kcmil 303.95 —

AWG — American Wire Gage

kcmil — Thousand Circular Mils

WARNING: Before performing recommended main-

tenance, be sure unit main power switch is off. Failure to

do so may result in electrical shock or injury from rotat-

ing fan blade.

CAUTION: The 538J unit coils hold only the

factory-designated amount of refrigerant. Additional

refrigerant may cause units to relieve pressure

through compressor internal pressure relief valve

(indicated by sudden rise of suction pressure) before

suction pressure reaches 5 psig (34 kPa). If this occurs,

shut off unit immediately, then frontseat the suction

valve and remove and reclaim excess refrigerant fol-

lowing accepted practice.

Fig. 7 — Condenser Fan Mounting Positions

UNIT 538J DIMENSIONS — in. (mm)

018 024-036 048-060

0.433 (11) 0.709 (18) 0.16 (4)