9

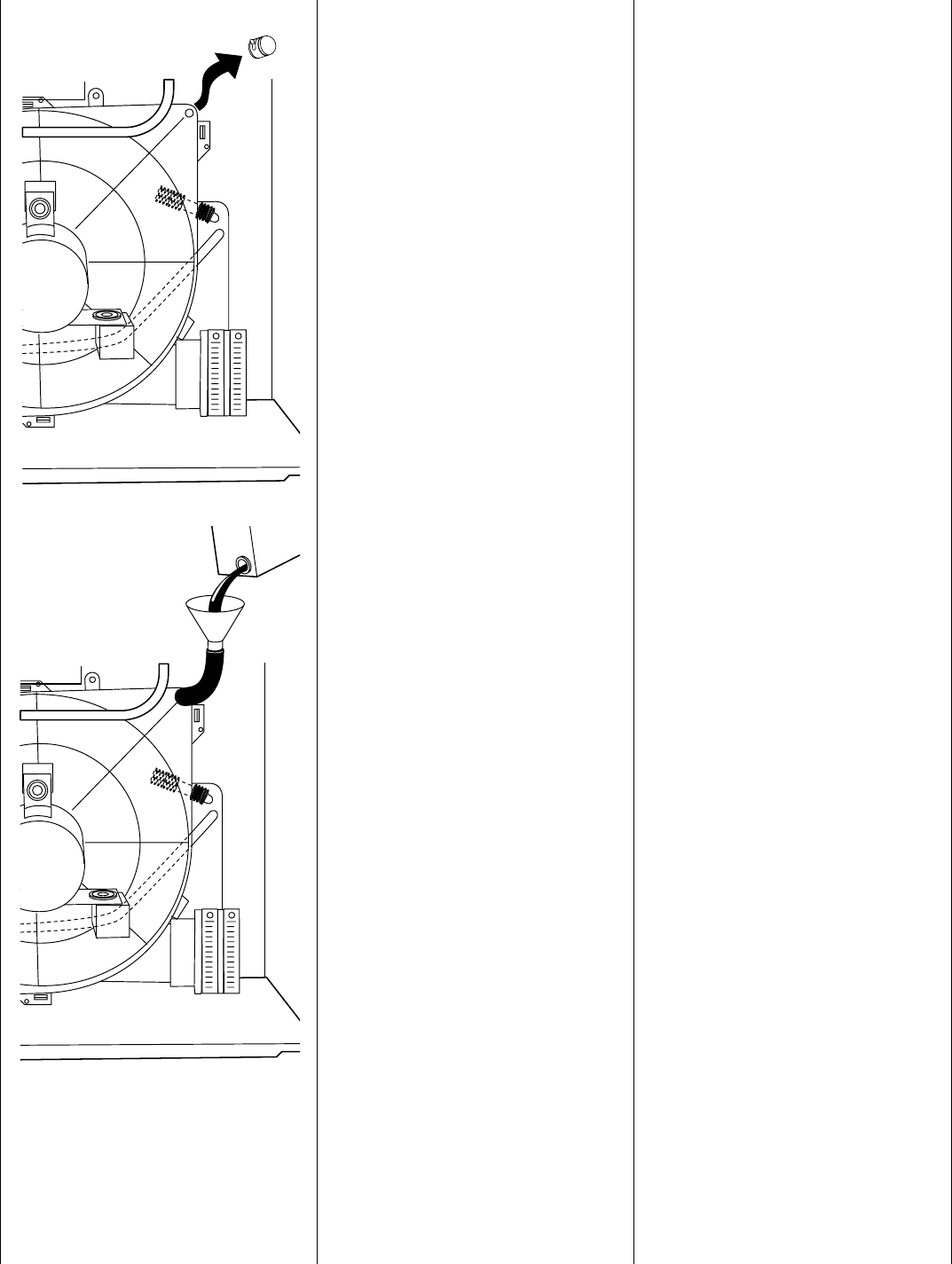

32

33

7. Pour 1 quart of antifreeze into

funnel/tube. Antifreeze should run

through inducer housing, overfill

condensate trap, and flow into

open field drain. (See Fig. 33.)

8. Remove funnel and tube from

inducer housing and replace drain

connection cap and clamp.

9. Replace main furnace door.

(See Fig. 28.)

A CHECK-UP

CHECKLIST

Your furnace represents an important

investment in your family’s comfort

and your home’s value. To keep it

performing properly and as a preven-

tative to future problems, have a trained

service specialist give your furnace a

professional check-up annually. The

following checklist can be used as a

guideline to proper service:

• Inspect all flue gas passages, burn-

ers, heat exchangers, coupling

box(es), and inducer assembly.

• Inspect all combustion-air and vent

piping inside structure and vent pipe

termination outside the structure.

• Check gas pipes leading to and

inside of your furnace for leaks.

• Inspect and clean the blower motor

and wheel.

NOTE: The inducer and blower motors

are pre-lubricated and require no addi-

tional lubrication. These motors can be

identified by the absence of oil ports on

each end of the motor.

• Inspect and change or clean air fil-

ter(s) if necessary.

• Inspect all supply- and return-air

ducts for obstructions, air leaks, and

insulation. Remedy any problem when

necessary.

• Inspect the return-air duct connec-

tion(s) at the furnace to ensure it is

physically sound, sealed to the furnace

casing, and terminates outside the

space containing the furnace.

• Inspect electrical wiring, connec-

tions, and components for loose

connections.

• Perform an operational checkout to

determine whether your furnace is

working properly and if it requires

adjustments.

• Inspect all condensate drain tubes

and condensate trap assembly for

leaks. The condensate removal system

should be cleaned annually by a quali-

fied service agency. Refer to the Ser-

vice and Maintenance Instructions for

further information.

• Examine the physical support of the

furnace. The support should be sound

with no cracks, sagging, gaps, etc.

around the base.

• Check furnace for any obvious signs

of deterioration.

BEFORE YOU

REQUEST A

SERVICE CALL

If your furnace is not operating or not

performing properly, you may save

the expense of a service call by check-

ing a few things yourself before calling

for service.

FOR INSUFFICIENT AIRFLOW:

• Check for dirty air filter(s).

• Check for blocked return-air or sup-

ply-air grilles throughout your home.

Ensure they are open and unobstructed.

If problem still exists, call your dealer

for service.

IF FURNACE FAILS TO OPERATE:

Follow this checklist step by step,

advancing to the next step only if fur-

nace fails to start.

• Check thermostat for proper tem-

perature. Is thermostat set above room

temperature?

• Is thermostat set to HEAT?

• Check fuses and circuit breakers. Is

electrical supply on?

• Is manual shutoff valve in gas supply

pipe in open position? (Follow start-up

procedures if you open gas valve.)

NOTE: Turn off electrical supply

before continuing with checklist.

• Is control switch or knob on gas

valve in ON position? (Follow start-up

procedures if you must reset switch or

knob to ON position.)

• Check manual reset flame rollout

switch located on the burner box.

(See Fig. 2.) If furnace has experienced

high temperature conditions, this

switch will shut off the furnace. Reset

it by pushing the button on the switch.

If it trips again, shut down the furnace

and call for service. See “Shutting

Down Your Furnace” section in this

manual.

• Check for obstructions around the

vent termination.

If your furnace still fails to operate, call

your service representative.

For your convenience, record the fur-

nace product and serial numbers on

page 2. Should you ever require ser-