13

MAINTENANCE

ENGINE AND ENGINE PARTS

We recommend that you see an authorized Briggs & Stratton Service Dealer for all maintenance and service of the engine

and engine parts. Use only genuine Briggs & Stratton parts.

WARNING

If you perform any maintenance on the engine, first disconnect the spark plug wire

from the spark plug, and disconnect the battery at the negative terminal (electric

starter engines only) to prevent unintentional sparking. Unintentional sparking can

result in fire or electric shock. Unintentional start-up can result in entanglement,

traumatic amputation or laceration. Use only correct tools.

WARNING

• Do not strike the flywheel with a hammer or hard object because the flywheel may

later shatter during operation.

• Do not tamper with governor spring, links or other parts to increase engine speed.

CLEANING DEBRIS

CAUTION: Do not use water to clean engine parts.

Water could contaminate fuel system. Use a brush

or dry cloth.

Engine parts should be kept

clean to reduce the risk of

overheating and ignition of accu-

mulated debris. This is especial-

ly important if cutting tall grass.

WARNING

Daily or before every use, clean grass, chaff or accumu-

lated debris from engine. Keep linkage, spring and controls

clean. Keep area around and behind muffler free of any

combustible debris.

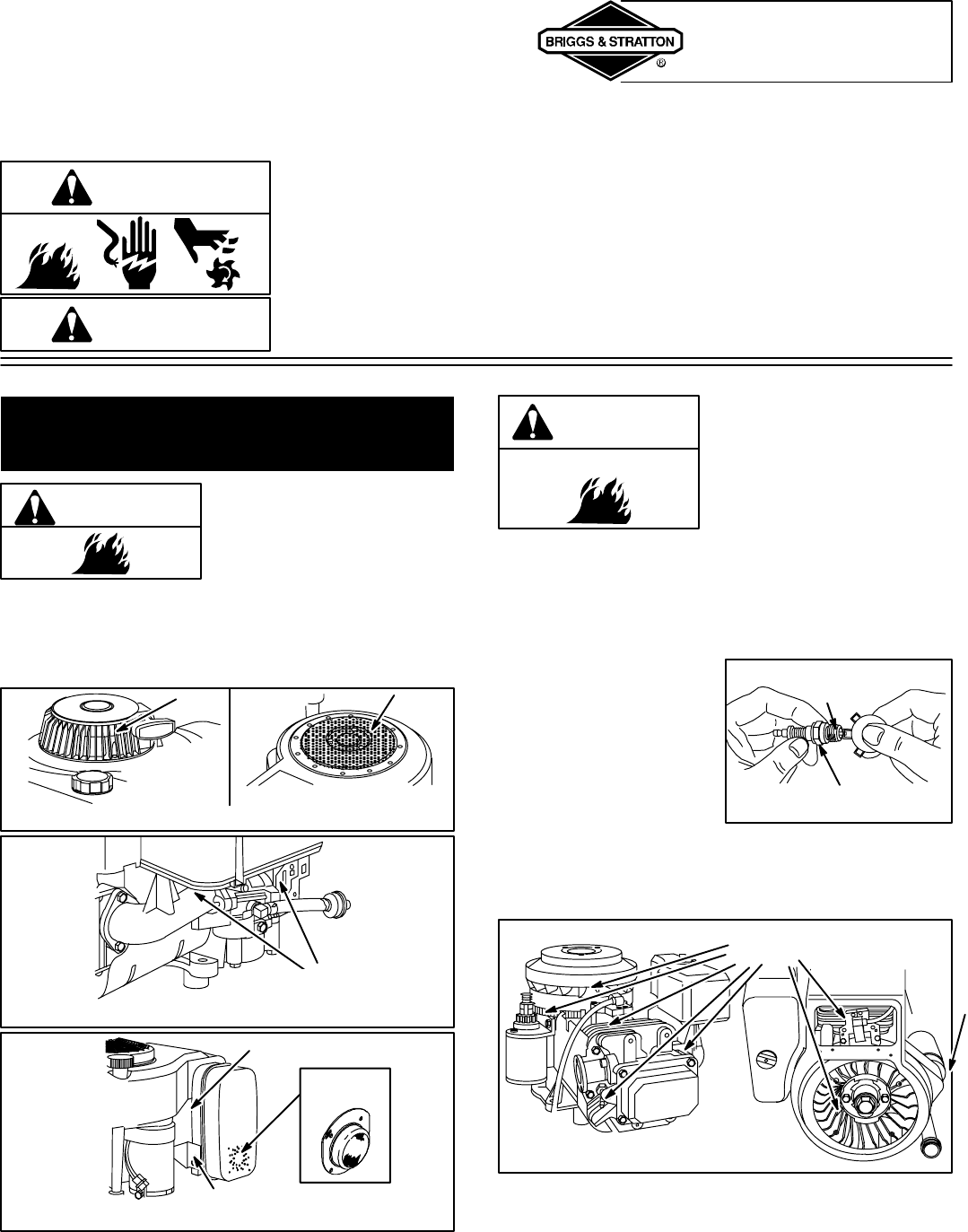

Finger Guard

CLEAN

CLEAN

Linkage, Springs, Controls

Muffler, Spark Arrester

Rotating Screen

CLEAN

CLEAN

SPARK

ARRESTER

CLEAN

MUFFLER

Replacement parts for the

muffler must be the same and

installed in the same position

as the original parts, other-

wise fire can occur.

If muffler is equipped with

spark arrestor screen, re-

move screen for inspection. Replace screen if damaged or

plugged.

WARNING

SPARK PLUG

Use only Briggs & Stratton Spark Tester (part number

19368) to check for spark.

Note: In some areas, local

law requires using resistor

spark plug to suppress

ignition signals. If this en-

gine was originally

equipped with resistor

spark plug, use same type

for replacement.

.030” (0.76 mm)

WIRE GAGE

RESISTOR P/N 491055

AIR COOLING SYSTEM

We recommend that after every 100 hours you have an

authorized Briggs & Stratton Service Dealer clean the air

cooling system.

CLEAN OUT

CHAFF AND

DEBRIS

VALVE CLEARANCE

Check valve clearance yearly. (See Tune-up Specifications

on page 6).