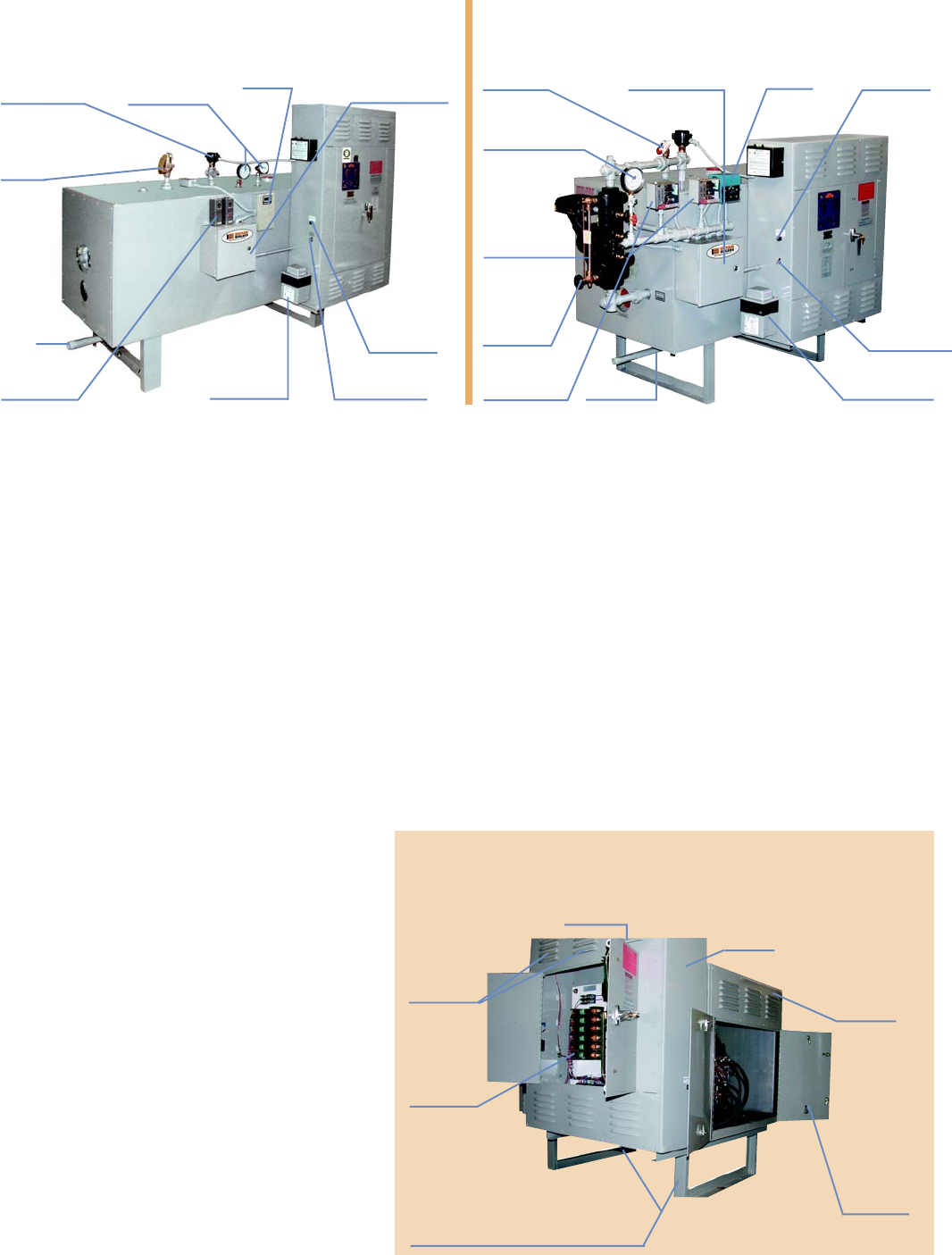

Water boiler trim and controls

Steam boiler trim and controls

Drain

(2) High

limit controls

Pressure and

temperature

gauges

Operating

control

Control

circuit fuse

Control circuit

on-off switch

Control

circuit

transformer

Modulating step

controller (units

over 60 KW)

ASME

relief

valve

Probe type

low water

cutoff control

Control circuit

transformer

ASME relief

valve

(2) High

limit controls Blowdown

Low water

cutoff and

pump

control

Water level

gauge glass

Pressure gauge

Modulating step

controller (units

over 60 KW)

Control

circuit fuse

Control circuit

on-off switch

Standard Equipment Supplied:

HOT WATER DESIGN BOILERS:

Model “W” (150# ASME Design)

Thermometer and pressure gauge, Operating immer-

sion aquastat, 2 high limit aquastats, Low water

cutoff, Relief valve, Metal jacket with 2؆ fiberglass, 75

W/D Incoloy sheathed elements with pressure

connector power lugs. Control panel with Key lock,

On/Off control switch, 120 volt control transformer

(fused), Magnetic contactors with 120 volt coil,

Individual circuit fusing, Step indicating lamps, First

on/first off progressive step controller (3 thru 40

steps), National Board Inspection and UL Label.

Model “WT”

Includes items in Model “W” design, plus Indirect heat

exchanger — Max. discharge, Heat exchanger relief

valve, Expansion tank, Boiler fill and drain valves and

Boiler drain cock. (See Form 4800)

Optional Equipment Available:

Power panel door electric interlock. Preheat

switch. Flow switch. Manual reset controls.

Manual blowdown valve. Automatic

blowdown with 24 hour time clock. Alarms.

Indicating lights. Larger connection for heat

pump applications.

Other Designs Available:

1) BH – Our upgrade to the BE Series

(Form 3200)

2) WT – Indirect Hot Water Supply Heaters

(Form 4800)

3) Energy Selector Boiler – Electric plus gas,

oil or gas/oil. A boiler with multiple energy

source choice (Form 3500)

Standard Equipment Supplied:

STEAM DESIGN BOILERS:

Model “S” (15# ASME Design)

Model “Q” (150# ASME Design)

Steam pressure gauge w/gauge clock, Operating

pressure control, 2 high limit pressure controls,

Combination low water cutoff and pump control,

Auxiliary low water cutoff, Relief valve, Water glass set,

Metal jacket with 2؆ fiberglass, 75 W/D Incoloy

sheathed elements with pressure connector power

lugs. Control panel with: Key lock, On/off control

switch, 120 volt control transformer, Magnetic

contactors with 120 volt coil, Individual circuit fusing,

Step indicating lamps, First on/ first off progressive

step controller (3 thru 40 steps), National Board

Inspection and UL Label.

Standard Design Features

Elevated legs integral with structural

frame and extended rails for positive

support of both pressure vessel and

heavy duty power panel cabinet.

Each

branch

circuit is

fused

individually

Hinged

door for

access to

vessel,

ASME and

elements

16 gauge

jacketing all

around

structural

frame; zinc

coated, rust

resistant

primer,

enamel

finished

Heavy duty,

11 gauge

power

panel

cabinet

Single point

connection entrance

Louvered

panel

cover for

proper

cooling air

circulation

Operating

control