5

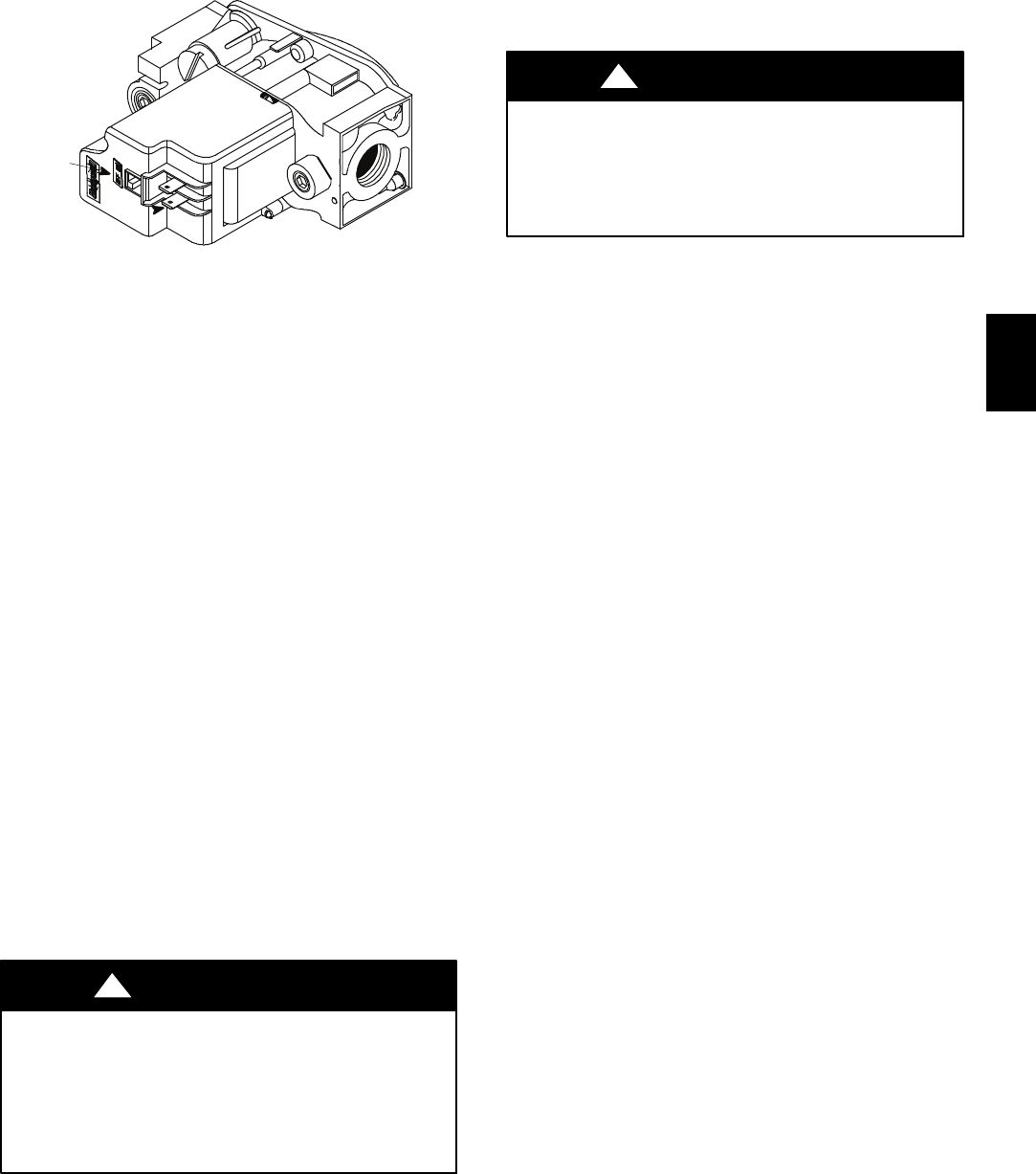

1/4” Spade

Connection

Single Stage

On\Off

toggle

switch

INLET

OUTLET

A07694

Fig. 3 -- Gas Control Valve

2. Have someone check the structure frequently during cold

weather to make sure it is warm enough to prevent pipes

from freezing. Instruct them to call a qualified service

agency to call to provide service, if required.

-- o r --

3. Install a reliable remote sensing device that will notify

somebody of freezing conditions within the home.

Winter Shutdown (90+ Furnaces)

If you go away during the winter months and do not leave the heat

on in your home, the plastic transition box and the condensate trap

on the furnace must be protected from freeze damage. (See Fig. 2)

1. Disconnect the 1/2” I.D. rubber hose from the vent drain fit-

ting (or tee) that is located downstream of the combustion

blower. Insert a funnel into the hose and pour four (4)

ounces of sanitary type (RV) antifreeze into the condensate

trap. Reconnect the 1/2” I.D. rubber hose to the stub on the

vent drain fitting. Secure with the hose clamp.

2. Disconnect the 5/8” I.D. rubber hose from the condensate

trap. Insert a funnel into the hose and pour four (4) ounces

of sanitary type (RV) antifreeze into the plastic transition

box. Squeeze the hose together near the end and quickly re-

connect the 5/8” I.D. rubber hose to the stub on the con-

densate trap. Secure with the hose clamp.

3. When you return home, your furnace will be ready to start,

as it is not necessary to drain the antifreeze from the furnace.

Furnace Maintenance

Have your furnace inspected and serviced on an annual basis

(before the heating season) by a qualified service agency .

Labeling

FIRE OR EXPLOSION HAZARD

Failure to follow this warning could result in personal injury

or death.

Label all wires prior to disconnection when servicing controls.

Verify proper operation after servicing. Only qualified service

agencies should attempt electrical service.

!

WARNING

Pressure Switches

During regular yearly maintenance, check for c racks in any tubes

on the pressure switches.

ELECTRICAL SHOCK HAZARD

Failure to follow this warning could result in personal injury

or death.

Turn off e lectrical power to furnace before performing any

maintenance or removing panels or doors.

!

WARNING

Air Filters/Monthly

The air filter(s) should be inspected at least monthly and cleaned or

replaced as required. There are many types of filters that are

commonly used. Washable filters (constructed of aluminum mesh,

foam, or r einforced fibers) may be cleaned by soaking in mild

detergent and rinsing with water. The fiberglass disposable type

should be REPLACED before it becomes clogged. Other filter

types should be serviced in accordance with the manufacturer’ s

recommendations.

Remember that dirty filters are the most common cause of

inadequate heating or cooling performance.

Replacement Filters

If the f ilter is not located at or within the furnace, it should be

located somewhere in the return--air duct system.

The recommended sizes and types of filters that may be used with

your furnace are based on the furnace’s heating gas input rate (and

cooling system capacity, if so equipped).

Replacement filters should be of the same type and size as the

original filters, to ensure adequate air flow and filtering. A

disposable low velocity filter can be replaced with a washable high

velocity type. Do not replace a high velocity filter with a

disposable low velocity filter, except as permitted below.

If a cleanable (high--velocity) filter(s) is to be replaced with a

disposable (low--velocity) filter(s), the airflow area of the filter(s)

must be doubled (i.e., a second filter of the same size must be

installed so that only half of the air goes through each filter). A

second return--air duct to the furnace may be required in which to

install the second filter . Modification of a furnace installation shall

comply with the local installation code and the furnace installation

instructions, and shall be made only by a Qualified Service

Agency.

NOTE: Some filters are marked with an arrow to indicate the

proper direction of air flow through the filter. The a ir flow

direction will be towards t he blower motor. Make sure filter is

installed correctly.

NOTE: Some units are equipped with filter rack.

Filter Replacement -- Upflow

The filter may be installed inside the bottom of the furnace blower

compartment, or the filter(s) rack may be installed under the

furnace or on either or both sides of the furnace. A plastic end

cap(s) is i nserted in the filter rack(s) a fter the filter(s) is installed.

The end cap keeps air from escaping around the open end of the

filter rack. See Fig. 4 and Fig. 5 for side and bottom locations.

Rack end cap is similar for bottom mounted filter rack.

359AAV