Low initial cost, reliable operating effi ciency

deliver substantial return on investment

Bryan EB Series Boiler Specifi cations

NOMINAL OUTPUT STEAM APPROX.

BOILER INPUT

OUTPUT SHIP WT.

MODEL MBH (KW)

MBH (KW)*

BHP*

LBS./HR** (KG) LBS. (KG)

EB-75 3,200 (938) 2,560 (750) 75 2,639 (1,197) 5,810 (2,635)

EB-100 4,200 (1,230) 3,360 (984) 100 3,463 (1,570) 7,110 (3,225)

EB-125 5,250 (1,538) 4,200 (1,230) 125 4,329 (1,963) 8,300 (3,765)

EB-150 6,300 (1,845) 5,040 (1,476) 150 5,195 (2,356) 8,420 (3,819)

EB-175 7,325 (2,146) 5,860 (1,717) 175 6,041 (2,740) 11,175 (5,069)

EB-200 8,500 (2,490) 6,800 (1,992) 200 7,010 (3,179) 11,305 (5,128)

EB-240 10,000 (2,930) 8,000 (2,344) 240 8,247 (3,740) 14,455 (6,557)

NOTES: * * Nominal output based on boiler industry standard of 80% of input. Actual combustion effi ciencies will be fuel dependent.

** Lbs. steam per hour from and at 212° F.

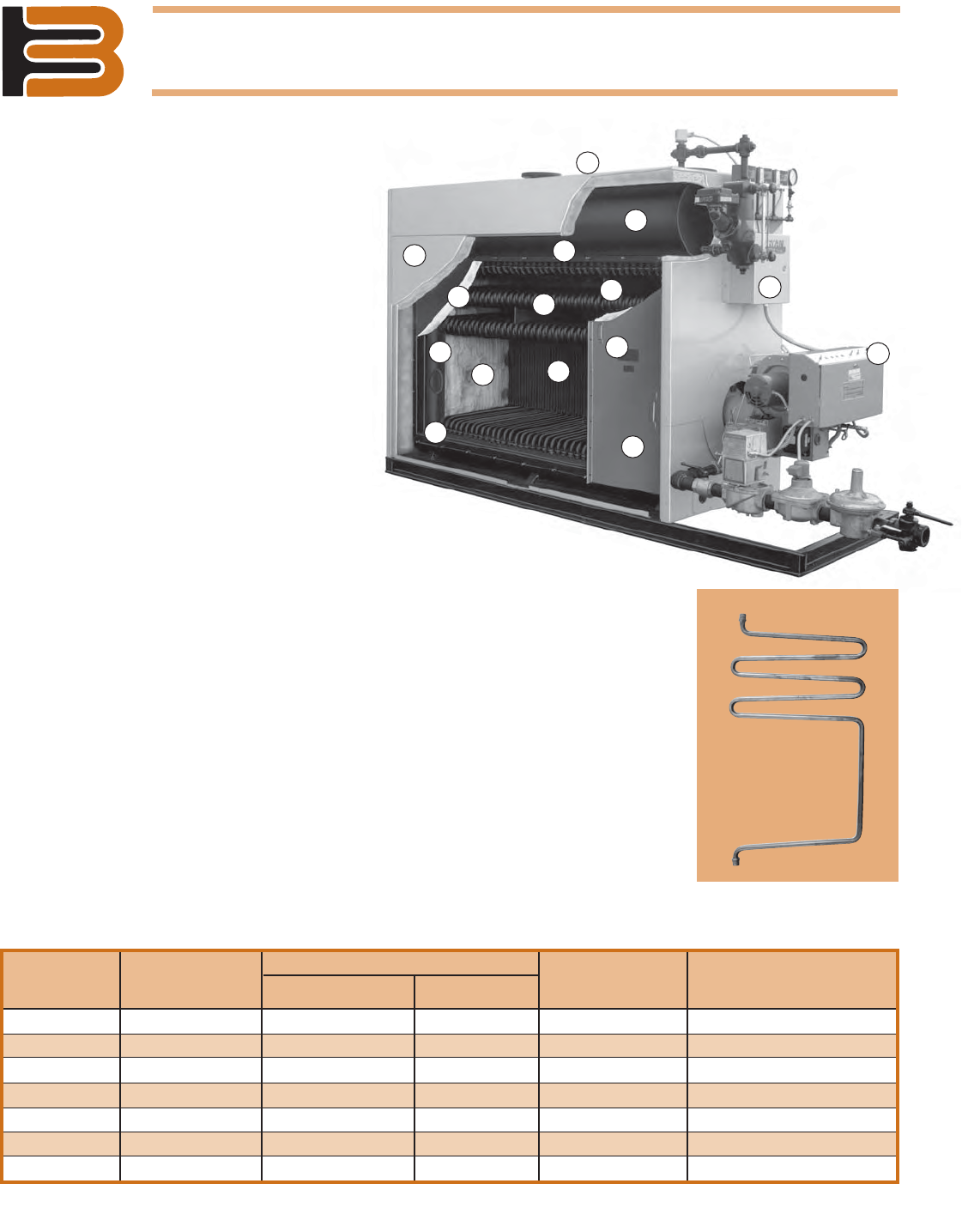

L. Internal water-cooled

furnace with low heat

release rate.

M. Steam boilers with

extra large drum with high

steam release area ensure

stable water level and dry

steam.

N. Pressurized design:

inner fi reside casing con-

structed of heavy gauge

steel, completely seal-

welded, lined with high

temperature insulation

and refractory.

J

F

A

E

C

I

B

D

N

L

K

D

M

Quality Construction Features:

A. Water side or steam side interior ac cessible

for clean out and inspection, front and rear

open ings, upper and lower drums.

B. Large volume water leg down comers pro-

mote rapid internal circulation, temperature

equalization and effi cient heat transfer.

C. Boiler tube and furnace area access panels:

heavy gauge steel casing with 2؆ high tem-

perature ceramic fi ber and insulation, bolted

and tightly sealed to boiler frame.

D. Flame observation port at rear of boiler.

E. Single side access; combustion chamber, tubes and

burner head are completely accessible from one side

simplifying maintenance and minimizing fl oor space.

F. Minimum sized fl ue vent.

G. Control panel: all controls installed with connections

to terminal strip.

H. Forced draft, fl ame retention head type burner. Effi -

cient combustion of oil or gas, plus quiet operation.

I. Heavy steel boiler frame, built and stamped in accor-

dance with the appropriate ASME Boiler Code.

J. Heavy gauge steel boiler jacket with rust-resistant

zinc coating and enamel fi nish, insulated with 1½؆

fi berglass to ensure exceptionally cool outer surface.

K. Bryan bent water tubes are flexible, individually

replaceable without welding or rolling. Never more

than two tube configurations.

G

H

• True “fl exible water tube” design

• High quality steam for heat

or process

• Pressurized fi ring for maximum

performance